Branch bending machine for Christmas tree production

A Christmas tree and bending machine technology, applied in the field of handicraft processing, can solve the problems of difficult separation and entanglement in the supporting rods, and achieve the effects of energy saving, simple structure, and convenient and fast separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

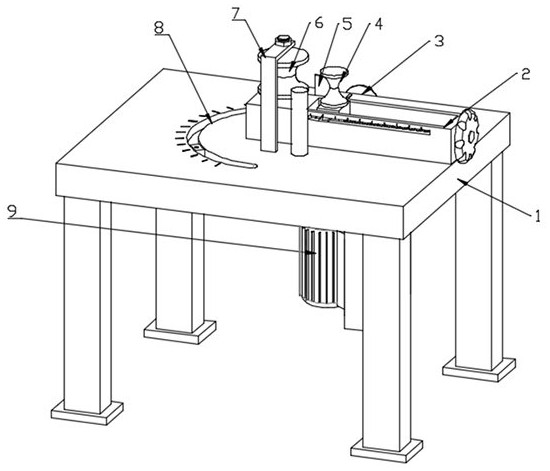

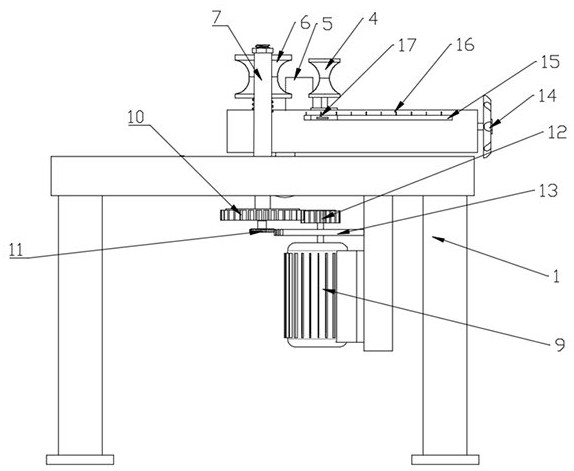

[0029] refer to Figure 1-3 In this embodiment, a branch bending machine for Christmas tree production is proposed, which is used to bend the ends of Christmas tree branches to form hooks. The branch bending machine for Christmas tree production includes: workbench 1, rotating rod 2. Clamping rod 4, supporting roller 6 and motor 9.

[0030] The workbench 1 is used to form a supporting body. The workbench 1 forms a supported horizontal platform structure, which is convenient for the bending operation. The bottom of the workbench 1 can be provided with support legs, and the workbench 1 is supported to an appropriate height by the support legs, thereby facilitating the operation.

[0031] Rotating rod 2, one end is rotatably connected on the workbench 1, the rotating rod 2 is provided with a clamping rod 4, the rotating rod 2 can be rod-shaped or square prism structure, etc., the clamping rod 4 is arranged on the side away from the rotating rod 2, The clamping rod 4 can be a cy...

Embodiment 2

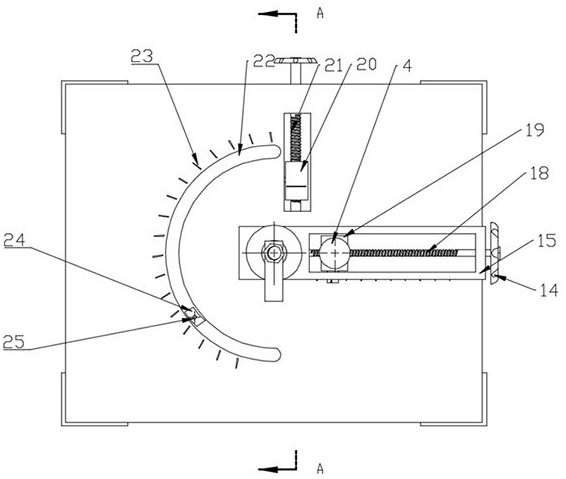

[0040] refer to Figure 4 , The workbench 1 is provided with a stopper, and the insertion depth of the end of the Christmas tree branch is adjusted through the stopper, so as to determine the bending length of the end of the Christmas tree branch. The end of the Christmas tree branch is inserted between the clamping rod 4 and the supporting roller 6 and pressed against the stop to determine the bending depth. The blocking piece is installed on the first adjusting piece 3 , and the position of the blocking piece is adjusted through the first adjusting piece 3 . The first adjusting member 3 includes a slot, a first slider 20 and a first screw 21, the first screw 21 is rotatably connected to the inside of the slot, and the inside of the slot is slidably provided with the first slider 20, The first sliding block 20 is matched and nested on the first screw rod 21 , and the blocking member is installed on the first sliding block 20 . One end of the first threaded mandrel 21 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com