Miniature lubricating grease reaction kettle

A grease and reaction kettle technology, which is applied in the field of small grease reaction kettles, can solve problems such as the inability to meet the rapid and efficient requirements of R&D personnel, and achieve the effects of simple and easy technical means, easy popularization and application, and good explosion-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

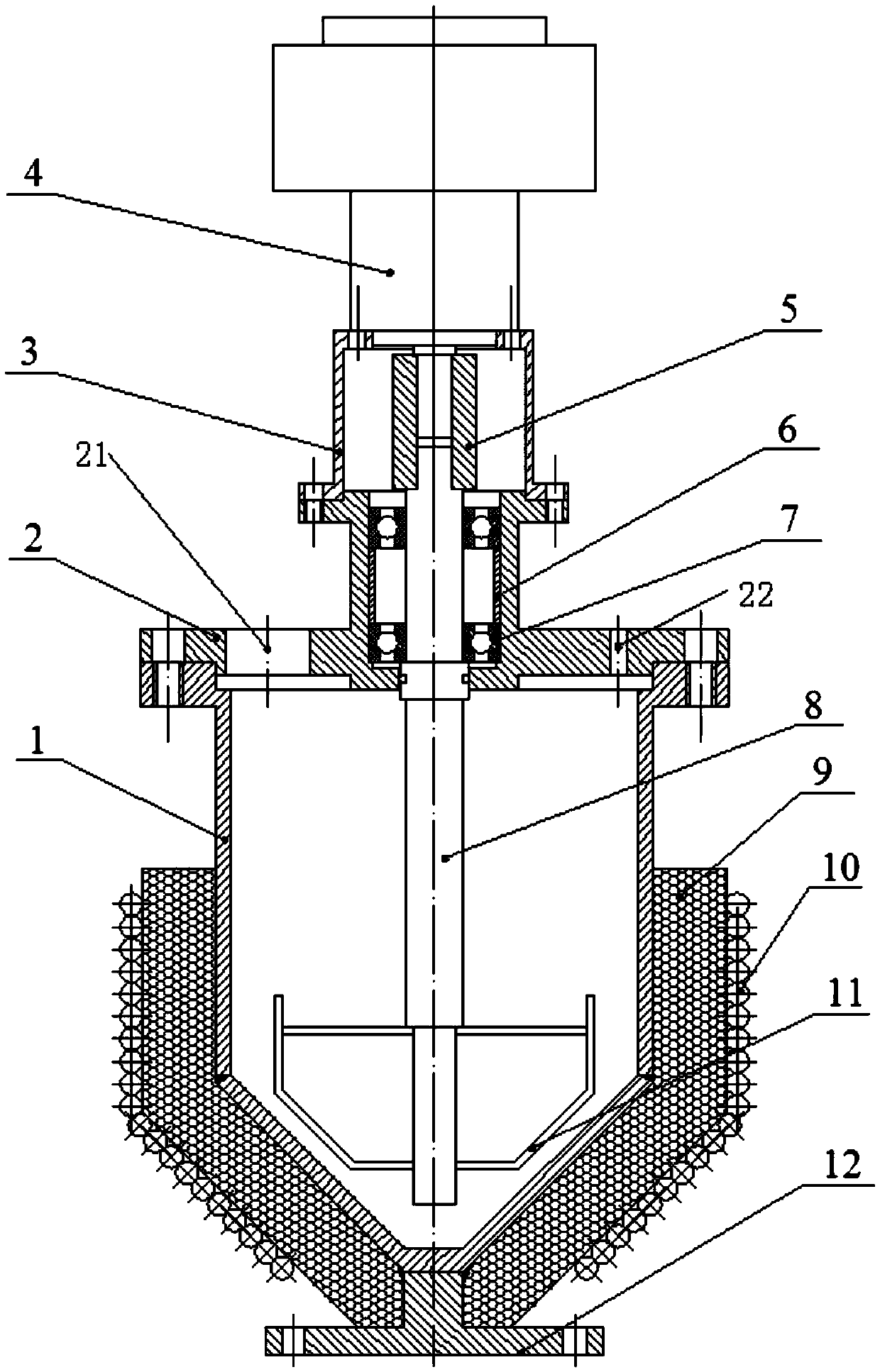

[0015] Such as figure 1 shown. The invention discloses a small grease reaction kettle, which comprises a kettle body 1, a stirring shaft 8 arranged in the kettle body 1, a kettle cover 2 arranged on the top of the kettle body 1, a base 12 arranged on the kettle body 1, and a set The air motor 4 on the kettle cover 2; the air motor 4 is connected with the kettle cover 2 through the motor support 3, and the rotating shaft of the air motor 4 is connected with the stirring shaft 8 through the coupling sleeve 5.

[0016] Described stirring shaft 8 is connected with kettle cover 2 by two bearings 7, and stirring shaft 8 is equipped with stirring paddle 11 at one end in the still body, and is provided with bearing positioning sleeve 6 between these two bearings 7, through bearing positioning sleeve 6 The two bearings 7 are spaced apart.

[0017] The kettle cover 2 has a feeding port 21 and a thermometer hole 22 .

[0018] The outside of the kettle body 1 is wrapped with glass insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com