Surface amphiphilic nano-molybdenum disulfide hydrogenation catalyst and preparation method and application thereof

A technology of nano-molybdenum disulfide and hydrogenation catalyst, which is applied in the direction of physical/chemical process catalyst, molybdenum sulfide, chemical instruments and methods, etc. It can solve problems that do not belong to the category of chemical synthesis, and achieve good application prospects and good catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

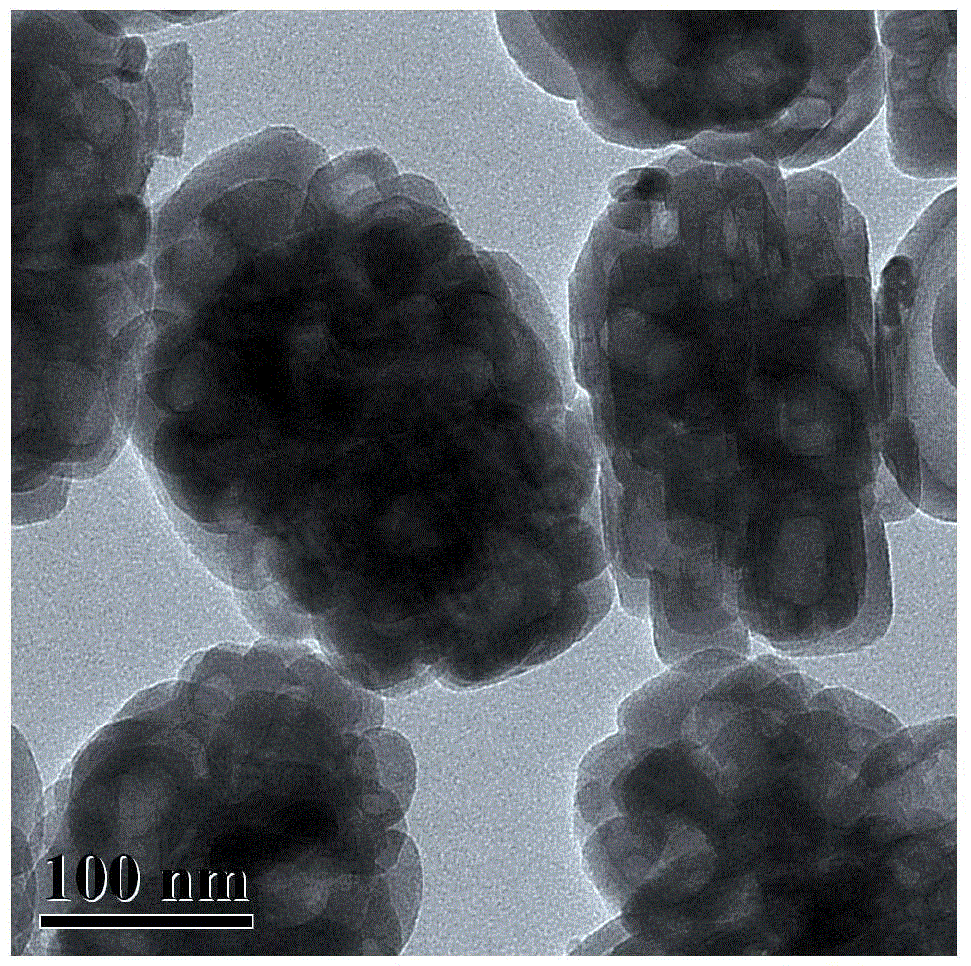

[0030] This example illustrates the method of using 1-ethyl-3-methylimidazolium tetrafluoroborate to prepare surface amphiphilic nanomolybdenum disulfide hydrogenation catalyst.

[0031] Add a certain amount of sodium molybdate to 500mL deionized water to make the concentration of molybdenum reach 0.01mol / L, stir until uniform; add sodium sulfide aqueous solution to the above mixture, so that sodium sulfide: sodium molybdate (molar ratio) reaches 2.5: 1. Stir until uniform, react at 80°C for 12 hours; add hydroxylamine hydrochloride to the above mixture, make hydroxylamine hydrochloride: sodium molybdate (molar ratio) reach 4:1, stir until uniform; add ionic liquid 1-B to the above mixture Base-3-methylimidazolium tetrafluoroborate, make 1-ethyl-3-methylimidazolium tetrafluoroborate: sodium molybdate (molar ratio) reach 24:1, stir until uniform, configure as initial reaction Mixture; the initial reaction mixture was transferred to a high-pressure synthesis kettle, and crystall...

Embodiment 2

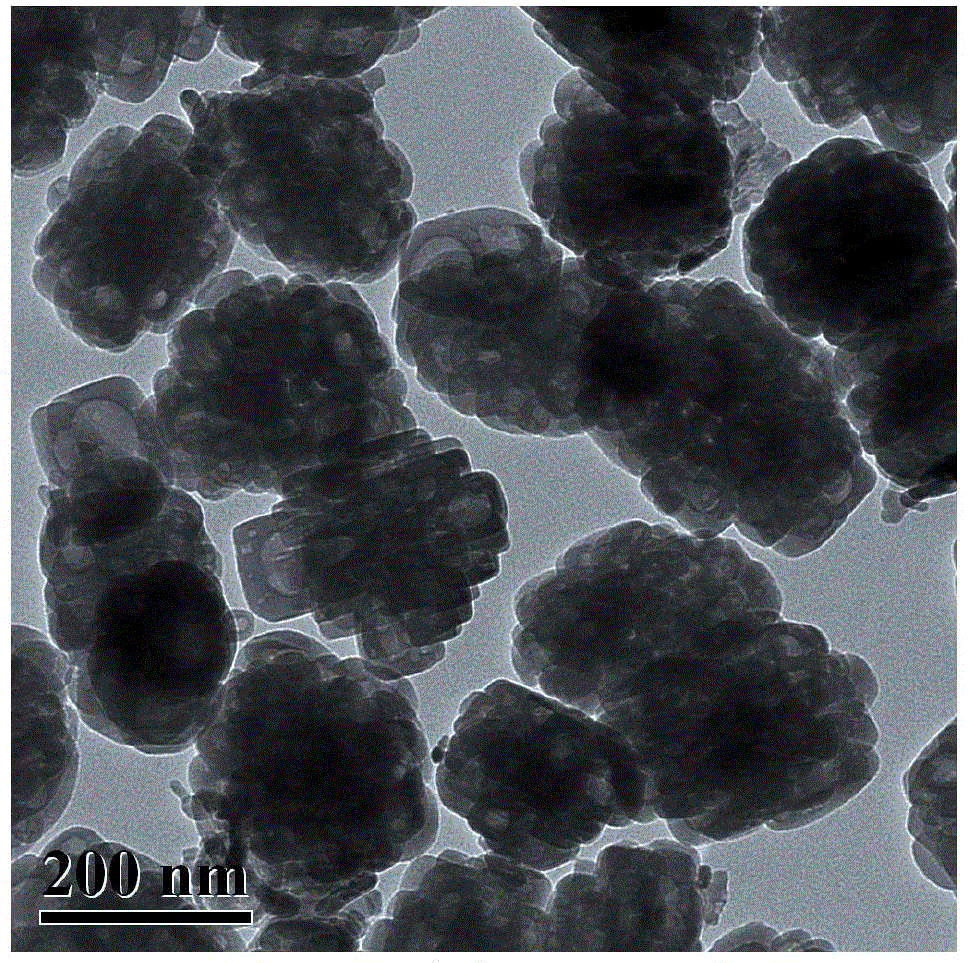

[0034] This example illustrates the method of using 1-butyl-3-methylimidazolium hexafluorophosphate to prepare surface amphiphilic nanomolybdenum disulfide hydrogenation catalyst.

[0035]Add a certain amount of potassium molybdate to 500mL deionized water to make the concentration of molybdenum reach 0.015mol / L, stir until uniform; add potassium sulfide aqueous solution to the above mixture, make potassium sulfide: potassium molybdate (molar ratio) reach 4: 1. Stir until uniform, react at 40°C for 24 hours; add potassium borohydride to the above mixture to make potassium borohydride: potassium molybdate (molar ratio) reach 3:1, stir until uniform; add ionic liquid 1 to the above mixture -Butyl-3-methylimidazolium hexafluorophosphate, make 1-butyl-3-methylimidazolium hexafluorophosphate: potassium molybdate (molar ratio) reach 18:1, stir until uniform, configure as initial reaction Mixture; the initial reaction mixture was transferred to a high-pressure synthesis kettle and cr...

Embodiment 3

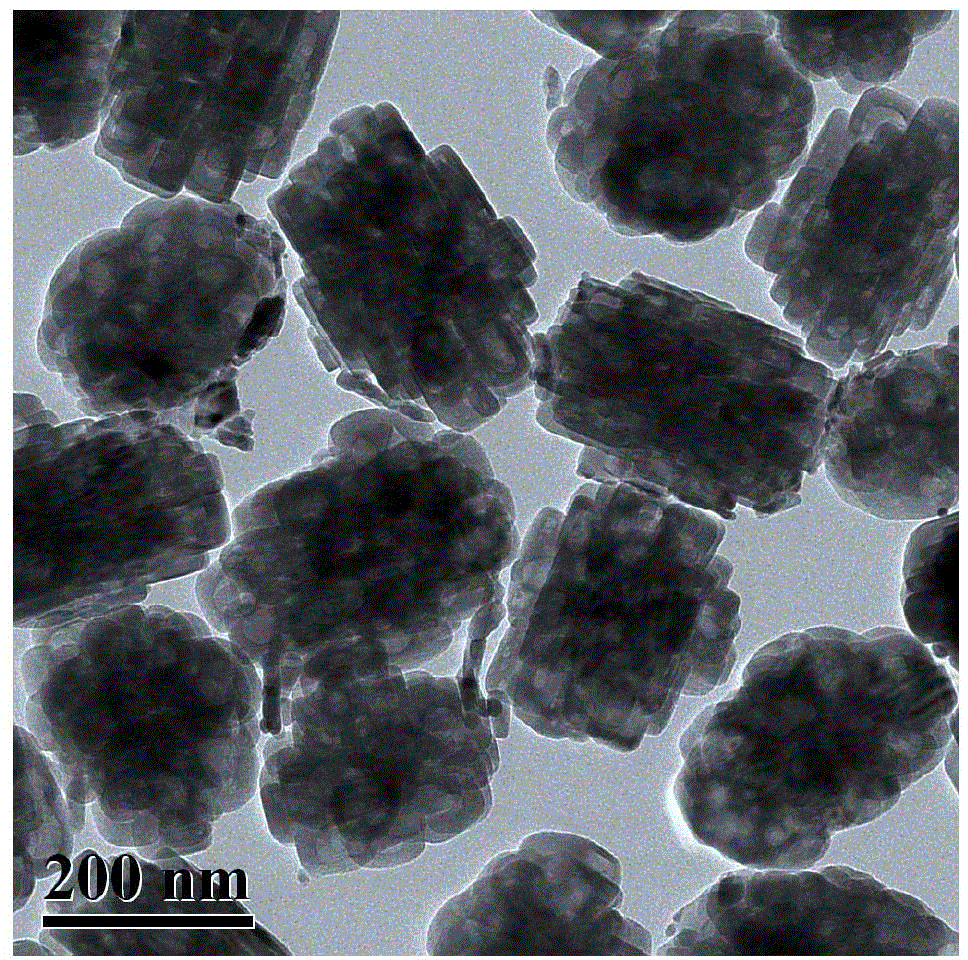

[0037] This example illustrates the method of using 1-propyl-3-methylimidazolium bromide salt to prepare surface amphiphilic nano molybdenum disulfide hydrogenation catalyst.

[0038] Add a certain amount of molybdenum nitrate to 500mL deionized water so that the concentration of molybdenum reaches 0.5mol / L, and stir until uniform; add hydrogen sulfide aqueous solution to the above mixture, so that hydrogen sulfide:molybdenum nitrate (molar ratio) reaches 2:1, Stir until uniform, react at 50°C for 20h; add polyethyleneimine to the above mixture to make polyethyleneimine:molybdenum nitrate (molar ratio) reach 2:1, stir until uniform; add ionic liquid 1- to the above mixture Propyl-3-methylimidazolium bromide, make 1-propyl-3-methylimidazolium bromide: molybdenum nitrate (molar ratio) reach 0.01:1, stir until uniform, configure initial reaction mixture; Initial reaction mixture Transfer to a high-pressure synthesis kettle and crystallize at 160°C for 40h. After the crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com