Bending press

A bending pressure and press technology, which is applied in the field of bending presses, can solve the problems of time-consuming equipment solutions, complex bending machines, etc., and achieve the effect of saving time and personnel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

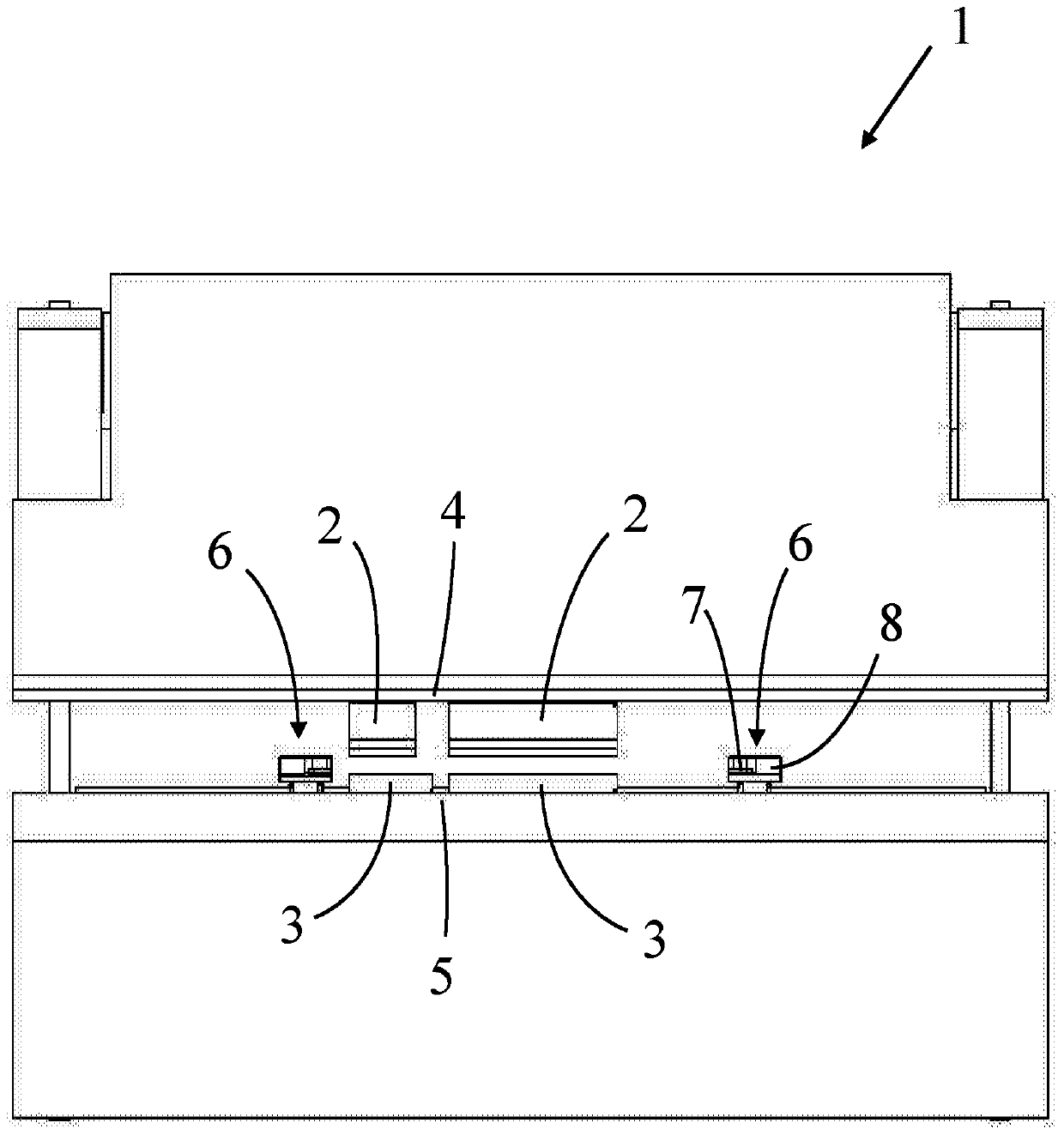

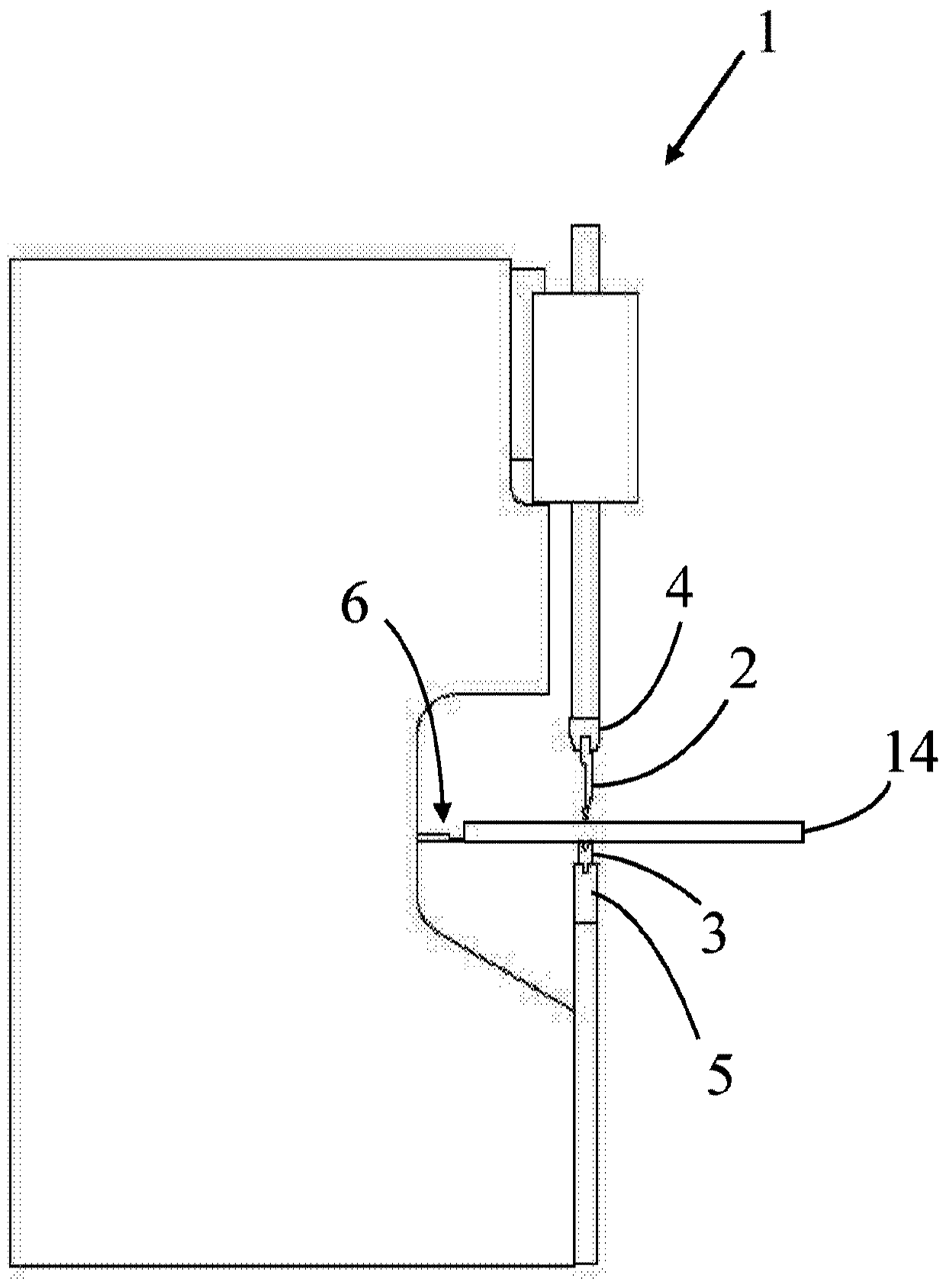

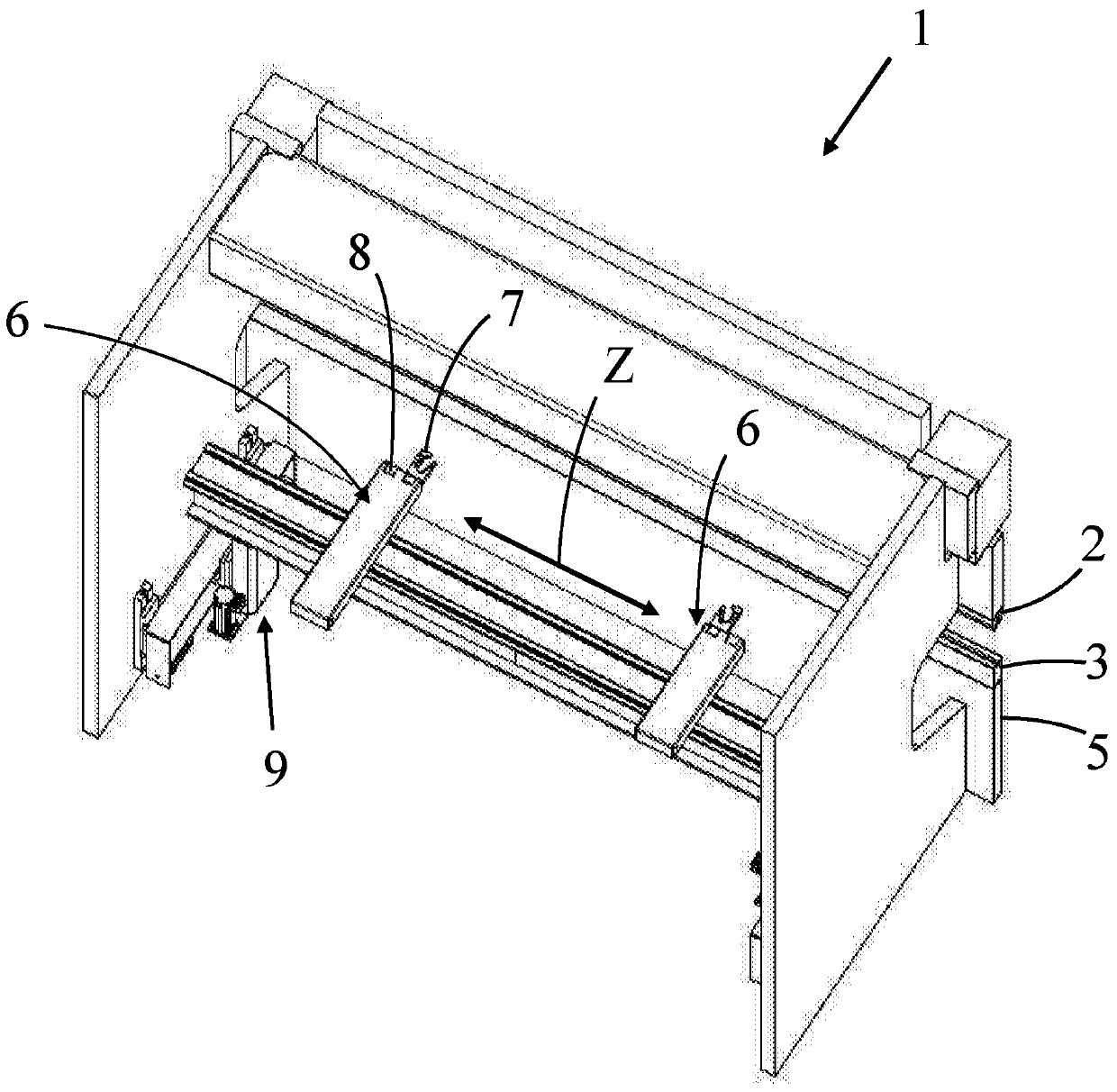

[0091] figure 1 Shown is a bending press 1 for bending workpieces with an upper tool 2 (punch) and a lower tool 3 (die), a tool holder 4 into which the upper tool 2 is inserted, and a tool holder 4 into which the lower tool 3 is inserted. Tool holder 5. The length of the tool holder 4 , 5 along the Z axis (ie parallel to the bending line) is dimensioned such that a plurality of upper and lower tools 2 , 3 can be mounted and fixed side by side in the tool holder 4 , 5 . This situation is Figure 6 is shown in , where two lower tools 3 are accommodated in a tool holder 5 .

[0092] The upper tool 2 and the lower tool 3 can be fixed in different positions within the respective tool holder 4 , 5 . This means that the tools can be arranged differently in the direction of the Z-axis relative to the corresponding tool holder.

[0093] The bending press 1 has at least one stop gauge (Anschlag) 6 for holding the workpiece 14 ( figure 2 ) is located inside the bending press 1, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com