Spherical surface-engaged universal multi-section synchronous transmission mechanism

A synchronous transmission and meshing technology, applied in the directions of manipulators, claw arms, manufacturing tools, etc., can solve the problems of inability to realize multi-joint synchronous motion, inability to realize spatial motion, and increased structural complexity, and achieve a small number of driving sources and reduce control. Difficulty, the effect of reducing the drive load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

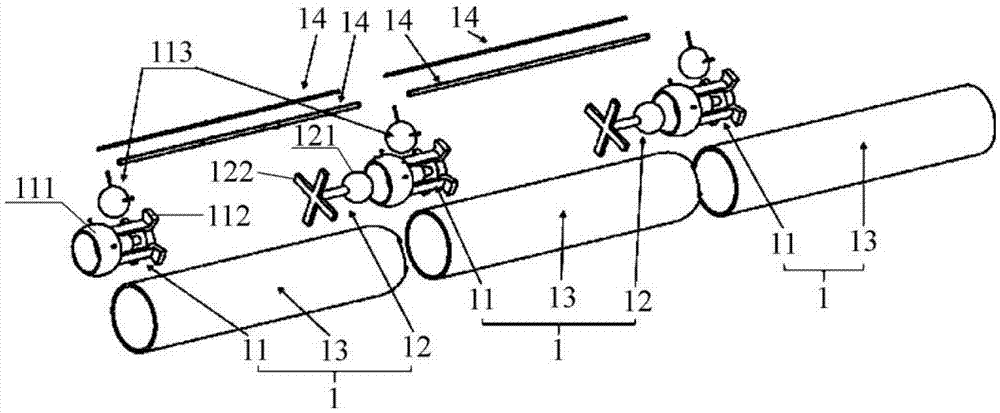

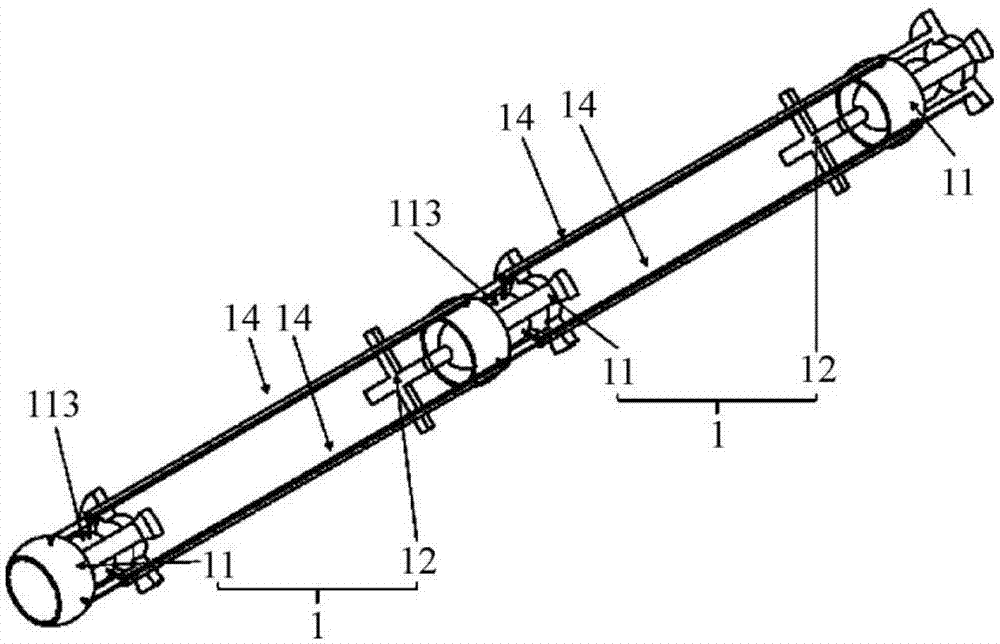

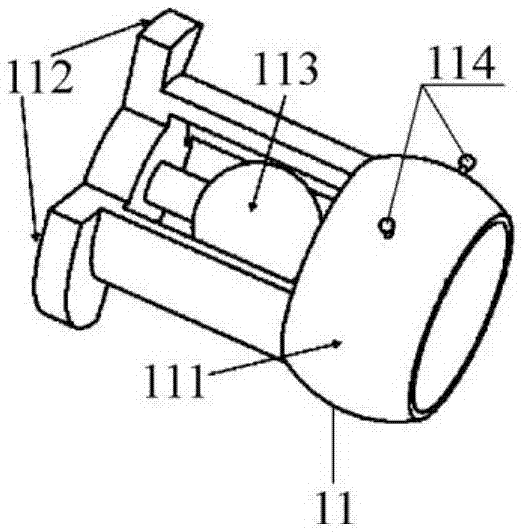

[0031] A spherical meshing universal multi-joint synchronous transmission mechanism, including three boom joints 1, such as Figure 1 to Figure 6 As shown, the specific structure is:

[0032] The arm sections 1 are connected sequentially. The arm sections 1 at the head end and the middle end include a front connecting piece 11 and a rear end connecting piece 12. The arm section 1 at the rear end includes a front connecting piece 11. The arm section 1 also includes an arm shell 13. Part 11 is arranged on the front end of arm shell 13, and rear-end connecting piece 12 is arranged on the rear end of arm shell 13, and front-end connecting piece 11 comprises a sphere or a spherical cap, and rear-end connecting piece 12 comprises and front-end connecting piece 11 forms spherical surface Engaged spherical crown shells or spheres; when the number of arm sections 1 is more than one, adjacent arm sections 1 are connected through the engagement between the spheres and the spherical crown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com