Terahertz wave fiber wave guide

A fiber waveguide and terahertz technology, which is applied in the field of terahertz fiber waveguides, can solve the problems that it is difficult to meet the needs of terahertz beam interference applications, and does not consider the polarization-maintaining requirements of transmitting terahertz beams, and achieves the difference between the equivalent refractive indices. High, strong restraint ability, the effect of reducing transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

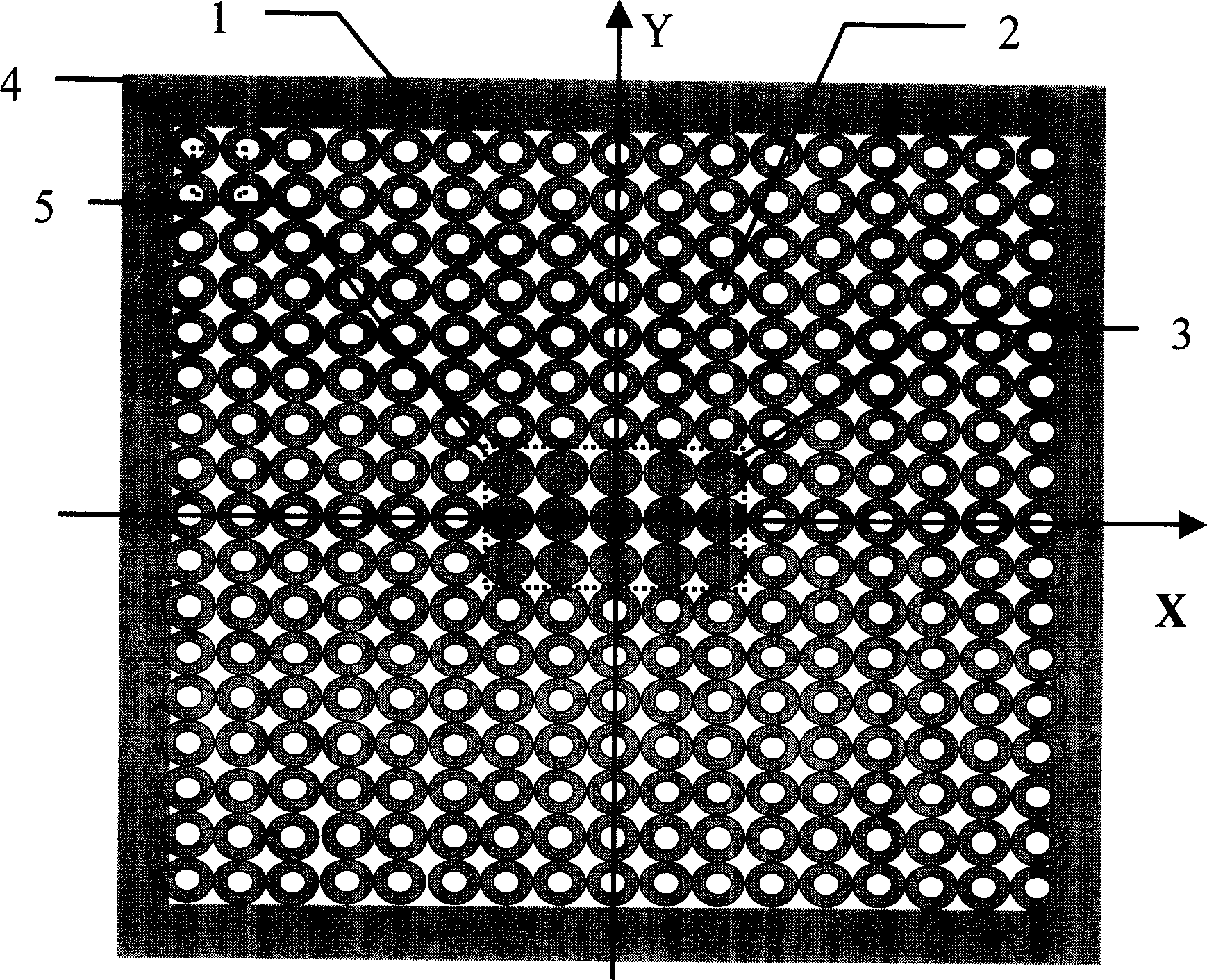

[0021] Example 1: Polarization-maintaining terahertz wave fiber waveguide with square lattice structure cladding area and rectangular core area, the cross-sectional structure is as follows figure 1 shown.

[0022] The material of the capillary cylinder 3, the capillary tube 2 and the outer casing 1 of the fiber waveguide is uniform high-density polyethylene. The outer radius of the capillary cylinder 3 and the capillary tube 2 are both 0.37mm, the inner radius of the capillary tube 2 is 0.12mm, and the inside and outside have the same column center. The cross section of the outer sleeve 1 of the fiber waveguide is square, with a uniform wall thickness of 0.35mm and a hollow dimension of 12.6mm×12.6mm.

[0023] In the outer sleeve 1 of the fiber waveguide, 17×17 capillary tubes 2 are periodically arranged in parallel to the axial direction, and every 4 adjacent capillary tubes 2 in the cross section are connected to form a uniform regular square grid network Grid 4.

[0024]...

Embodiment 2

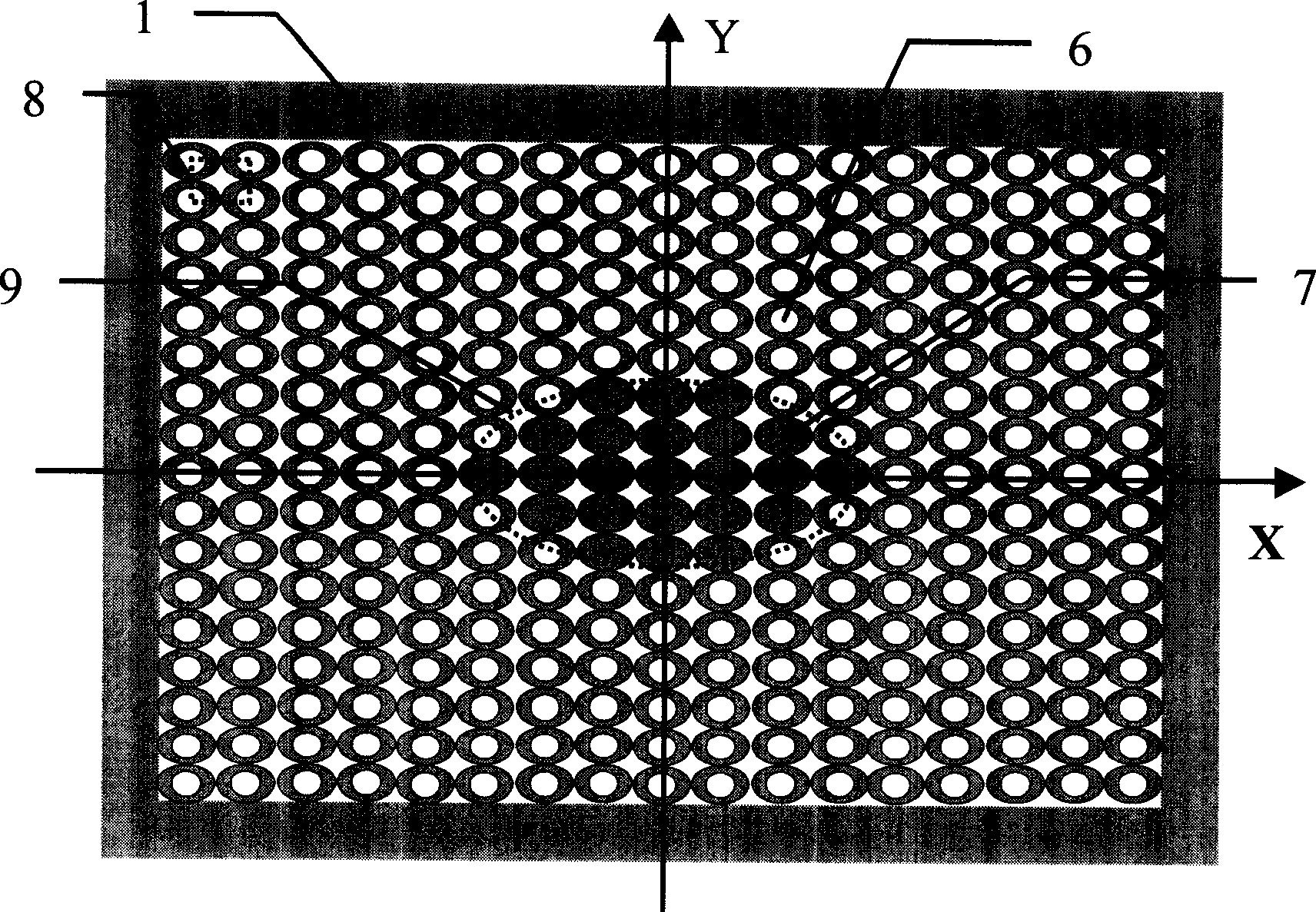

[0027]Example 2: A cladding region with a rectangular lattice structure and a polarization-maintaining terahertz wave fiber waveguide with an elliptical core region, the cross-sectional structure is as follows image 3 shown.

[0028] The material of the capillary elliptical cylinder 7, the capillary 6 with an elliptical cylindrical outer shape and the inner cylindrical shape and the outer tube 1 of the fiber waveguide is uniform polytetrafluoroethylene. The capillary ellipse 7 and the outer ellipse cylindrical inner capillary 6 have a major axis radius of 0.37mm and a minor axis radius of 0.29mm, and the outer elliptical cylindrical inner radius of the cylindrical capillary 6 is 0.12mm, the same column center inside and outside. The cross-section of the outer sleeve 1 of the fiber waveguide is rectangular, with a uniform wall thickness of 0.35 mm and a hollow dimension of 12.6 mm×9.9 mm.

[0029] In the outer sleeve 1 of the fiber waveguide, 17×17 capillaries 6 with an elli...

Embodiment 3

[0033] Example 3: A cladding region with a rectangular lattice structure and a long X-shaped core region polarization-maintaining terahertz wave fiber waveguide, the cross-sectional structure is as follows Figure 5 shown.

[0034] The capillary elliptical cylinder 7, the inner and outer elliptical cylindrical capillary 10 and the outer tube 1 of the fiber waveguide are made of uniform polycarbonate. The capillary ellipse cylinder 7 and the inner and outer ellipse cylindrical capillary tubes 10 have a major axis radius of 0.37 mm and a minor axis radius of 0.29 mm, while the inner and outer ellipse cylindrical capillary tubes 10 have an ellipse major axis radius of 0.15 mm and a minor axis radius of 0.15 mm. It is 0.11mm, and the inside and outside have the same column center. The outer sleeve 1 of the fiber waveguide has a rectangular cross section with a uniform wall thickness of 0.35mm and a hollow dimension of 12.6mm×14mm.

[0035] In the outer sleeve 1 of the fiber wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com