Double-row angular contact ball bearing axial clearance measuring device and method

A double-row angular contact and axial clearance technology, applied in the detection field, can solve problems such as poor characterization ability, achieve strong characterization ability, improve operating efficiency, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

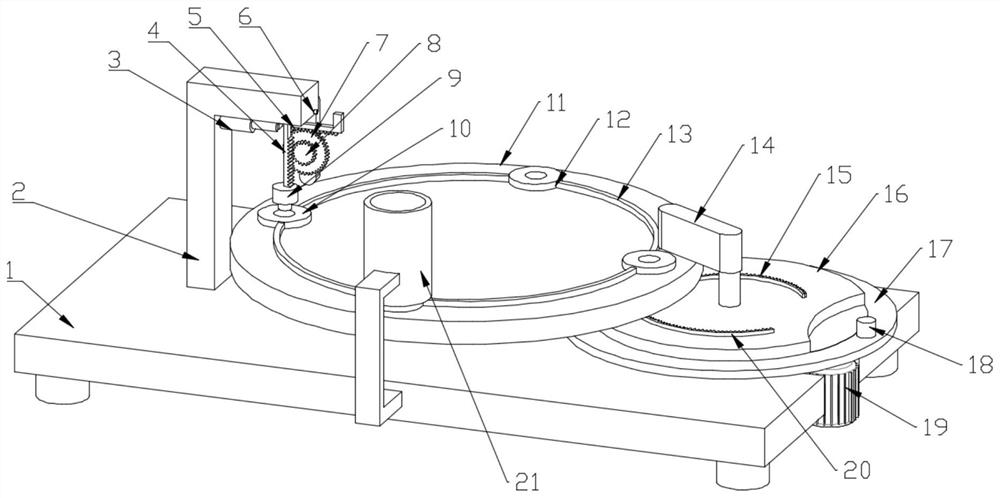

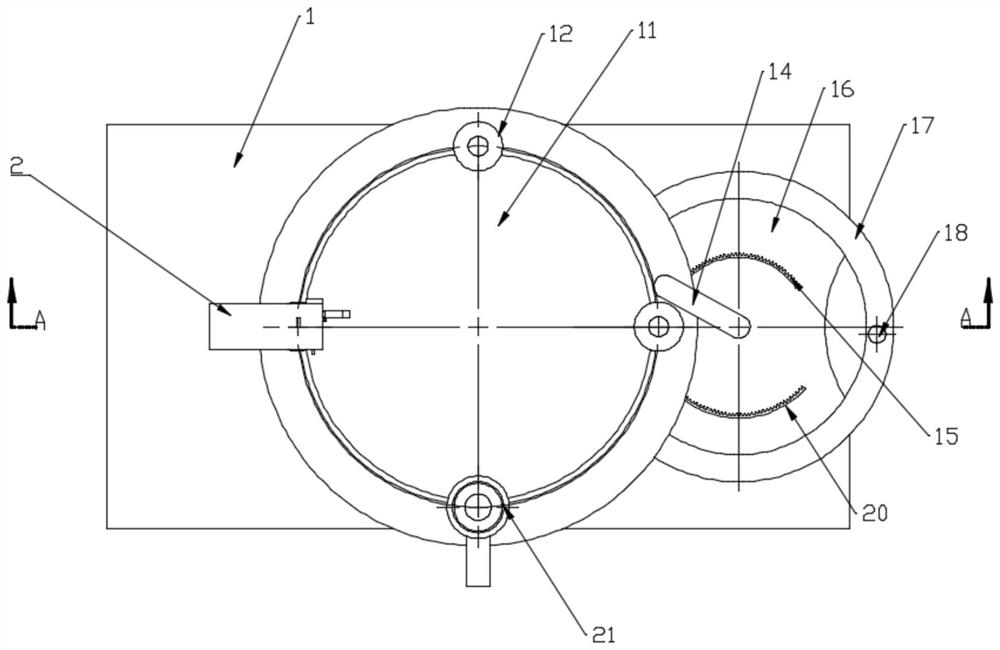

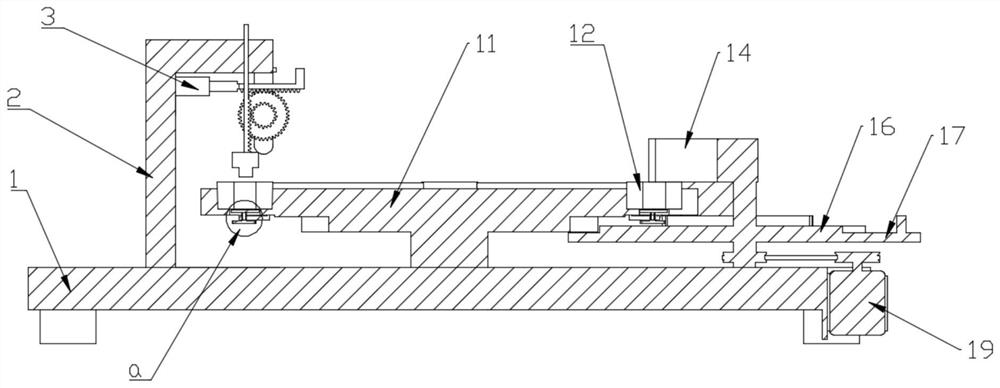

[0042] refer to Figure 1 ~ Figure 3, in this embodiment, a double-row angular contact ball bearing axial clearance measurement device is proposed, which is used to measure the axial clearance of double-row angular contact ball bearings. The double-row angular contact ball bearing shaft The device for measuring the backlash includes: a worktable 1, a working disk 11, a driving disk, a motor 19, a pressure sensor, a distance measuring sensor 6 and a controller.

[0043] The workbench 1 is used for support and installation. The workbench 1 can be a horizontal plate structure. The four corners of the bottom of the workbench 1 are provided with support legs. The bottom of the support legs can be fixedly connected with a backing plate. The support legs support the workbench 1 to the specified height. The four corners of the workbench 1 may be equipped with universal wheels, and clamping plates for braking are arranged on the universal wheels, so as to facilitate the movement and f...

Embodiment 2

[0053] refer to Figure 7 , in this embodiment, a method for measuring the axial clearance of a double row angular contact ball bearing is proposed, which includes the following steps:

[0054] S1. The bearing 10 inside the feeding barrel 21 enters the placement groove 12 of the feeding station.

[0055] S2. The rotating drive part drives the working disk 11 to rotate intermittently, and the bearing 10 enters the detection station.

[0056] S3. The telescopic driving part 3 drives the pressing part 9 to descend and press the bearing 10 .

[0057] S4. Obtain the pressure F sensed by the pressure sensor and the stroke distance L sensed by the distance measuring sensor 6 .

[0058] S5. Judging whether the travel distance L is greater than a preset L 标 , if yes, execute S6.

[0059] S6. Sending a first alarm signal.

[0060] S7, judging whether L / (F-G) is greater than a preset θ 标 , if yes, execute S8.

[0061] S8. Sending a second alarm signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com