3D magnetic coil with large uniform region and manufacture method of 3D magnetic coil

A uniform area, magnetic coil technology, applied in coil manufacturing, coil, magnetic resonance measurement, etc., can solve the problems of inconvenient assembly of components in the coil, the uniformity cannot meet the high uniformity of the longitudinal coil, and the occupation volume is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

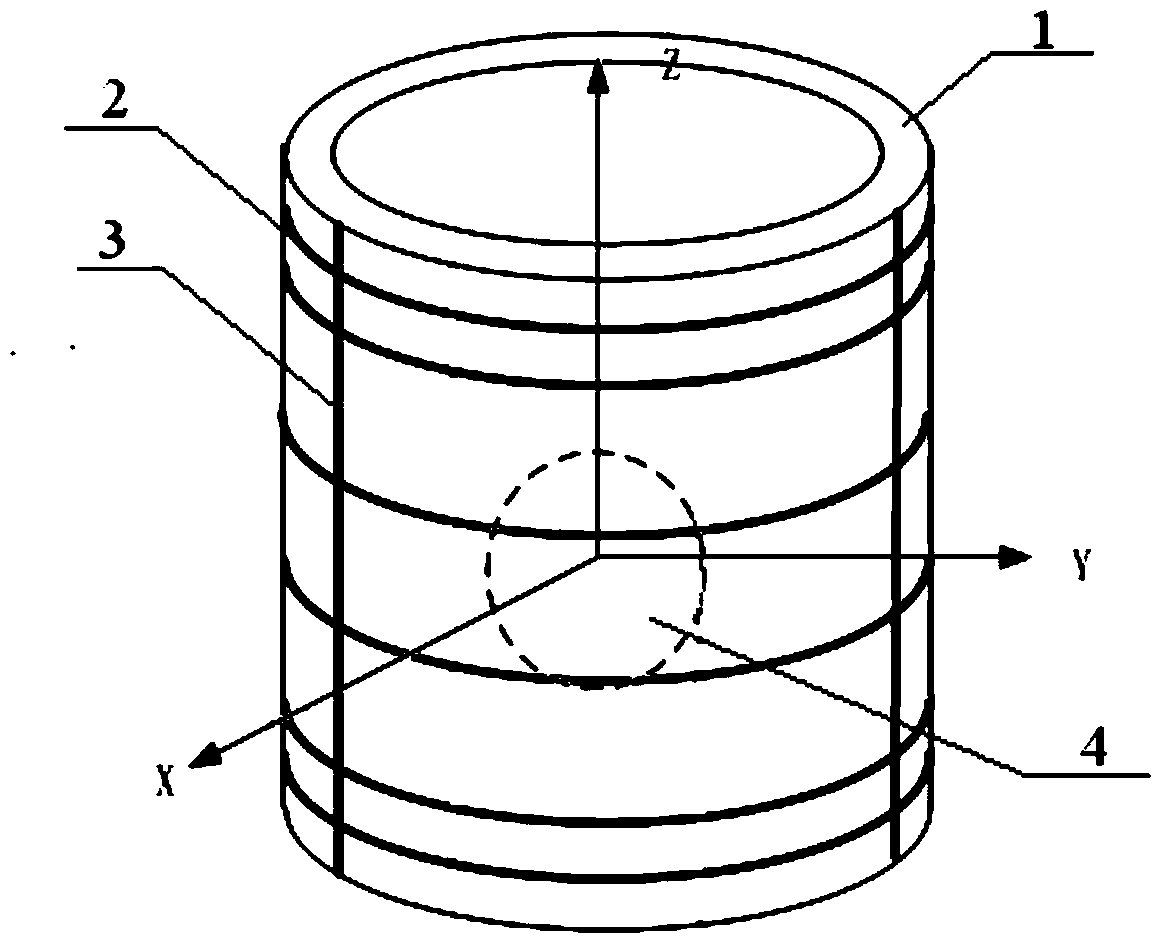

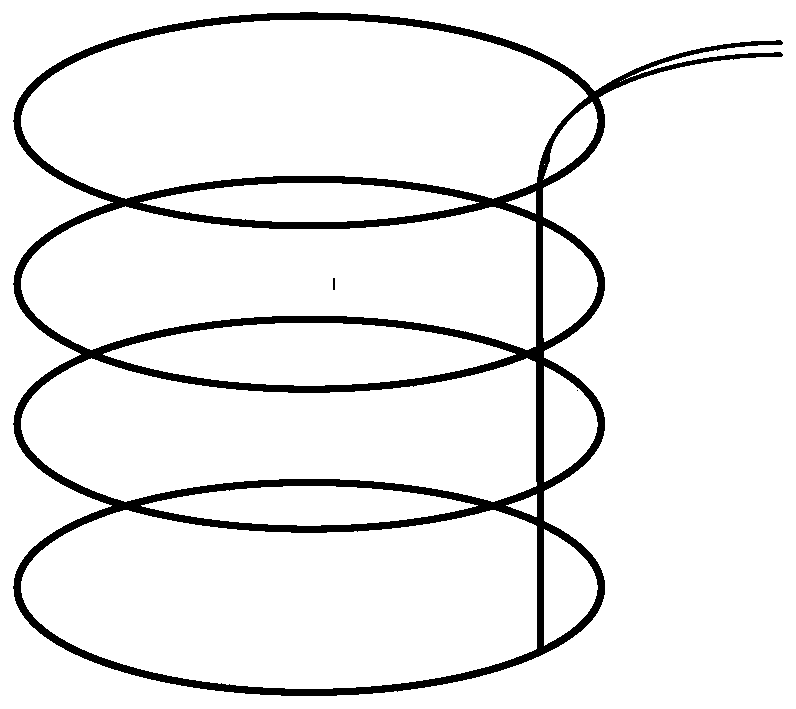

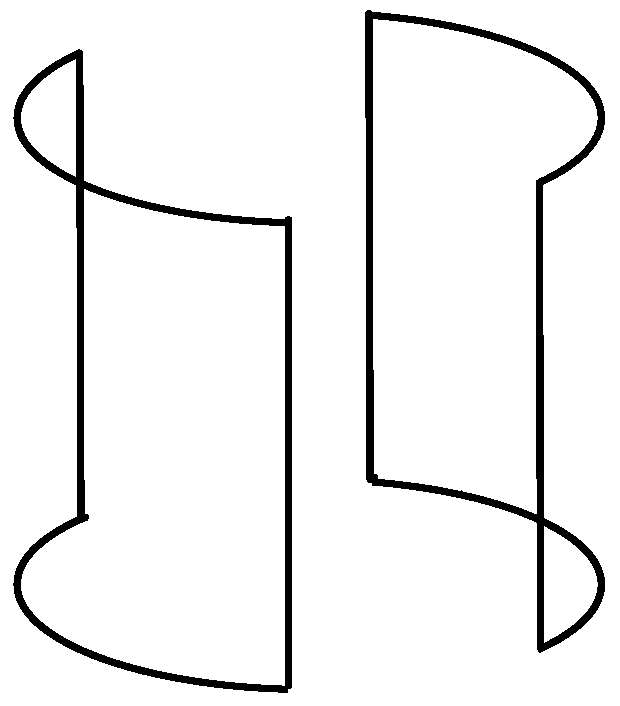

[0042] A three-dimensional magnetic coil with a large uniform area, such as figure 1 As mentioned above, it includes a support body 1 , a longitudinal coil 2 and a horizontal coil 3 . The support body 1 is cylindrical with open upper and lower bottom surfaces, and wire grooves are respectively arranged on the surface of the support body 1 along its circumferential and axial directions for installing the longitudinal coil 2 and the horizontal coil 3. The quantity is determined according to the quantity of longitudinal stitches 2 and horizontal stitches 3 . The longitudinal coil 2 is composed of wires wound circumferentially around the surface of the support 1, and two adjacent longitudinal coils 2 are parallel and communicated through the wires, such as figure 2 shown. The horizontal coil 3 is composed of wires wound around the axial direction of the surface of the support body 1 and the arcs of the upper and lower bottom surfaces, forming a space curved quadrilateral in spa...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the number of turns of each longitudinal coil 2 is 1 or more than 1 turn, and the number of the longitudinal coils 2 is 3, 4 or more.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 or 2 is that the support body 1 is a square tube or other centrally symmetrical cylindrical structure, and the horizontal coil 3 is wound around the groove direction of the surface of the support body 1 and the edge fold lines of the upper and lower bottom surfaces. It is composed of wires and forms a space quadrilateral, hexagon, octagon or other space polygonal shapes in space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com