Multifunctional storage tank liquid level instrument

A liquid level meter and multi-functional technology, which is applied to the measurement field of interface and liquid temperature density, can solve the problems of difficulty in measuring oil-water interface by radar liquid level meter, affecting the measurement accuracy of liquid level meter, and difficult to install due to high range, so as to achieve measurement The effect of data security and reliability, simple structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

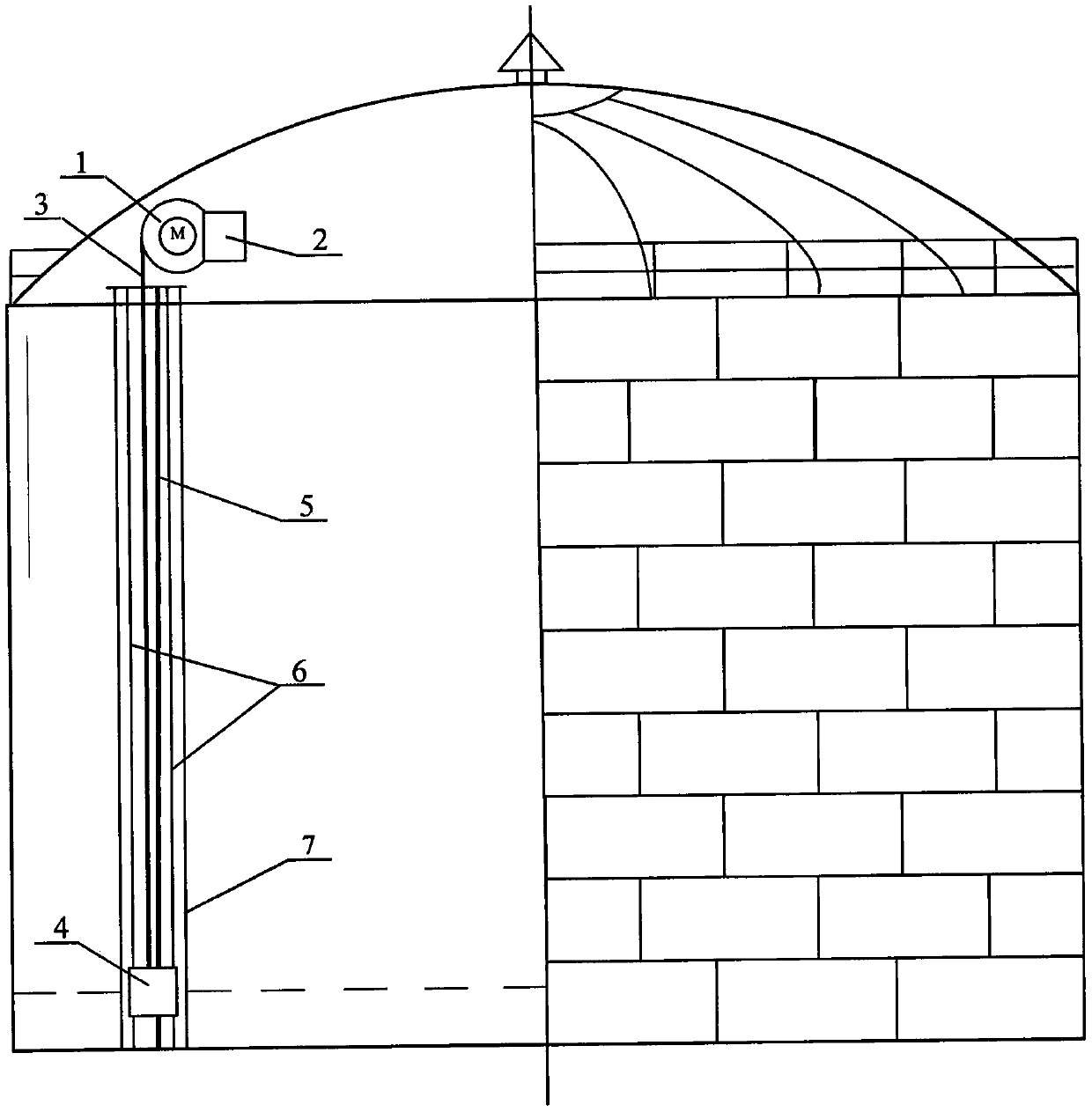

[0007] The working process of the liquid level gauge is described below with the help of a structural diagram:

[0008] Liquid level measurement: After the liquid level gauge accepts the instructions from the on-site controller or the remote control (monitoring room), when the storage tank adds liquid and the liquid level rises, the liquid level exceeds the detection probe of the measuring box, and the measuring box issues instructions, which are controlled by the signal transmission belt The hub of the servo motor rotates clockwise, the measuring box moves up along the guide wire and obtains the height information on the steel belt; the liquid level keeps rising, and the above process is repeated until the storage tank stops adding liquid and the liquid level is stable. The detection probe is at the liquid-gas interface; when the liquid in the storage tank is reduced and the liquid level drops, the detection probe of the measuring box is exposed to the liquid level, the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com