A self-resetting energy-dissipating support of a piston-type filling compression spring

A self-resetting, piston-type technology, applied to building components, shockproof, etc., can solve the problems of increased maintenance and reconstruction costs, cumbersome production and processing, and complex structure, etc., to achieve obvious shock absorption effect, convenient production and processing, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

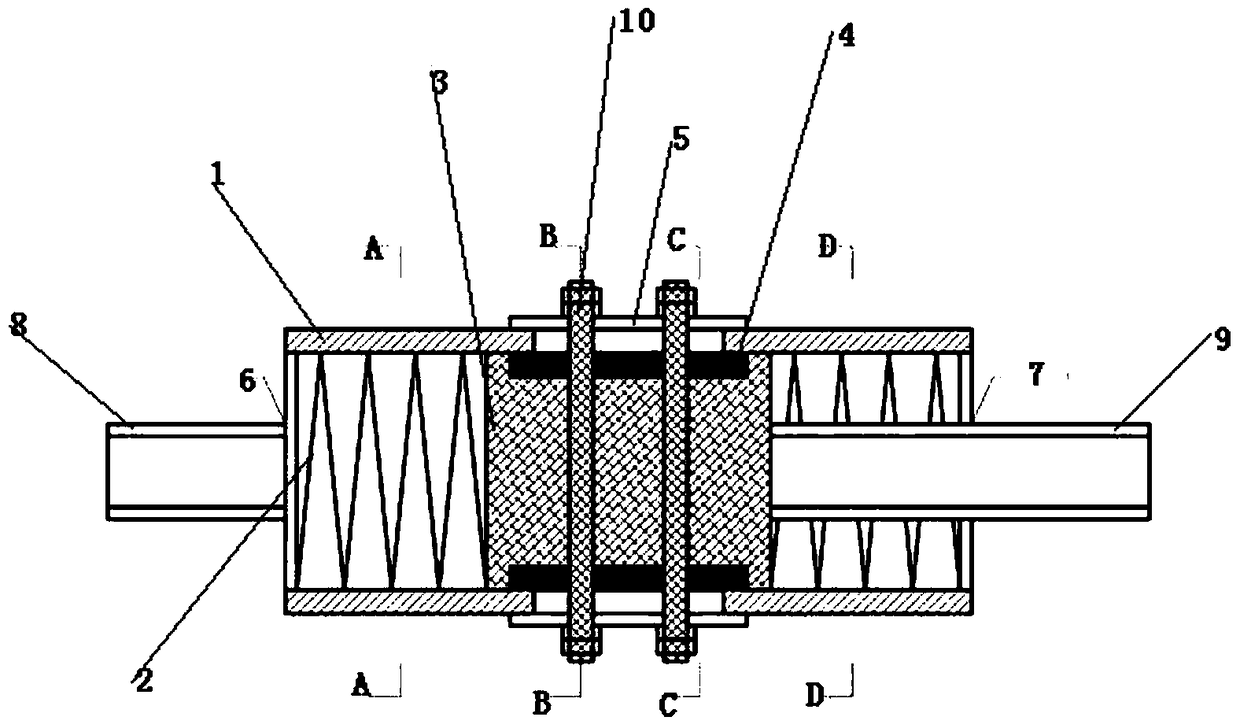

[0023] Specific embodiments: The structure and implementation of the piston-type friction self-resetting support will be described in conjunction with the accompanying drawings.

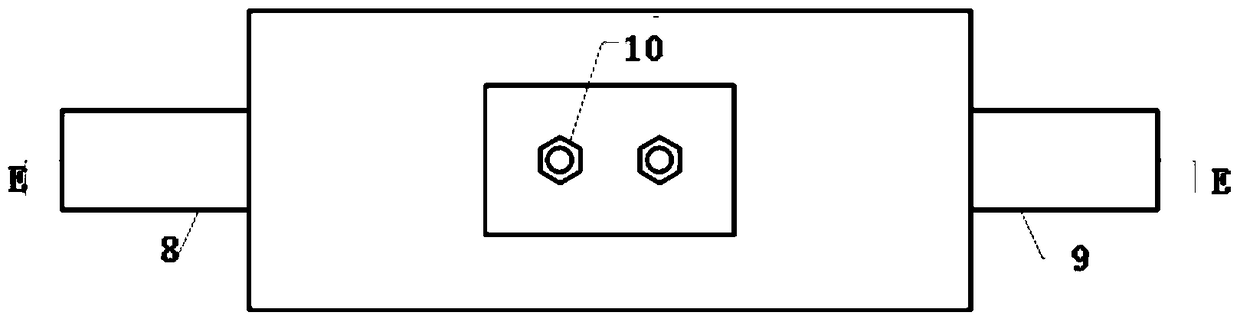

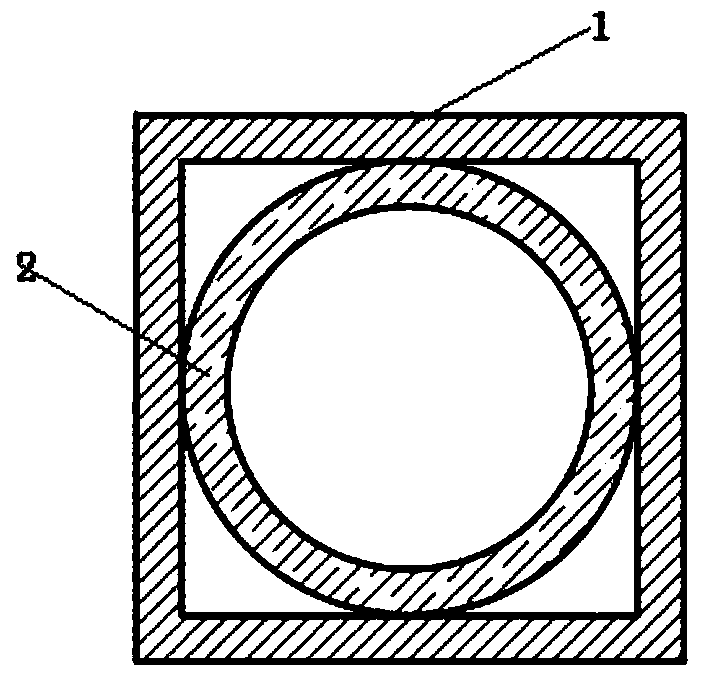

[0024] The friction part is composed of a left connecting rod, an outer sleeve, a piston head, a right connecting rod, a friction plate, a backing plate and high-strength bolts. There is a bar-shaped groove in the middle of the upper and lower surfaces of the outer sleeve, and two backing plates cover the grooves on the upper and lower surfaces of the outer sleeve respectively. The left baffle is welded to the left end of the outer sleeve, the right baffle is welded to the right end of the outer sleeve, and the right There is a hole in the middle of the baffle. The upper and lower surfaces of the piston head also have a concave groove. Two friction plates are respectively fixed in the grooves on the upper and lower surfaces of the piston head. A group of high-strength bolts penetrate the upper backin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com