Gearbox, power transmission system and vehicle

A power transmission system and transmission technology, applied in the direction of power devices, vehicle parts, air pressure power devices, etc., can solve the problems of fewer transmission paths, fewer and single transmission modes of the power transmission system, and achieve the effect of enriching transmission modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

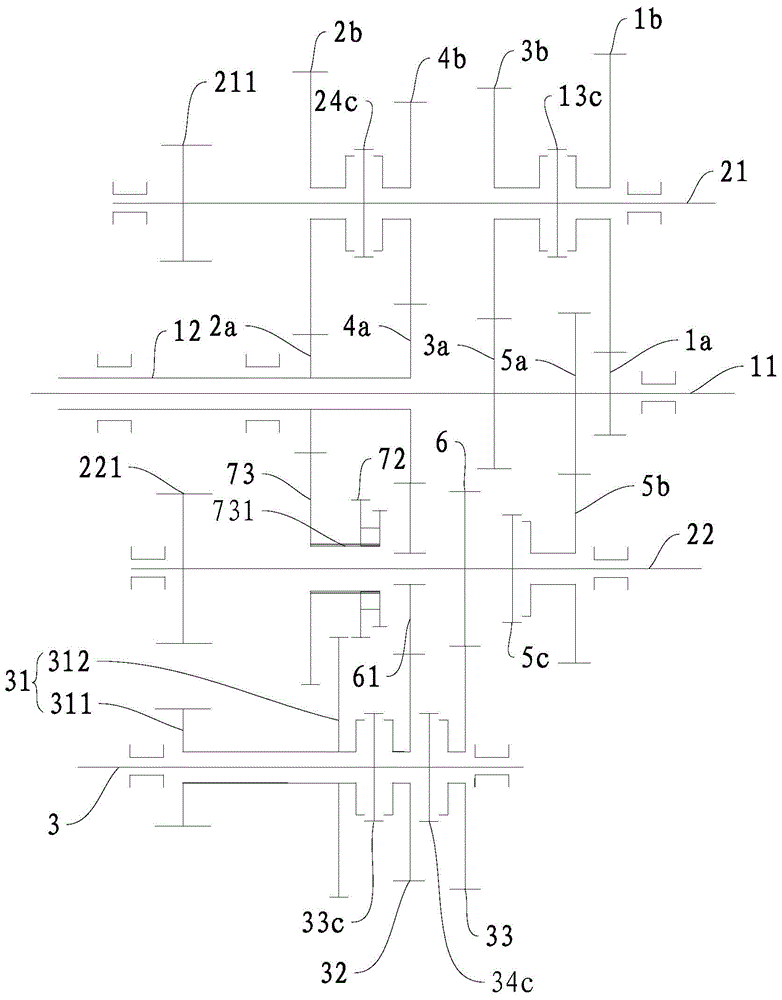

Image

Examples

Embodiment 1

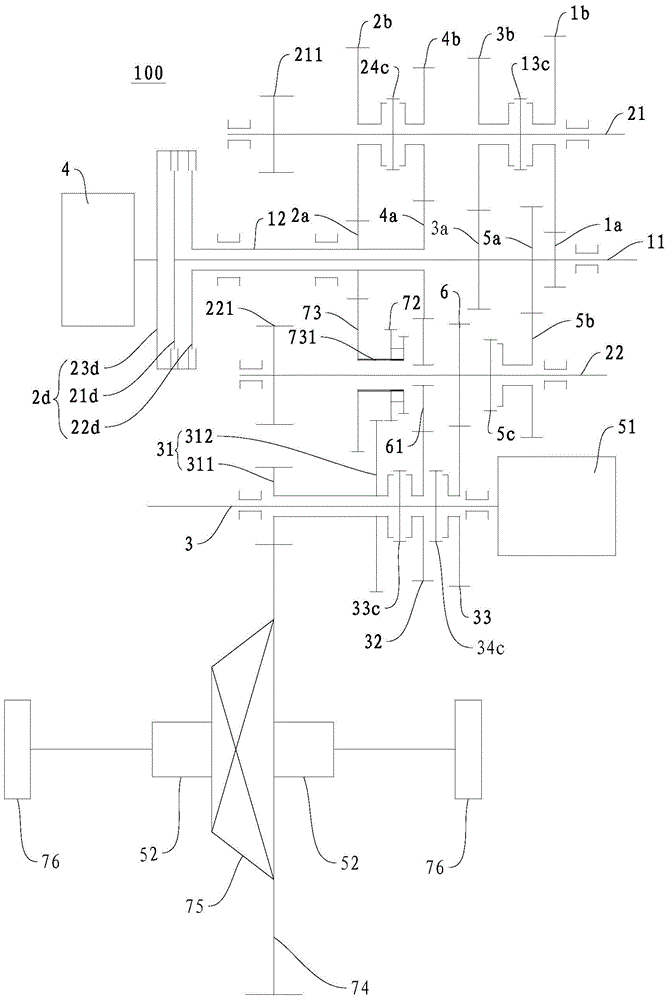

[0144] Such as figure 2 As shown, the engine 4 is connected with the input end 23d of the double clutch 2d, the first output end 21d of the double clutch 2d is connected with the first input shaft 11, the second output end 22d of the double clutch 2d is connected with the second input shaft 12, and the double clutch 2d is connected with the second input shaft 12. The input end 23d of the clutch 2d and the first output end 21d and the second output end 22d of the double clutch 2d can be in disconnected state at the same time, or the input end 23d of the double clutch 2d can be connected with the first output end 21d and the second output end 21d of the double clutch 2d. One of the two output terminals 22d is engaged, or the input terminal 23d of the dual clutch 2d can be simultaneously engaged with the first output terminal 21d and the second output terminal 22d of the dual clutch 2d.

[0145] The second input shaft 12 is a hollow shaft structure, the first input shaft 11 is...

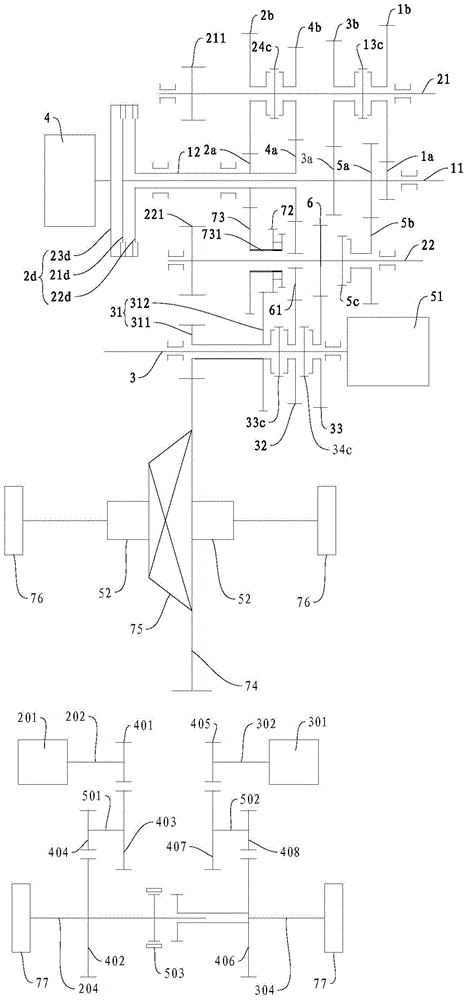

Embodiment 2 Embodiment 5

[0205] Such as image 3 - Figure 6 As shown, the power transmission system 100 and figure 2 The main difference of the power transmission system 100 shown in FIG. The description of the structure will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com