Feeder

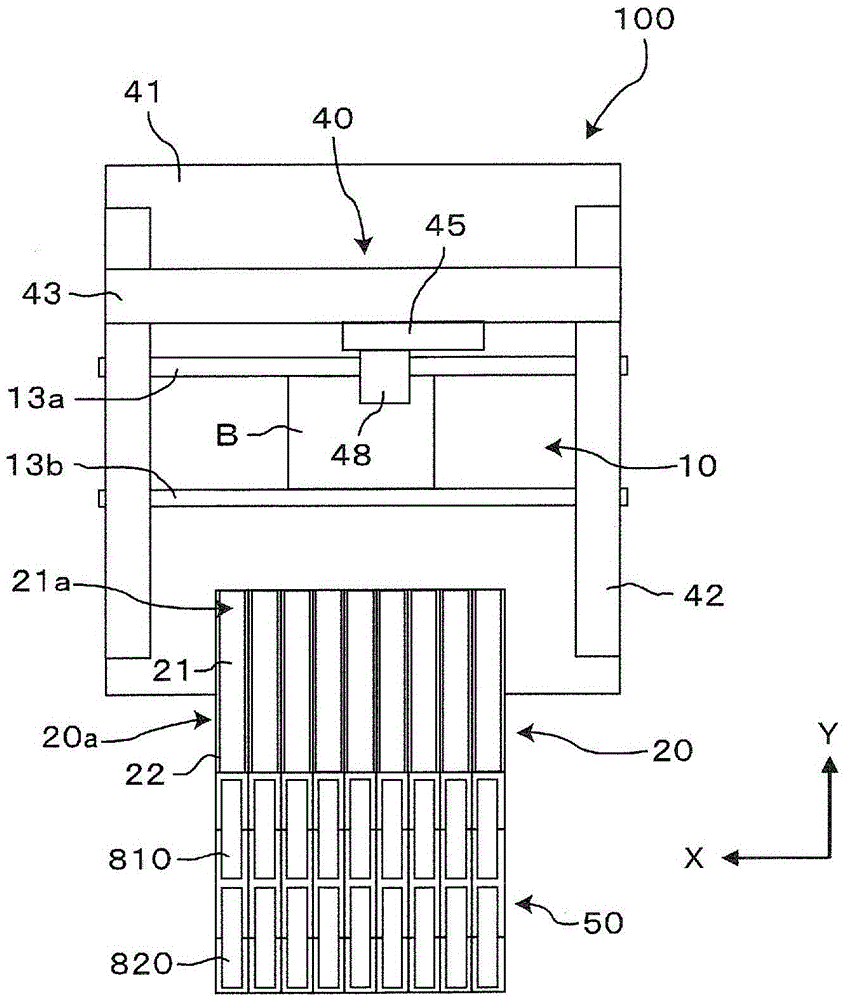

A feeder, carrier tape technology, applied in thin material processing, coiling strips, electrical components, etc., can solve problems such as supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

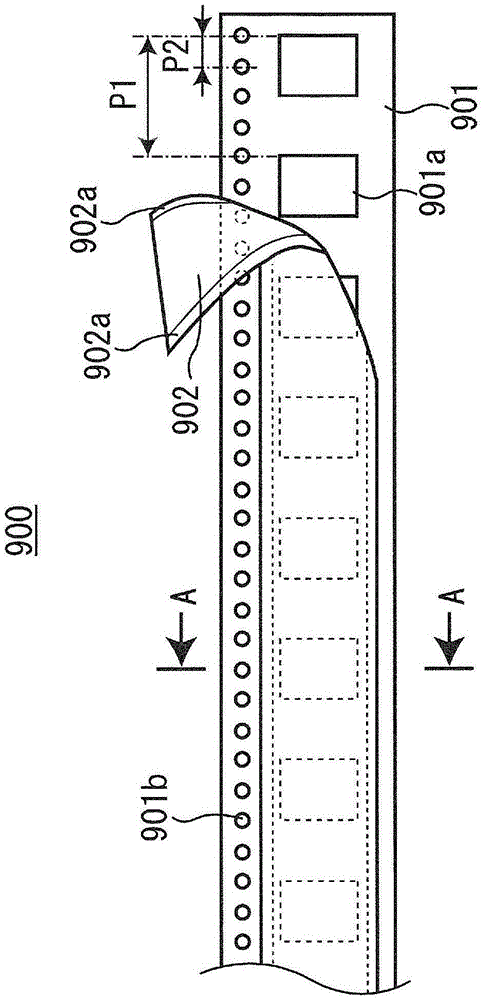

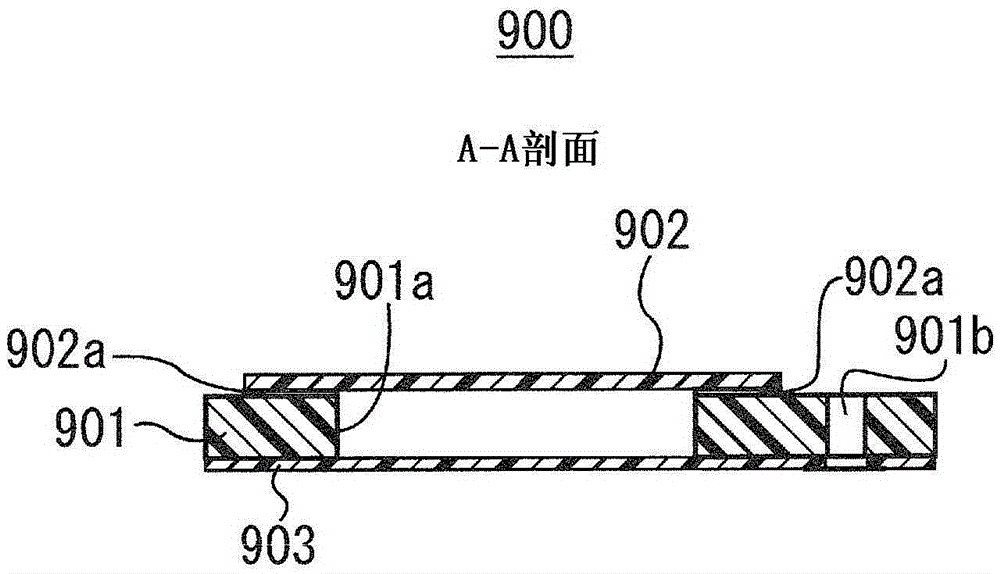

[0096] In the above-described embodiment, such as Figure 7 , Figure 8 As shown, by setting the tooth thickness dimension b of the second engaging protrusion 62a to be smaller than the tooth thickness dimension a of the first engaging protrusion 61a, the cross-sectional area of the second engaging protrusion 62a is set to be larger than that of the first engaging protrusion. The cross-sectional area of the engagement protrusion 61a is small. However, even by setting the tooth width dimension d of the second engaging protrusion 62a to be smaller than the tooth width dimension c of the first engaging protrusion 61a, the cross-sectional area of the second engaging protrusion 62a is set to be larger than that of the first engaging protrusion 61a. The embodiment with a small cross-sectional area of the engaging protrusion 61a is not affected. In such an embodiment, even if a gap is generated between the second engaging protrusion 62a and the engaging hole 901b, and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com