Device and method for measuring center thickness of spherical parts

A technology of central thickness and measuring devices, applied in measuring devices, instruments, etc., can solve the problems of low thickness measurement efficiency and achieve simple and reliable measurement, high measurement efficiency and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

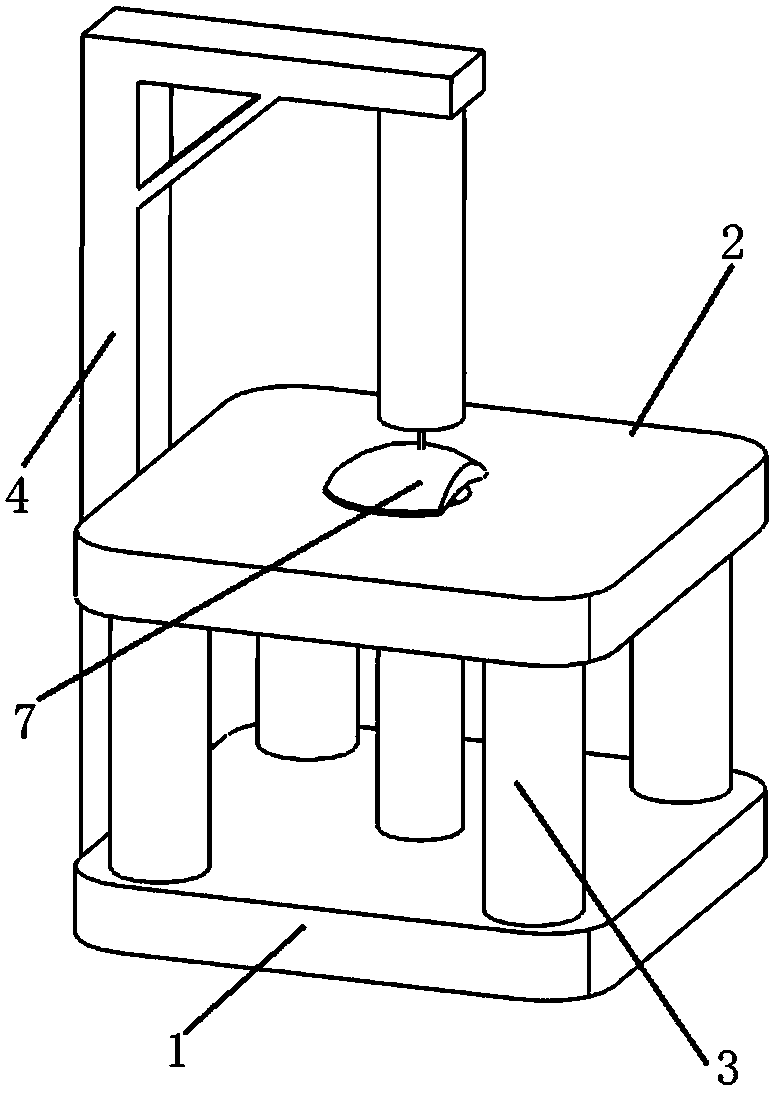

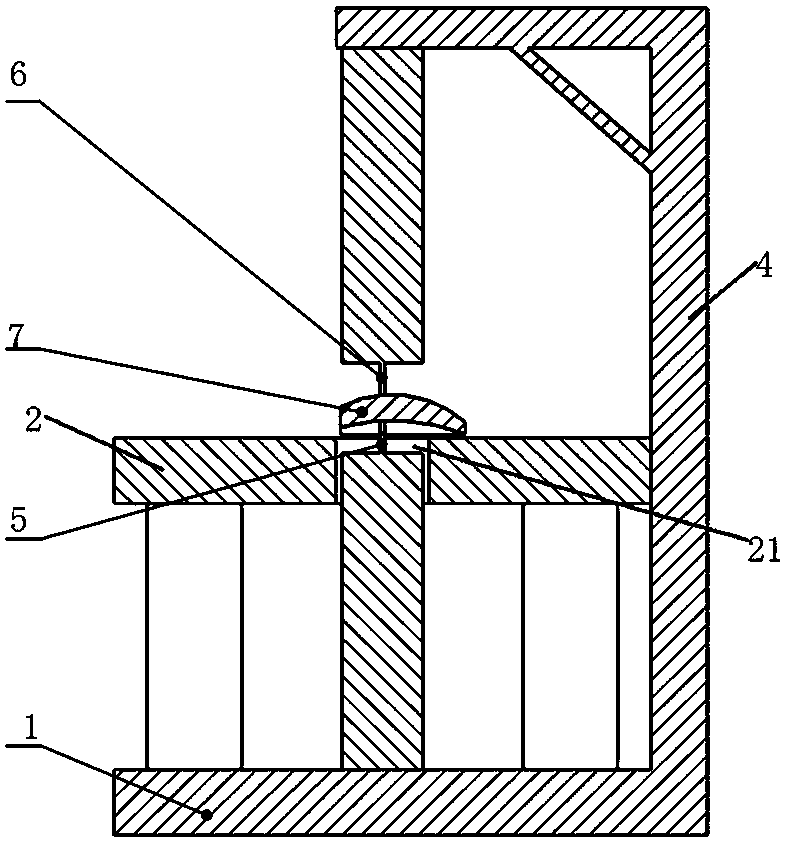

[0017] Such as figure 1 , figure 2 Shown, a kind of embodiment of spherical lens central thickness measuring device, the measuring device in this embodiment comprises base 1, and base 1 is fixedly provided with support 2 for supporting and placing spherical lens 7 to be measured by pillar 3, Above the support 2, there is an upper measuring head 6 that can move back and forth along the up and down direction for contacting the upper measuring head 6 pressed on the upper side of the spherical lens 7 to be measured and an upper displacement sensor (not shown in the figure) for detecting the displacement of the upper measuring head. display), the upper measuring head 6 and the upper displacement sensor are both arranged on the bracket 4, and the bracket 4 is arranged on the base 1. A measuring notch 21 is provided on the support 2 below the upper measuring head 6 . The measuring device also includes a lower measuring head 5 that is used in conjunction with the upper measuring he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com