Shaping mould cup with built-in elastomers and manufacturing method of shaping mould cup

An elastic body, mold cup technology, applied in clothing, bras, bras and other directions, can solve the problems of tight fabrics, plump women and summer bras, lack of choice, limited gathering and shaping effects, etc., to achieve good support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

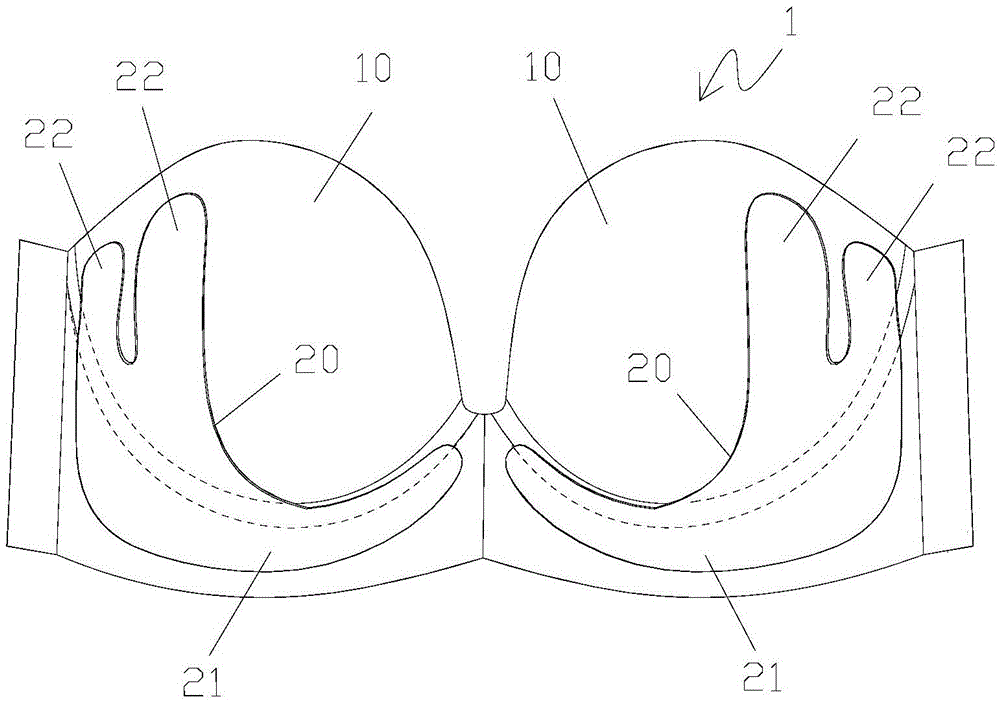

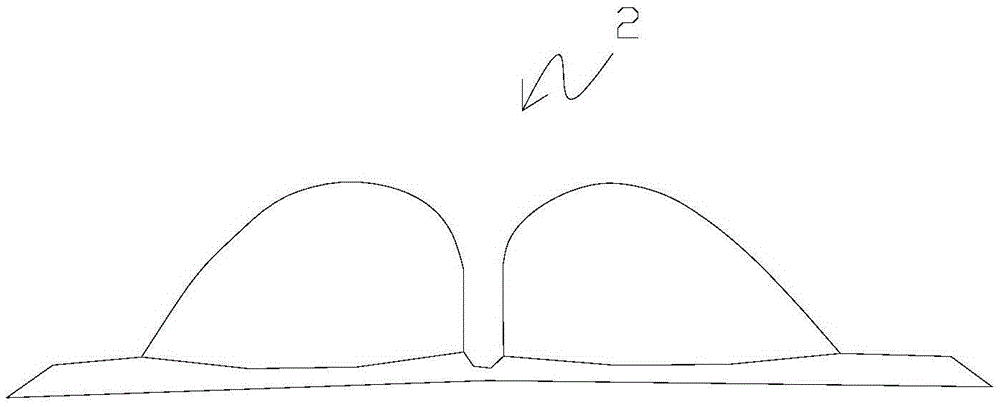

[0027] see figure 1 and 2 , a kind of molding mold cup with built-in elastic body of the present embodiment, comprises the mold cup body 1 obtained by pressing the upper layer cotton and the lower layer cotton, the left and right sides of the mold cup body 1 respectively have a bowl-shaped cup body 10, each bowl A sheet-shaped elastic body 20 for support is built in the cup body 10, and the elastic body 20 is sandwiched between the upper layer of cotton and the lower layer of cotton.

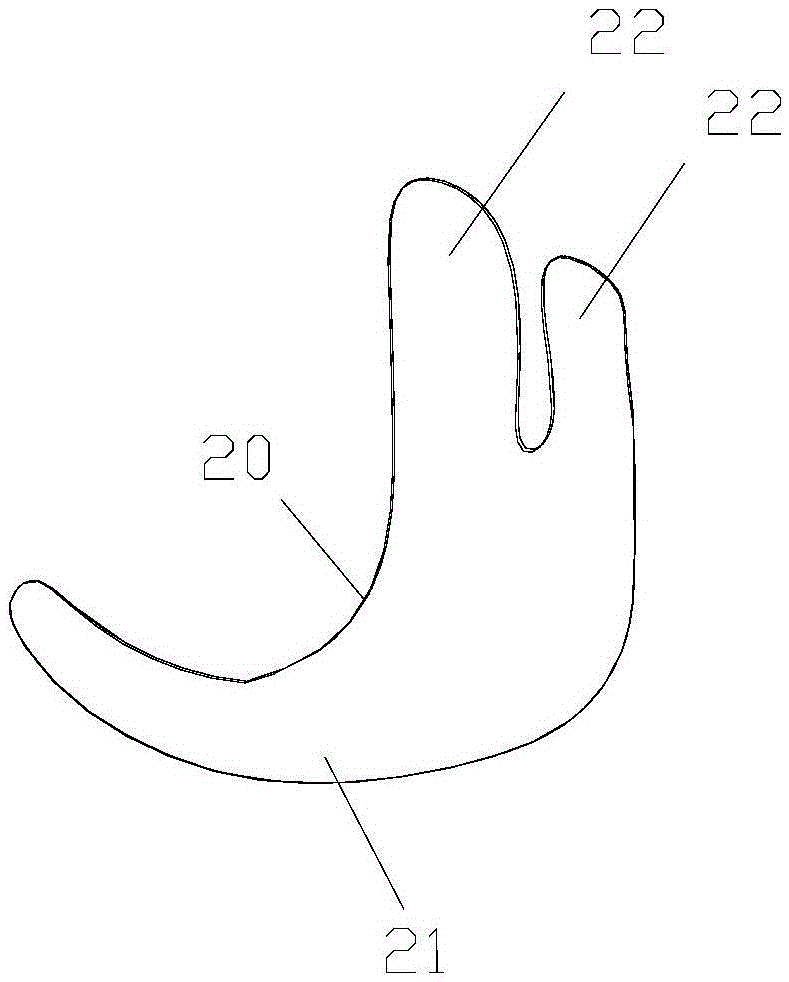

[0028] Such as figure 2 As shown, each elastic body 20 has an arc-shaped base portion 21 corresponding to the lower circumference of the bowl-shaped cup body 10 , and the arc-shaped base portion 21 extends from the outer side of the bowl-shaped cup body 10 to the inner side. A position near the outer side of each elastic body 20 also has a side extending branch 22 extending upward along the bowl-shaped cup body 10 . The extended branch 22 is combined with the arc-shaped base 21 to form a tig...

Embodiment 2

[0032] see Figure 5 , a kind of plastic mold cup with built-in elastic body of the present embodiment, comprises the mold cup body 3 obtained by pressing the upper layer cotton and the lower layer cotton, the left and right sides of the mold cup body 3 respectively have a bowl-shaped cup body 30, each bowl A sheet-shaped elastic body for support is built in the cup body 30, and the elastic body is sandwiched between the upper layer of cotton and the lower layer of cotton. The elastic bodies in the left and right bowl-shaped cups 30 of the mold cup body 3 are connected at the heart of the mold cup body 3 to form a "W" type integrated elastic body 40 . The "W"-shaped integrated elastic body 40 makes the left and right bowl-shaped cups 30 form a unified integrated bra, which can simultaneously support the left and right breasts and avoid the difference in height between the left and right breasts. In this embodiment, the "W" shaped one-piece elastic body 40 has a concave groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com