Air intake system for an engine

An engine system, air intake system technology, applied to engine components, combustion engines, machines/engines, etc., that can solve problems such as increased cost, difficult intake system and engine assembly, difficult access to maintenance or repair air handling components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

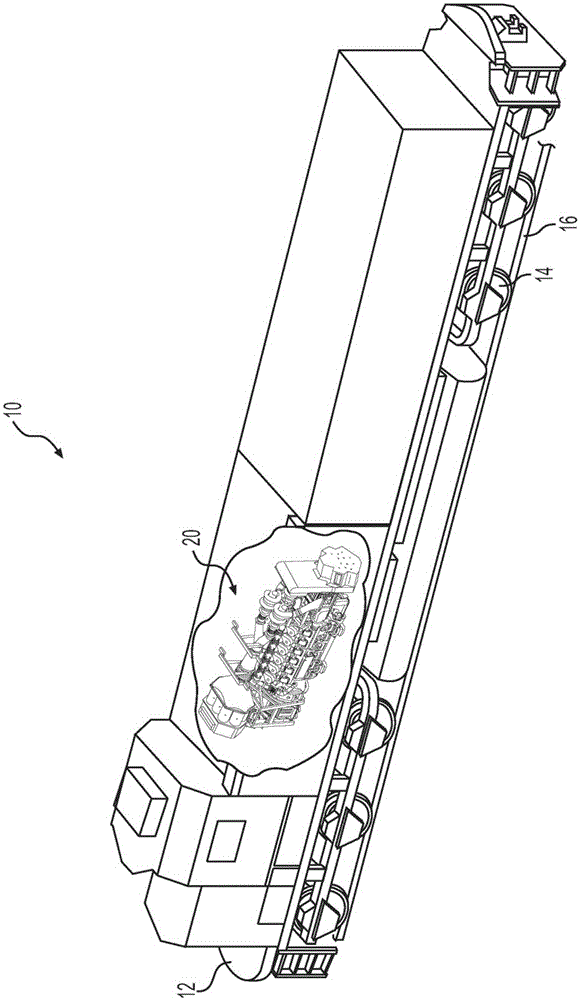

[0013] figure 1 An exemplary embodiment of machine 10 is shown. Machine 10 may be a machine that performs some type of work related to an industry such as railroading, marine, power generation, mining, construction, agriculture, or another industry known in the art. For example, if figure 1 As shown, machine 10 may be a locomotive designed to haul railroad vehicles. Machine 10 may have a platform 12 supported by a plurality of wheels 14 that may be configured to engage rails 16 . Wheels 14 may have traction motors (not shown) associated therewith that may drive wheels 14 to propel machine 10 in a forward or rearward direction.

[0014] Machine 10 may have engine system 20 mounted on platform 12 . In an exemplary embodiment, as figure 1 As shown, engine system 20 may be arranged longitudinally on platform 12 in the direction of travel of machine 10 . However, those skilled in the art will recognize that engine system 20 may be arranged on platform 12 front-to-back, latera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com