Disassembling device for clamp nut with rubber protective sleeve and using method

A technology for fastening nuts and dismantling devices, which is applied in the direction of screwdrivers, manufacturing tools, wrenches, etc., can solve the problems of inconvenient disassembly, damage, and inability to perform non-destructive disassembly, and achieve saving of electrical components, high work efficiency, and good use prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

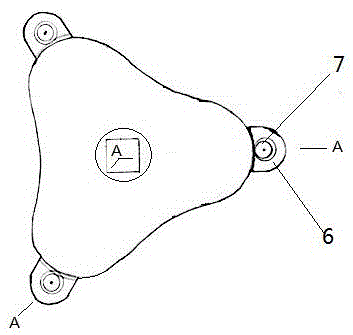

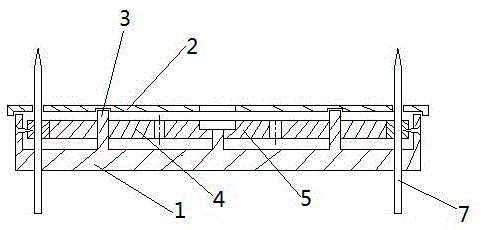

[0017] A fastening nut removal device with a rubber sheath, comprising a housing 1 and an end cover 2, characterized in that the housing is provided with a driven gear shaft 3 distributed in an equilateral triangle, and three driven gears 4 are respectively installed on the driven gear On the shaft and respectively meshing with the central gear 5, three driven gears 4 are respectively provided with lugs 6 with central holes at the outermost ends of the central gear, and the central holes of the lugs 6 are provided with fastening clips with sharp corners at the front end. Claw 7, the lug wall is provided with a positioning screw to adjust the extension length of the fastening claw, the end cover and the central gear are provided with a wrench socket, the shell and the end cover are in the shape of a plum blossom that is divided into three equal parts, and the side wall of the shell Three arc-shaped concave plates are used to form three semi-circular passive gear guards smoothly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com