Machine tool with rotary clamp assembly

A rotary, component technology, used in clamping, manufacturing tools, metal processing mechanical parts, etc., can solve the problem of cumbersome fixing operation, avoid manual clamping, realize automatic conversion, and reduce production and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

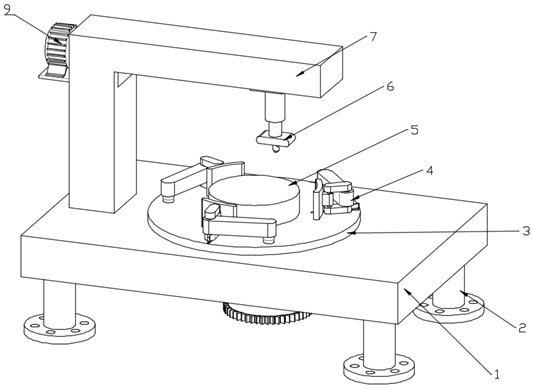

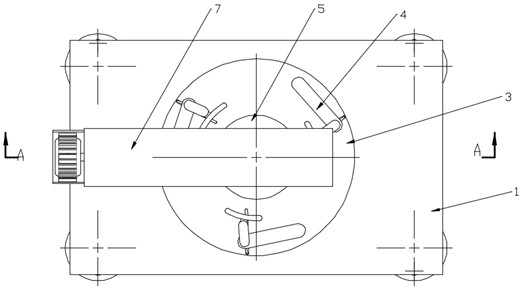

[0030] refer to Figure 1~Figure 4 In this embodiment, a machine tool with a rotary fixture assembly is proposed, which is used to clamp and rotate a workpiece 5 for processing. The machine tool with a rotary fixture assembly includes: a workbench 1, a rotating Table 3, processing assembly 6, transmission member and first motor 14.

[0031] The workbench 1 forms a support platform. The four corners of the bottom of the workbench 1 are provided with support legs 2. The bottom of the support legs 2 is fixedly connected with a backing plate. The support legs 2 support the workbench 1 to a specified height. The setting of the backing plate increases the support Stability of leg 2 support. The backing plate is provided with a through hole, and the setting of the through hole is convenient to fix the supporting leg 2 by screws, thereby fixing the machine tool.

[0032] The turntable 3 is rotatably connected to the workbench 1. The turntable 3 is a cylindrical structure, and the se...

Embodiment 2

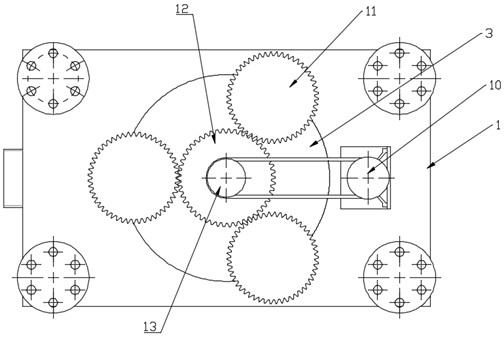

[0038] refer to Figure 5 , the clamping member 4 includes a rotating rod 20, a clamping rod 21 and a clamping plate 23, the rotating rod 20 is rotatably connected to the upper surface of the turntable 3, the rotating rod 20 is coaxially fixedly connected with the driven gear 11, and rotates The top of the rod 20 is fixedly connected to one end of the clamping rod 21, the other end of the clamping rod 21 is rotatably connected to a rotating rod 22, and one end of the rotating rod 22 is connected to a clamping plate 23, and the rotation of the rotating rod 22 drives the clamping rod 21 to rotate , so as to drive the clamping plate 23 to move to clamp the workpiece 5, thereby facilitating the fixing of the workpiece 5. One end of the rotating rod 22 is fixedly connected with a connecting rod 26, the lower end of the connecting rod 26 is connected with a protrusion, the upper surface of the rotating table 3 is provided with a guide groove, and the protrusion slides and nests insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com