Lifting device of overturning machine

The technology of a lifting device and a turning machine is applied in the directions of conveyor objects, transportation and packaging, which can solve the problems of skipping teeth and difficult to meet the transfer of the car body, and achieve the effect of simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

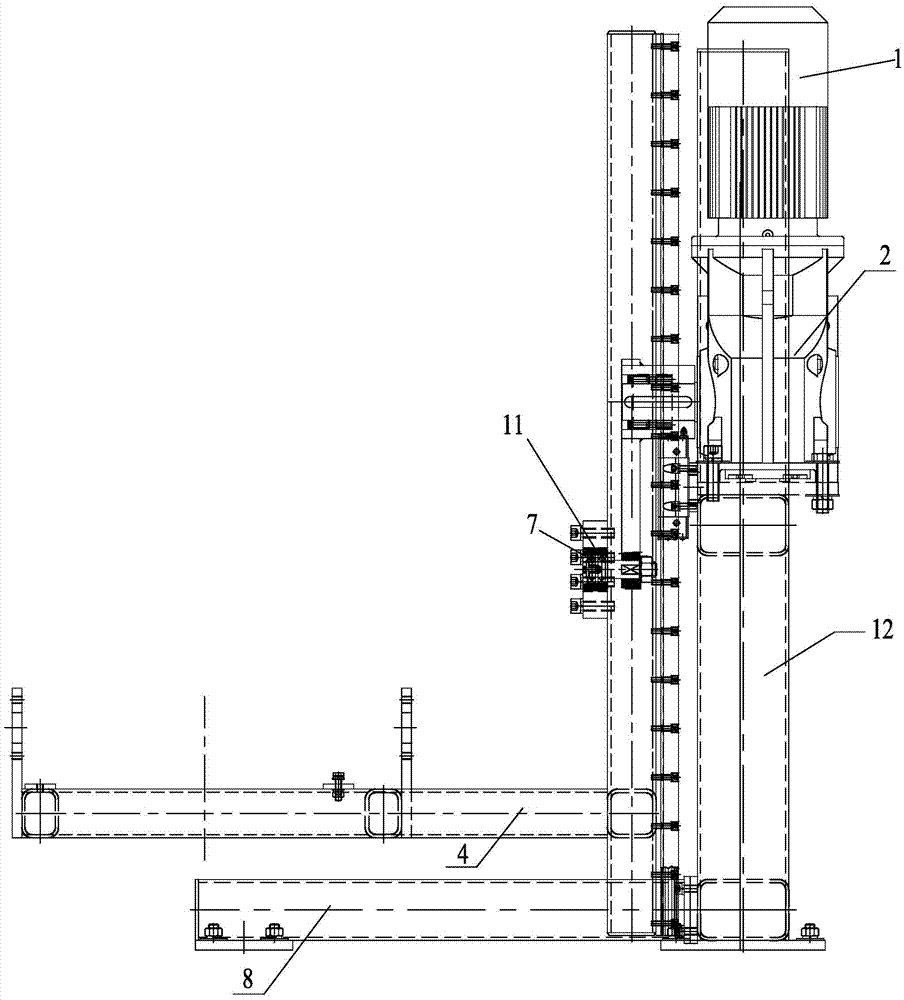

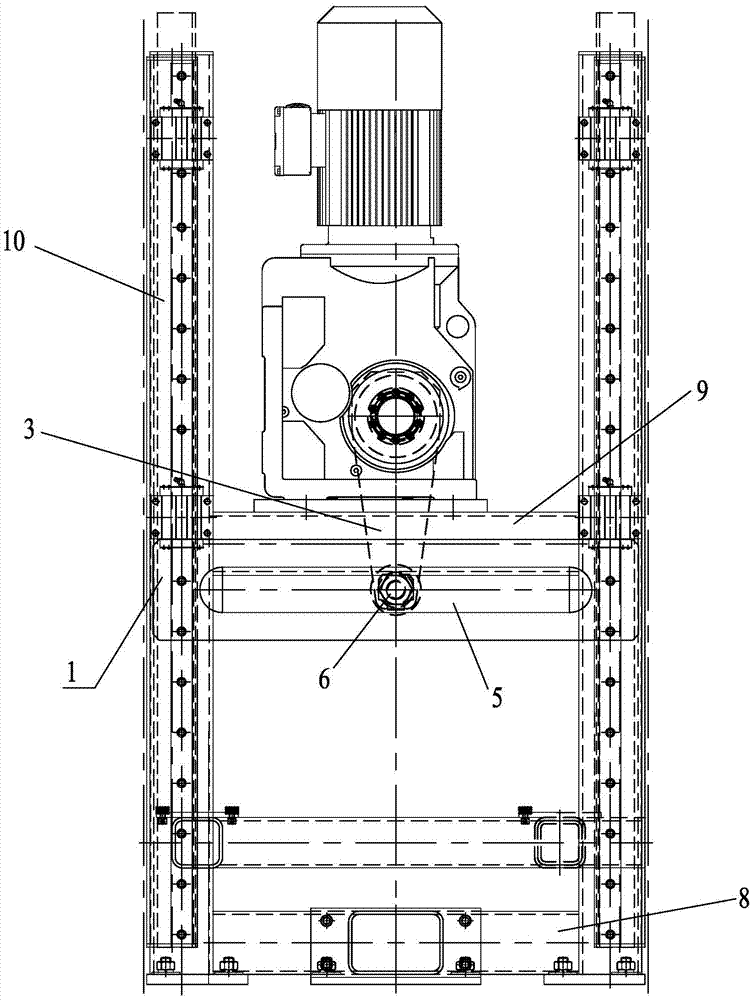

[0012] figure 1 Among them, including lifting motor 1, reversing gear box 2, crank 3, lifting frame 4, guide groove 5, connecting shaft 6, bearing 7, adjusting gasket 8, beam 9, slide rail 10, roller ring 11, column 12, etc. .

[0013] like figure 1 As shown, the present invention is a lifting device for a turning machine, comprising two vertical columns 12 arranged parallel to each other, the lower ends of the two vertical columns 12 are connected by adjusting gaskets 8, and the middle parts of the two vertical columns 12 are fixed with a crossbeam 9, and the crossbeam 9 The reversing gear box 2 is installed on the top, and the input end of the reversing gear box 2 is fixed with a lifting motor 1; the column 12 is provided with a slide rail 10, and the lifting frame 4 is slidably arranged on the slide rail 10, and the lifting frame 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com