Side plate assembly and electric appliance

A side panel and component technology, applied in the field of side panel components and electrical appliances, can solve problems such as electrical hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

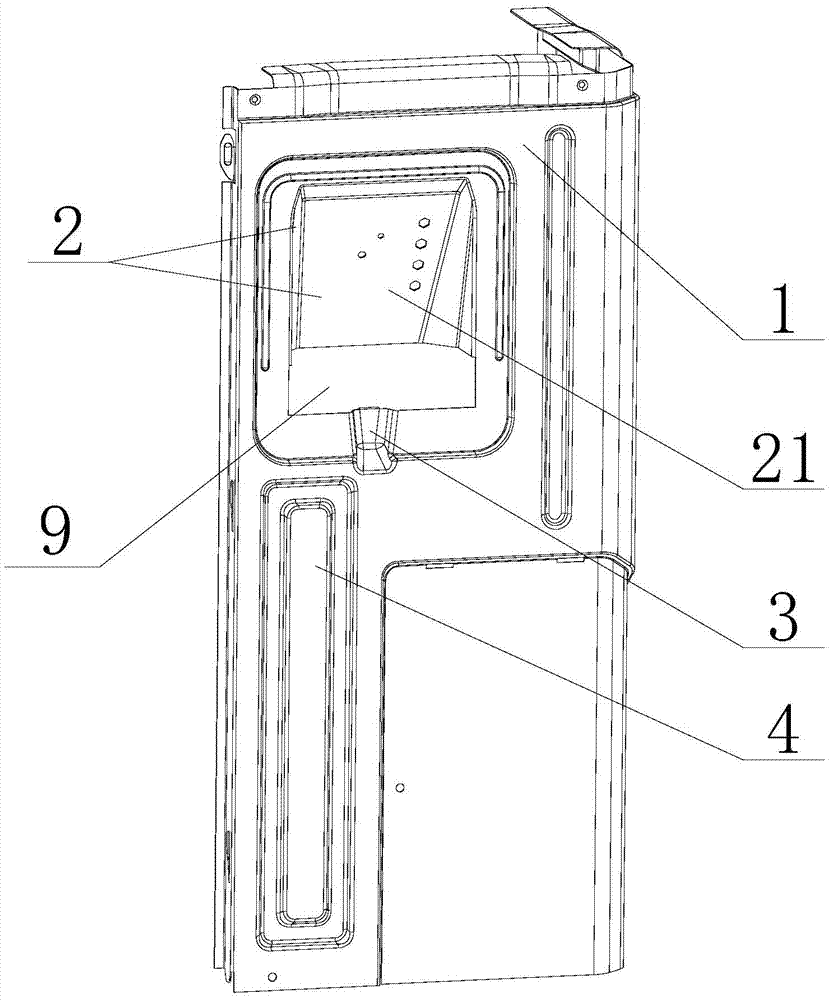

[0025] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a side panel assembly for a casing of an electrical appliance, including a side panel 1 and a wiring bracket 2 connected to the side panel 1, and the wiring bracket 2 includes a main body for installing wiring lines plate 21, the main body plate extends downward from the connection between the main body plate 21 and the upper end of the side plate 1, the main body plate 21 protrudes away from the side plate 1 and protrudes toward the inside of the casing, the main body plate 21 A downward opening 9 is formed between the side plate 1 and the side plate 1 .

[0026] Preferably, the main board is configured as a flat plate, the main board 21 is inclined at a certain angle relative to the side board 1 , and the inclined angle can be adjusted according to actual conditions to ensure the installation of wiring lines. The size of the inclination angle determines the size of the opening between the main bo...

Embodiment 2

[0032] Such as Figure 1 to Figure 3 As shown, this embodiment provides a side plate assembly. On the basis of Embodiment 1, the upper end, left end and right end of the main body plate are all closed and connected to the side plate 1, and only the lower end of the wiring bracket is open at this time. of. In this way, a cover with a closed top is formed between the wiring bracket 2 and the side plate. When water enters between the side plate and the top cover of the casing, the cover structure formed between the wiring bracket and the side plate can prevent water from entering on the wiring lines of the main board 21.

[0033] Preferably, the wiring bracket 2 and the side plate 1 are integrally formed, so that not only the parts used for connection between the wiring bracket 2 and the side plate 1 can be omitted, but compared with the prior art, there is no connection between the wiring bracket 2 and the side plate 1. Screw fixing is required, which is beneficial to ensure t...

Embodiment 3

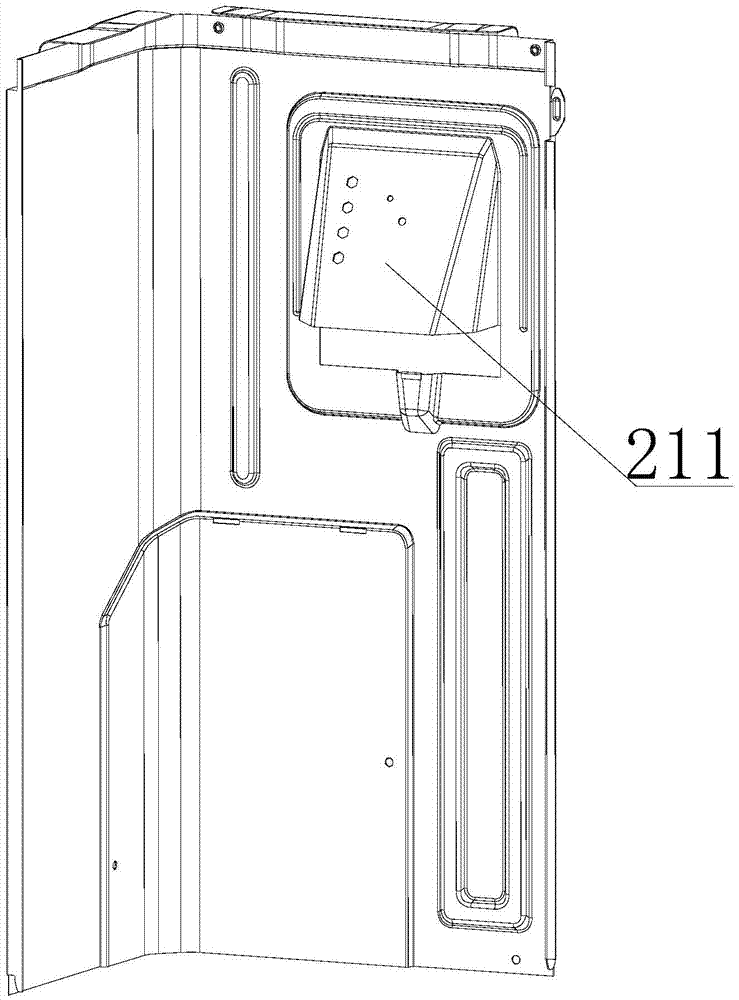

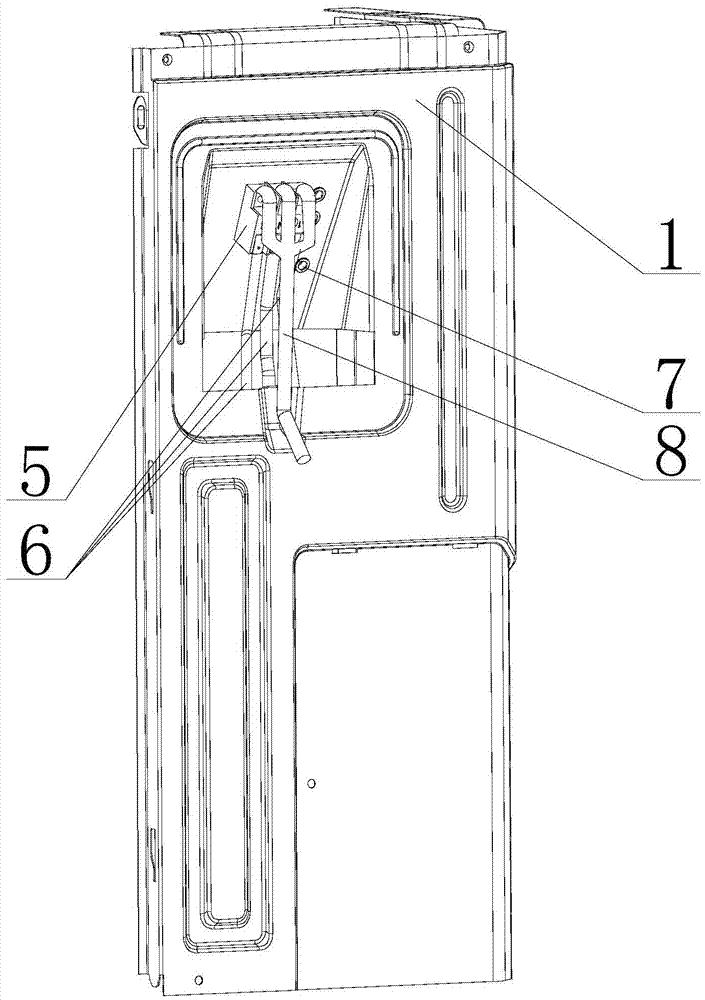

[0035] Such as Figure 1 to Figure 3 As shown, preferably, this embodiment provides a side panel assembly. On the basis of the foregoing embodiments, the wiring lines are installed on the wiring board 5 , and the wiring board is installed on the main board 21 . Preferably, the wiring board 5 is fixed on the main board through screw connection. At this time, screw connection holes are opened on the main board corresponding to the installation connection of the wiring board. In order to quickly locate and install the wiring board, a positioning hole for positioning the wiring board may also be provided on the main body board. In order to better ensure the waterproof performance of the main board 21, the connecting hole of the terminal board 5 and the main board 21 is preferably sealed, such as a sealing gasket is provided so that the water on the back side 211 of the main board 21 does not It will penetrate to the installation surface of the main board 21 .

[0036] At the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com