Lens, light source module and lighting device

A light source module and lens technology, applied in lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of small light output angle and poor uniformity, and achieve uniformity, high uniformity, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

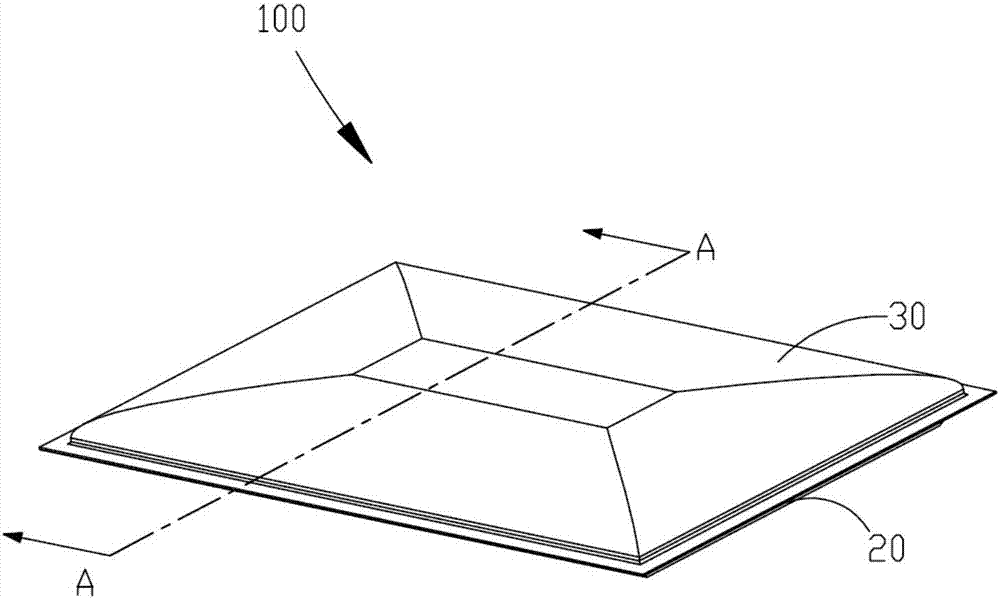

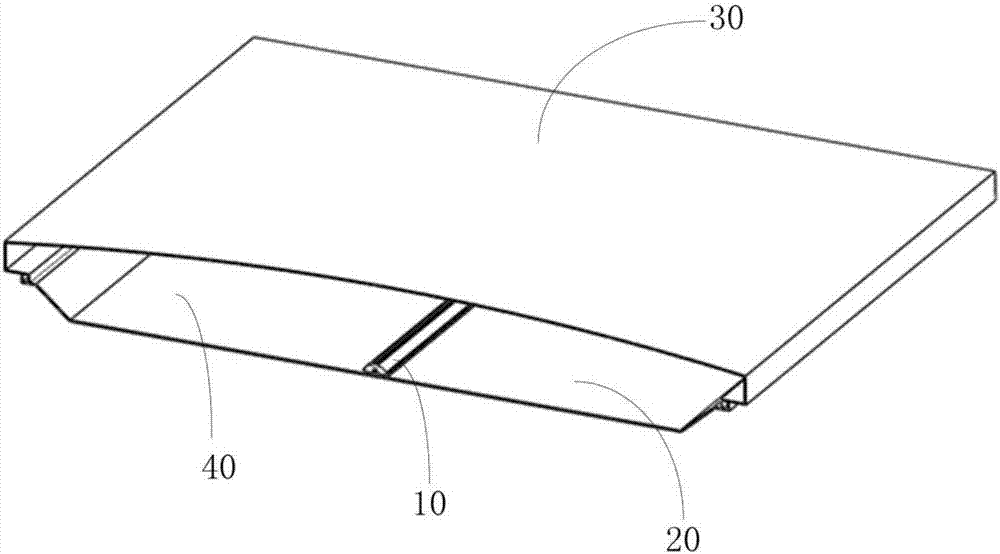

[0058] Figure 1 to Figure 3A lighting device 100 of the present invention is shown, including a chassis 20 , a mask 30 connected to the chassis 20 , and a light source module 10 fixed on the chassis 20 . Wherein, the mask 30 and the chassis 20 are connected to form a second receiving chamber 40 , and the light source module 10 is housed in the second receiving chamber 40 . The light source module 10 of the embodiment of the present invention can be used alone in lamps such as ceiling lamps or advertising light boxes.

[0059] In the following, each component and the connection relationship between the components in the lighting device 100 provided by Embodiment 1 of the present invention will be described in detail.

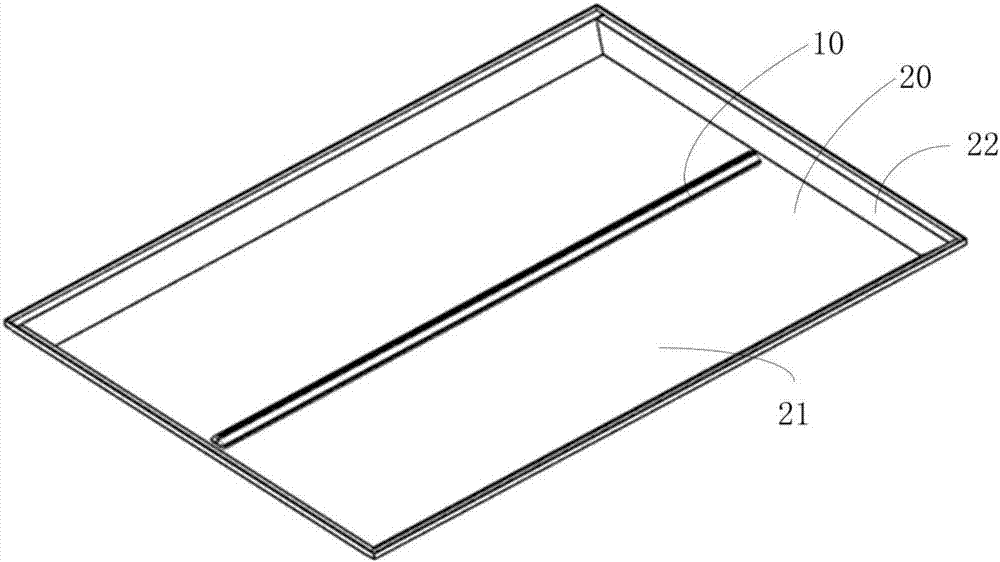

[0060] Such as Figure 1 to Figure 3 As shown, the chassis 20 is roughly in the shape of a cuboid, and has a flat bottom plate 21 and side walls 22 vertically extending from the bottom plate 21 . The width of the chassis 20 is greater than 550 mm, and it can ...

Embodiment 2

[0076] see Figure 10 As shown, Embodiment 2 of the present invention provides a lens 1a used in the lighting device 100 provided by Embodiment 1 of the present invention. The lens 1a is also linear, and its cross-sectional structure is the same as that of the lens 1 in Embodiment 1. structure is similar. The lens 1a has an inner surface 11a, an outer surface 12a, a bottom surface 13a, and a first cavity 110a for accommodating a light emitting unit (not shown). The wall of the first cavity 110a is the inner surface 11a of the lens 1a.

[0077] The only difference between the lens 1a and the lens 1 in the first embodiment is that the first light incident surface 111a of the lens 1a is a curved surface protruding toward the first receiving cavity 110a.

Embodiment 3

[0079] see Figure 11 As shown, Embodiment 3 of the present invention provides a lens 1b used in the lighting device 100 provided by Embodiment 1 of the present invention. The lens 1b is also linear, and its cross-sectional structure is the same as that of the lens 1 in Embodiment 1. structure is similar. The lens 1b has an inner surface 11b, an outer surface 12b, a bottom surface 13b, and a first cavity 110b for accommodating a light emitting unit (not shown). The wall of the first cavity 110b is the inner surface 11b of the lens 1b.

[0080] The only difference between the lens 1b and the lens 1 in Embodiment 1 is that the first light incident surface 111b of the lens 1b is a plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com