Flame retardant film

A flame retardant film and film technology, applied in the field of flame retardant film, can solve problems such as heavy smoke, flame retardant compound health and environmental elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

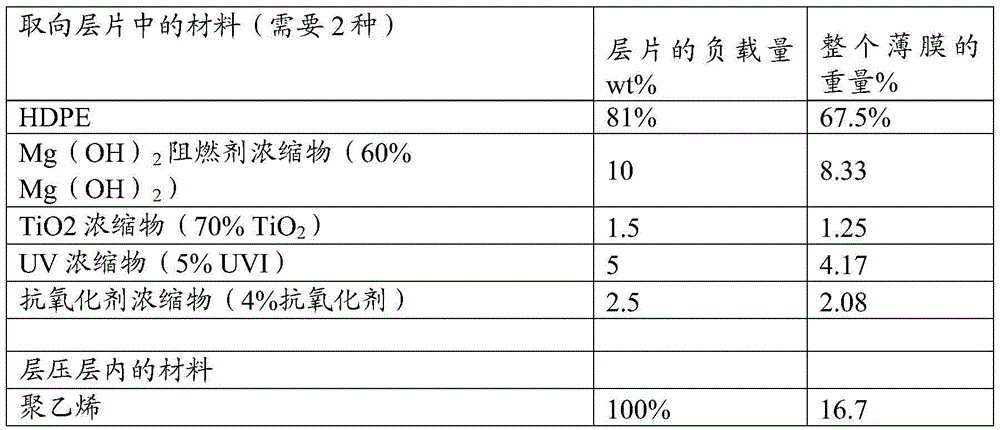

[0015] The present disclosure allows embodiments in various forms, and one or more embodiments are shown in the drawings and will be described below as follows, the present disclosure is to be considered as illustrative only and is not intended to The disclosure is limited to any particular embodiment described or illustrated.

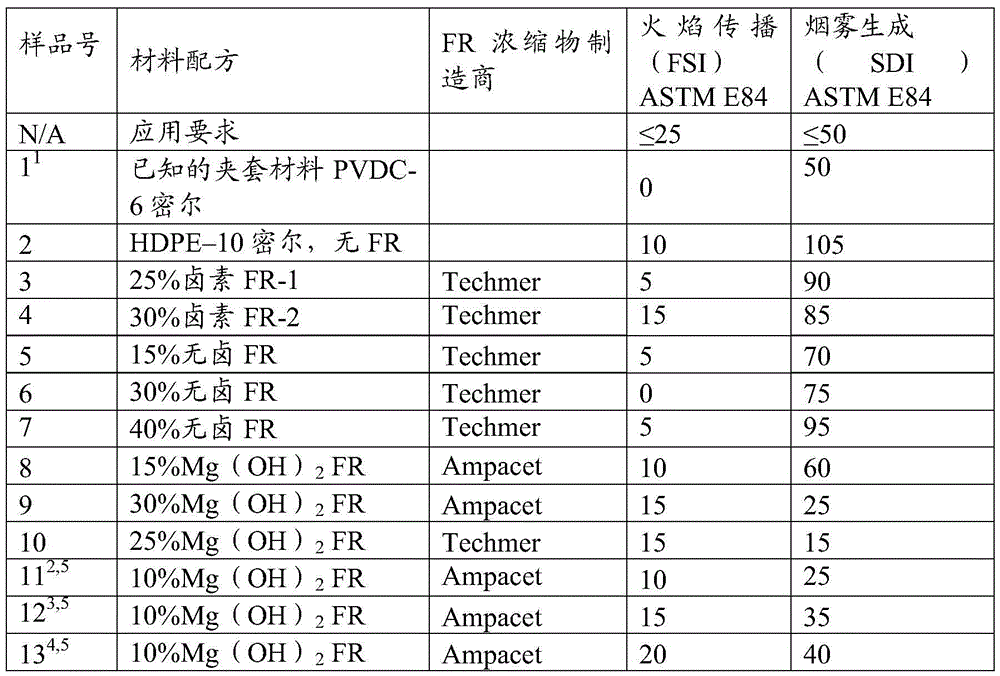

[0016] Polyolefin films are made to meet the requirements of a flame spread index of less than 25 and a smoke formation index of less than 50. In an embodiment, the film is a thin film having a thickness of about 0.003 to 0.010 inches. One film can be made from high density polyethylene (HDPE). In an embodiment, magnesium hydroxide is used to reduce smoke generation without adversely affecting flame spread.

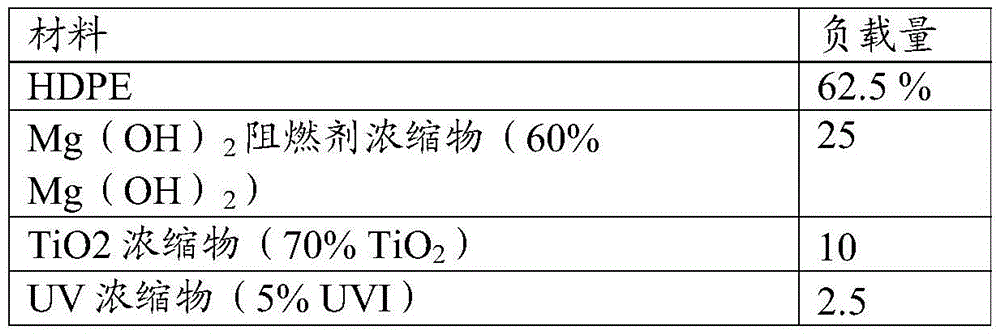

[0017] Table 1 below presents an example of a formulation for a 10 mil film that results in a Flame Spread Index of 15 and a Smoke Formation Index of 15. The film is shown as sample number 10 in Table 3 below.

[0018]

[0019] Table 1 - Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap