Film pick-up and delivery device for residual film recovery machine

A recycling machine and film conveying technology, which is used in collectors, agricultural machinery and implements, applications, etc., can solve the problems of poor plastic film degradation ability, residual film falling, residual film retention, etc., and achieves high film picking efficiency. Good effect and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

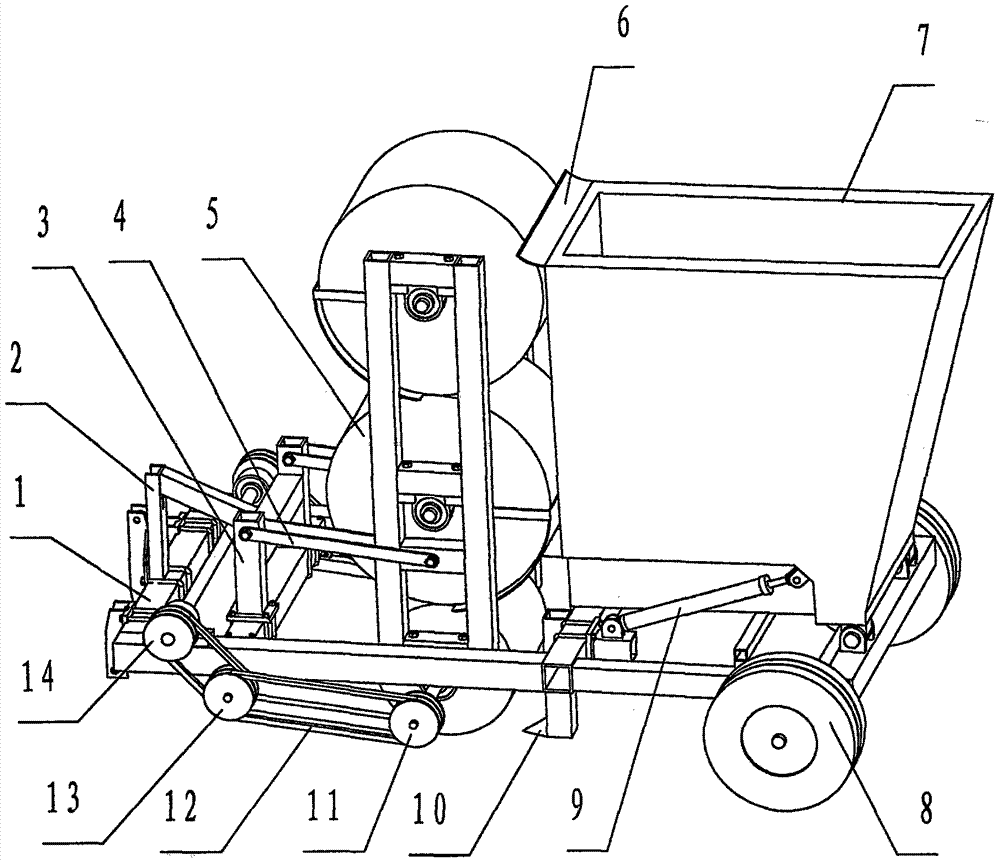

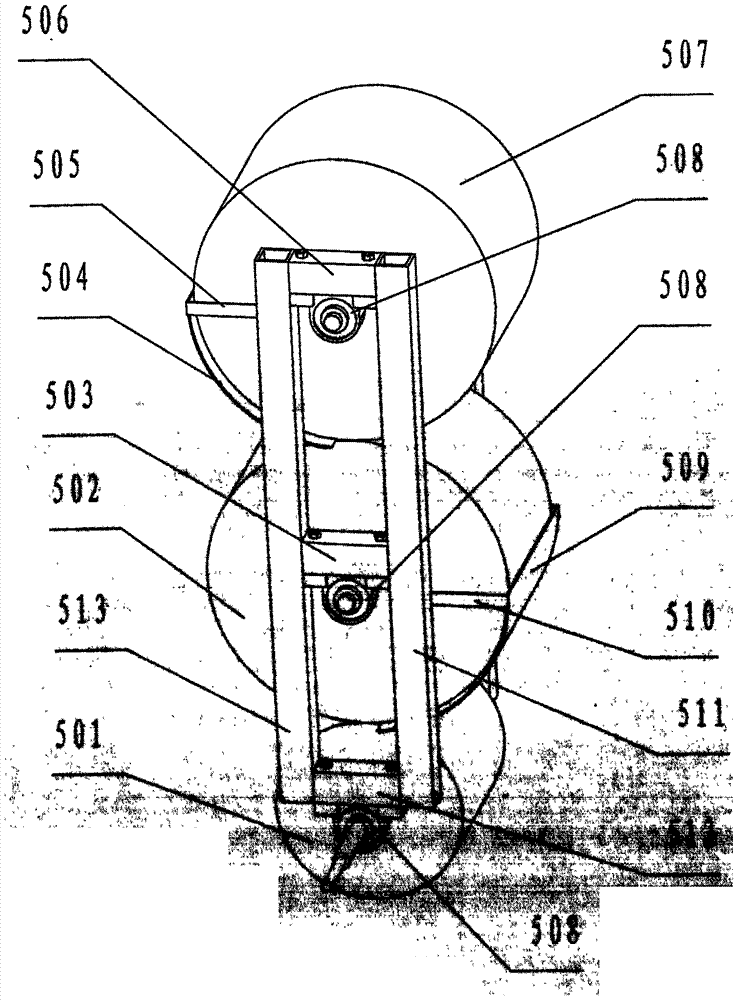

[0014] Embodiment 1: with reference to attached Figure 1~2 , the present embodiment comprises a frame 1, a suspension frame 2 arranged on the frame 1, a profiling four-bar connecting frame 3 and a profiling four-bar connecting plate 4 arranged behind the suspension frame 2, and a profiling four-bar connecting plate 4 arranged on the middle part of the frame 1. Pick up film and transport film device 5, be located at the film collection case 7 of frame 1 rear portion, be located at the comb film plate 6 on the film collection case 7, be located at the travel wheel 8 on the frame of film collection case 7, set The hydraulic cylinder 9 under the film collecting box 7, the film shovel 10, the transmission pulley I14, the transmission pulley II13, the transmission pulley III11 and the transmission belt 12 are arranged under the frame 1 of picking up the film delivery device 5 bottoms. Described film picking-up device 5 is made of fixed frame, film-picking roller 501, film-transmitt...

Embodiment 2

[0015] Embodiment 2: Compared with Embodiment 1, the difference lies in that: there are three film delivery rollers, and the profile surface of the film delivery rollers can be in the shape of interlaced stripes.

Embodiment 3

[0016] Embodiment 3: Compared with Embodiment 1, the difference lies in that: the number of film feeding rollers is set to four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com