Novel bus duct tapping device

A busway, a new type of technology, applied in the direction of open busway installation, riveting connection, etc., can solve the problem of reducing the contact resistance and temperature rise of the connection at the two ends of the busway and the plugging point of the branch line, the reduction of the rated operating current, Reduced safety protection performance and other issues, to achieve the effect of convenient and normal power supply, reliable contact, and high safety protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

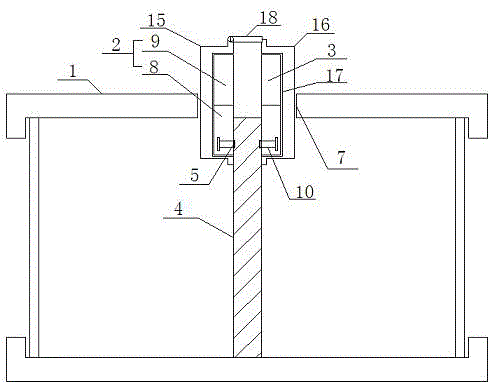

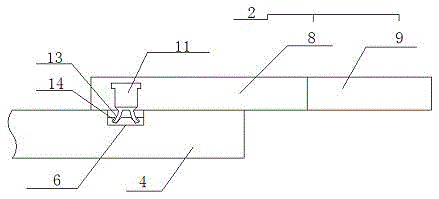

[0020] The embodiment of the substrate of the present invention will be further described below in conjunction with the accompanying drawings.

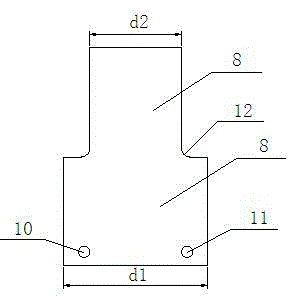

[0021] A new type of bus duct tapping device, comprising a bus duct housing 1, a first connecting copper bar 2 and a second connecting copper bar 3, wherein, the bus duct housing 1 is provided with a main bus bar 4, and the main bus bar 4 Both sides of the busbar 4 are respectively provided with a first installation groove 5 and a second installation groove 6, the busbar housing 1 is provided with an opening 7, the opening 7 is located on the side of the main busbar 4, the first connection Both the copper bar 2 and the second connecting copper bar 3 are composed of a primary plate 8 and a secondary plate 9, the primary plate 8 and the secondary plate 9 are rectangular structures, the width of the primary plate 8 is d1, The width of the secondary plate 9 is d2, the d1:d2=1.3:1;

[0022] One side of the primary plate 8 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com