Groove-type rail for logistics trolley

A trolley track and logistics technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of deviation of walking direction and poor accuracy, and achieve the effect of good guiding effect, long service life and smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

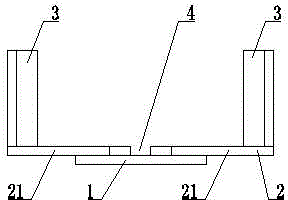

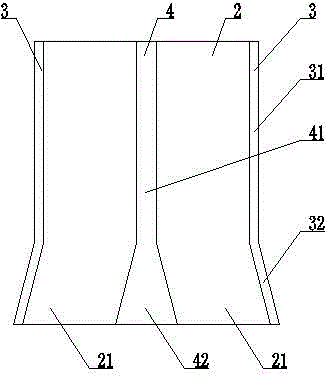

[0008] see Figure 1 to Figure 2 , the present invention includes a bottom plate 2, also includes a connecting plate 1 and two side plates 3 symmetrically welded on the left and right sides of the bottom plate 2, the side plates 3 include a walking plate 31 and a guide plate 32, and the bottom plate 2 is composed of two It consists of slanted plates 21 symmetrically welded on the upper surface of the connecting plate 1 , and a guide groove 4 is provided between the two slanted plates 21 , and the guide groove 4 includes a walking guide groove 41 and a guiding guide groove 42 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap