Method for measuring liquid level fluctuation of crystallizer and flow field symmetry

A technology of liquid level fluctuation and crystallizer, which is applied in the field of iron and steel metallurgy and steelmaking, can solve the problems of inability to obtain the liquid level profile, inability to study the liquid level fluctuation, and increase of the defect rate of the cast slab.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

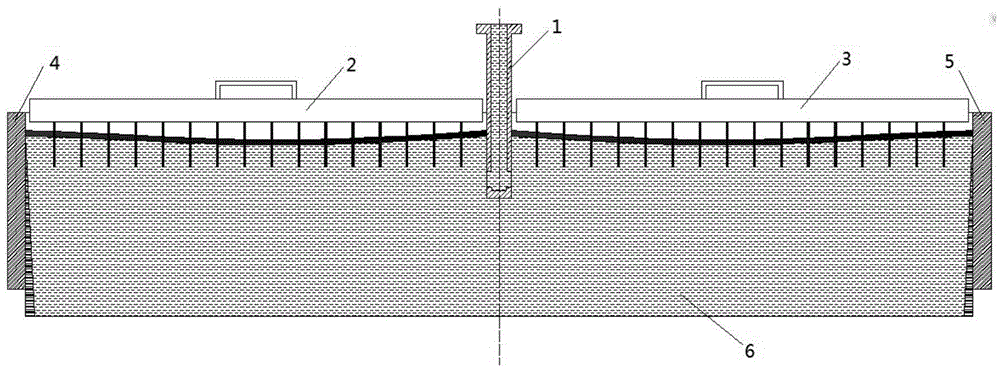

[0049] It is carried out on a continuous casting machine with a crystallizer section size of 200mm×1500mm and a nozzle outer diameter of 80mm, including the following steps:

[0050] (1) Making steel nail plate:

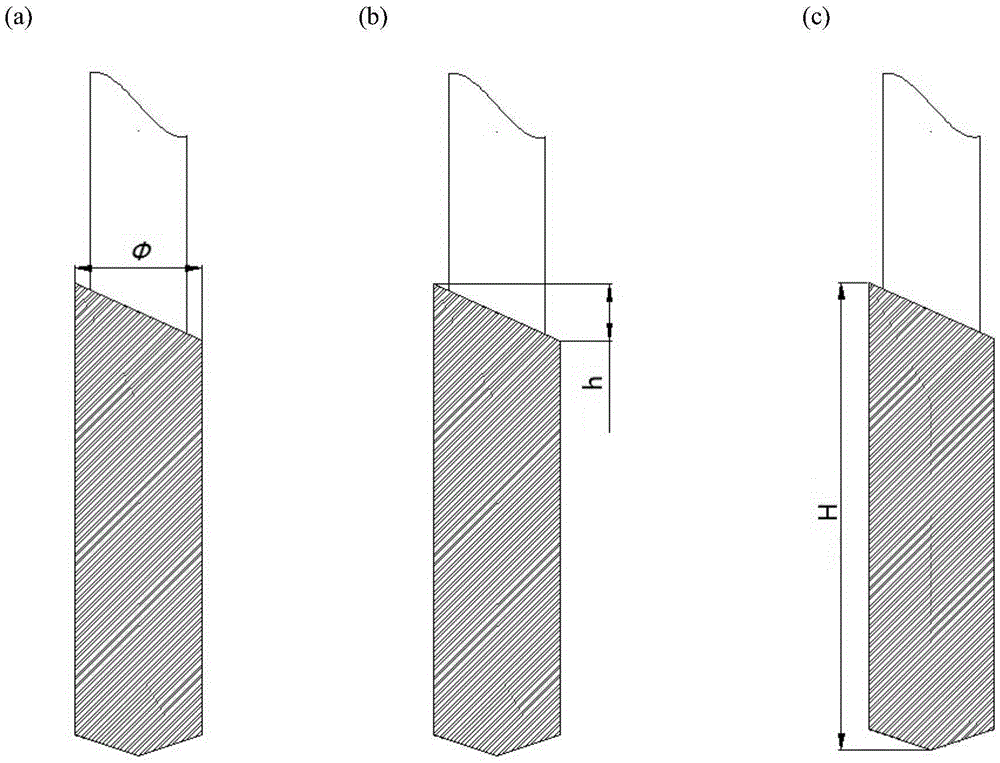

[0051] The steel nails are 150mm in length and 10mm in diameter, and are evenly distributed in 3 rows x 11 columns on a wooden board with a thickness of 90mm, of which the length of the wooden board is 710mm and the width is 190mm;

[0052] (2) mark the position of the nozzle, the position of the narrow face and the position of the inner and outer arcs on the steel nail plate described in step (1);

[0053] (3) In the actual pouring process, insert the marked steel nail plate described in step (2) vertically into the crystallizer liquid surface at the same time on both sides of the nozzle according to the marked position, and lift it out vertically at the same time after 2 seconds, and wait for it to cool;

[0054] (4) Repeat step (3) every 8 minutes for a total of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com