Rubber shoe production line

A production line and rubber shoe technology, which is applied to footwear, shoemaking machinery, clothing, etc., can solve the problems of large footprint, achieve the effects of saving floor space, reducing turnover, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

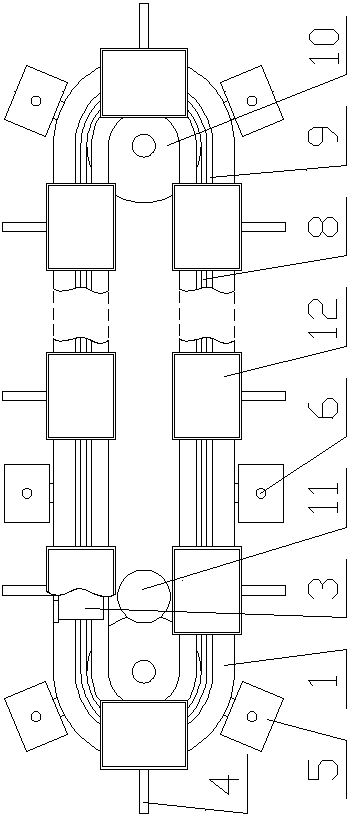

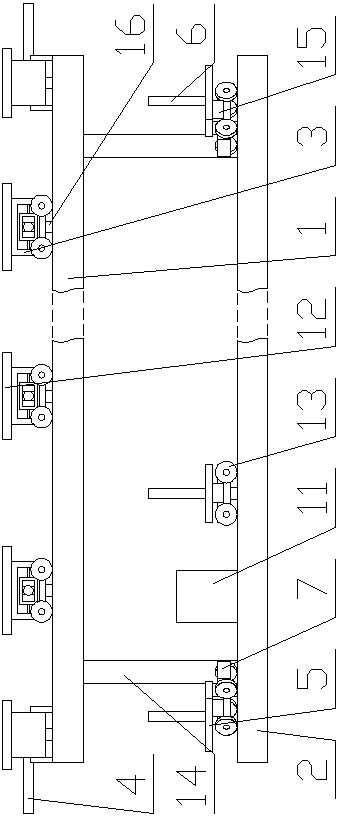

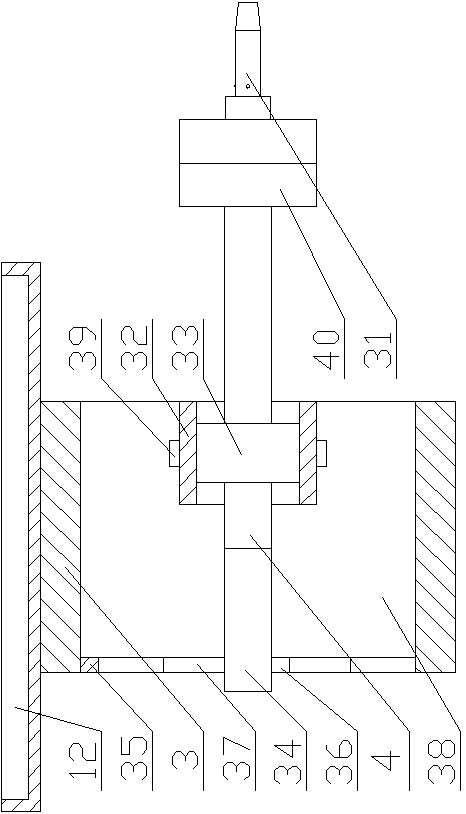

[0045] combine Figure 1~Figure 5 It can be seen that the present invention includes circular track A1 and circular track B2 parallel to each other, said circular track A1 is arranged above circular track B2, said circular track A1 is movably connected with a plurality of pedestals A3, said circular track B2 A plurality of pedestals B7 are movably connected, and the pedestal A3 and the pedestal B7 are respectively provided with a strut A4 and a strut B6 connected with the shoe last, and the pedestal A3 and the pedestal B7 are all passed through Drive chain 8 transmission connection, each described drive chain 8 is transmitted by drive wheel 10 respectively, and each described drive wheel 10 is connected with ring track A1 and ring track B2 rotation respectively, and the transmission speed of drive chain 8 of described ring track A1 and ring The transmission speed of the transmission chain 8 of the track B2 is equal; the base frame A3 is provided with a horizontal through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com