Girder-pier sequential construction method of pier top segment of auxiliary pier of cable stayed bridge

A construction method, the technology of beams first and piers later, is applied in bridges, bridge construction, erection/assembly of bridges, etc., which can solve the problems of high construction cost, long construction time, and large investment, and achieve compact connection, shorten construction period, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

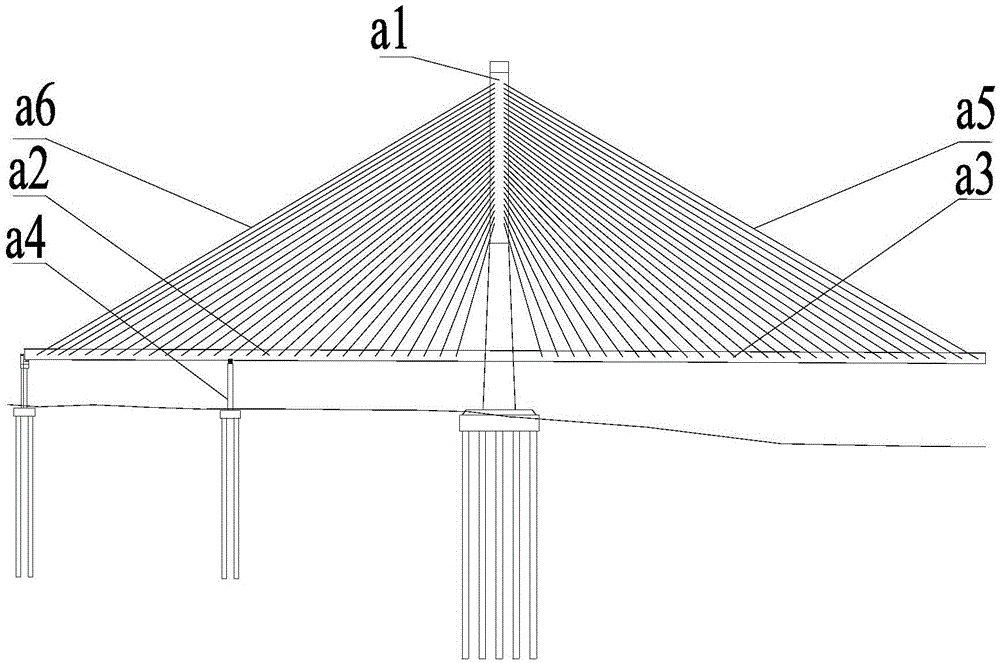

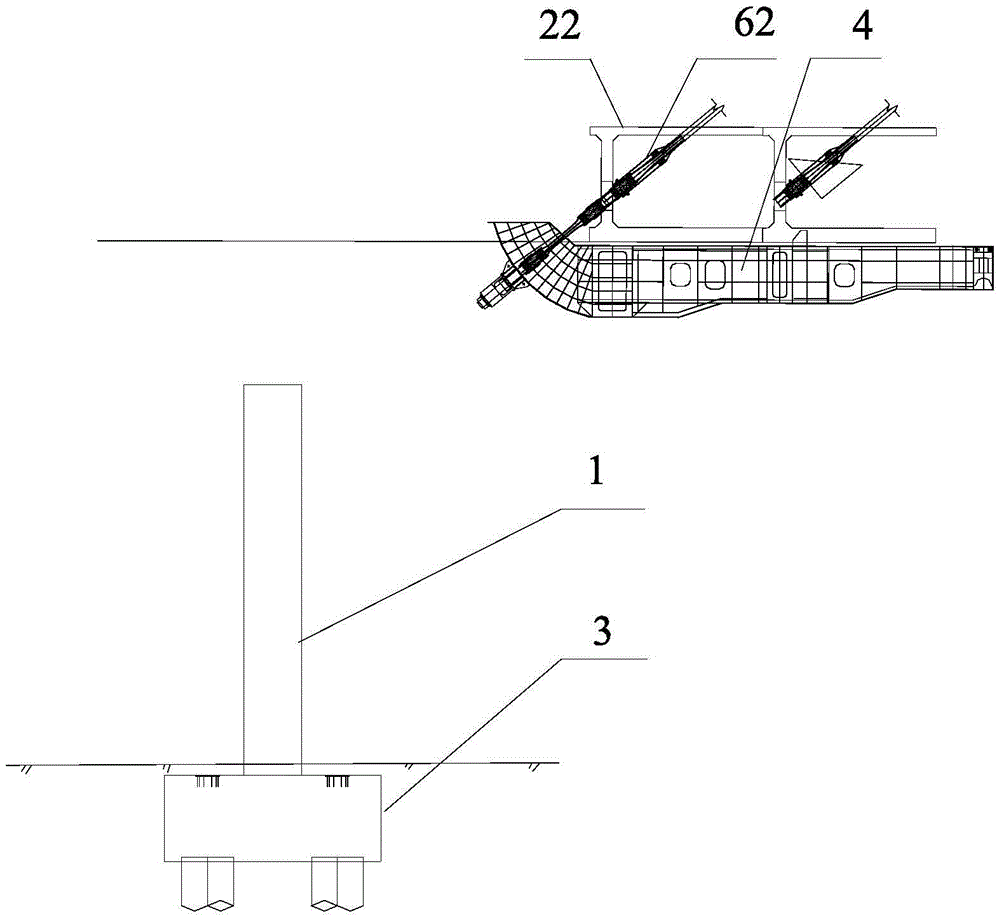

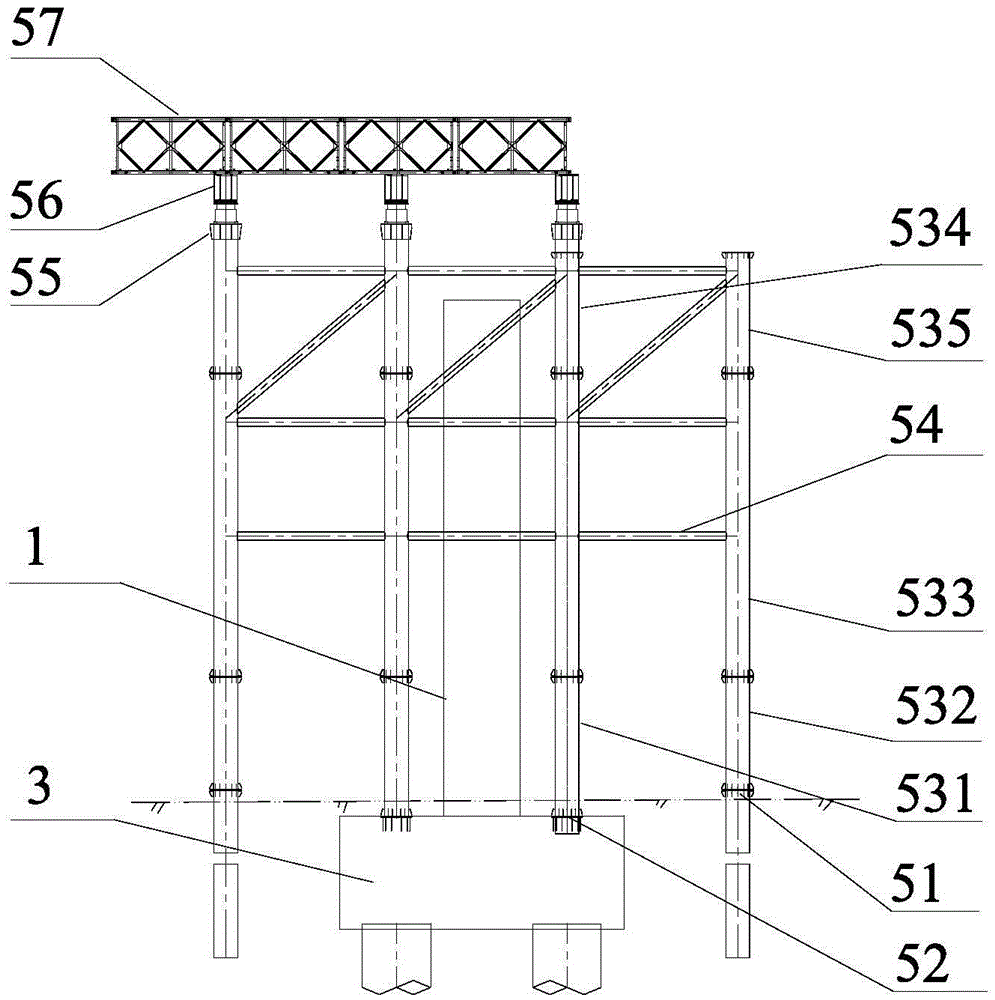

[0032]The embodiment of the present invention provides a construction method for the top section of the auxiliary pier of a cable-stayed bridge, which is characterized in that: the auxiliary pier body is constructed in two parts, and the pier top is reserved for the first construction of the auxiliary pier body. The height of the front fulcrum stay cable hanging basket 4 can walk through, use the cast-in-place support 5 to complete the construction of the main beam at the top of the auxiliary pier pier, remove the cast-in-place support 5, and the front fulcrum stay cable hanging basket 4 can walk through the auxiliary pier, The second construction assists the pier body 1 to the pier top, and installs the support 8. The main beam of the front and rear sections of the auxiliary pier share a set of front fulcrum stay cable hanging basket 4 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com