An embedded track structure with convenient maintenance

An embedded track, convenient technology, applied to the upper structure of the track, track, road, etc., can solve the problems of difficult readjustment of the rail, and achieve the effect of convenient maintenance and free adjustment of elevation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

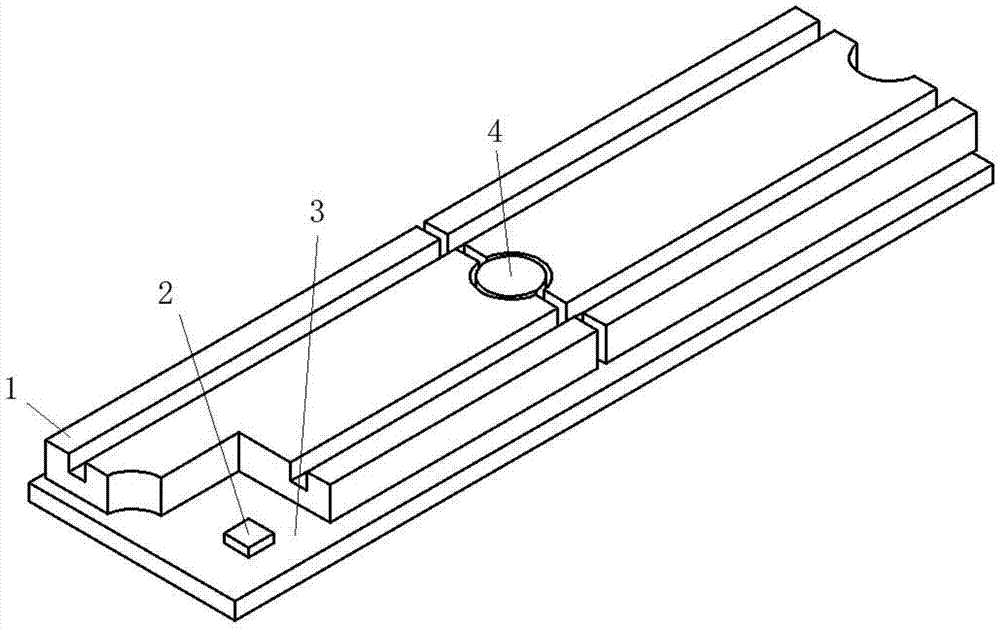

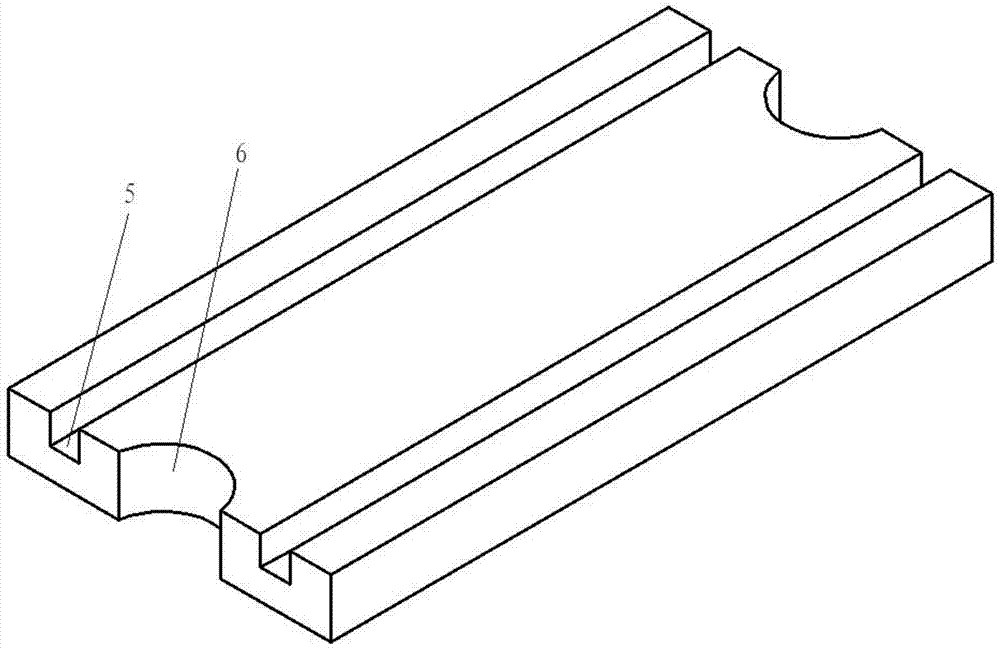

[0037] figure 1 shows a schematic structural view of an embedded track structure that is easy to maintain in Example 1, image 3 A schematic structural view of the prefabricated track slab in this example is shown.

[0038] Such as figure 1As shown, the maintenance-friendly embedded track structure in this example includes a track slab base 3 and a prefabricated track slab 1 disposed on the track slab base 3 , a track slab adjustable support 2 and a track slab limiting boss 4 . Such as image 3 As shown, the prefabricated track slab 1 has two rail bearing grooves 5 arranged on the top surface, and the two rail bearing grooves are symmetrically arranged in the transverse direction and extend longitudinally. Circular semi-accommodating groove 6. The track slab adjustable support 2 is arranged between the prefabricated track slab 1 and the track slab base 3, is located at the four corners of the prefabricated track slab 1 and supports the prefabricated track slab 1, and the t...

example 2

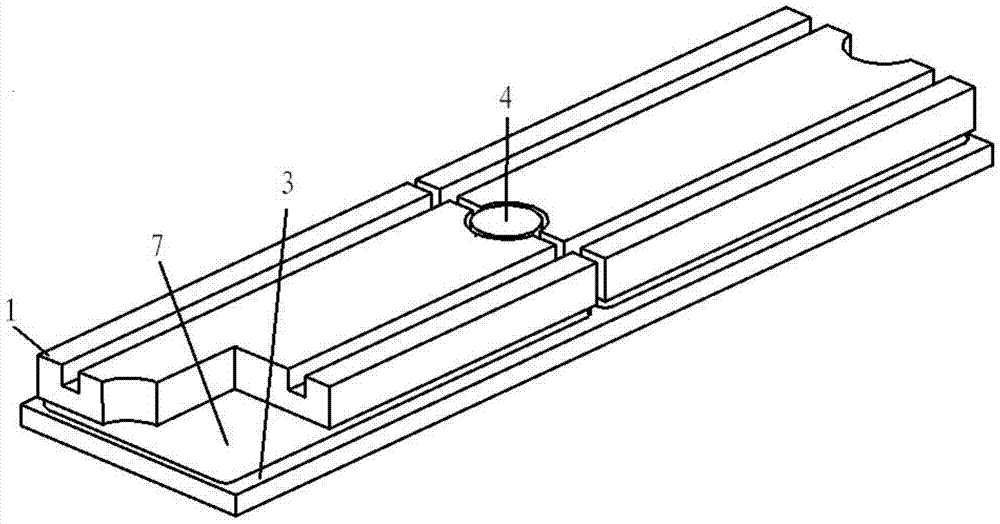

[0040] figure 2 shows the structural schematic diagram of the convenient maintenance embedded track structure in Example 2, image 3 A schematic structural view of the prefabricated track slab in this example is shown.

[0041] Such as figure 2 As shown, the maintenance-friendly embedded track structure in this example includes a track slab base 3 and a prefabricated track slab 1 , a CA mortar layer 7 and a track slab limiting boss 4 arranged on the track slab base 3 . Such as image 3 As shown, the prefabricated track slab 1 has two rail bearing grooves 5 arranged on the top surface, and the two rail bearing grooves are symmetrically arranged in the transverse direction and extend longitudinally. Circular semi-accommodating groove 6. The CA mortar layer 7 is arranged on the entire contact surface between the prefabricated track slab 1 and the track slab base 3 and supports the prefabricated track slab 1. The CA mortar layer 7 is constructed with a pouring bag and can re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com