tool storage

A technology for storing devices and tools, applied in tool storage devices, manufacturing tools, etc., which can solve the problems of confusing tool placement, inability to place tools in designated positions, and difficult supervision of tool use status, so as to avoid placement errors and facilitate The effect of the state of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

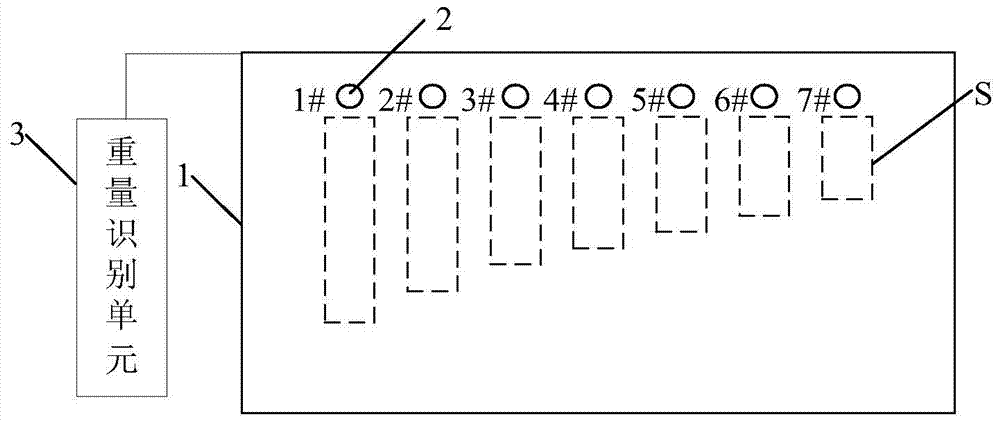

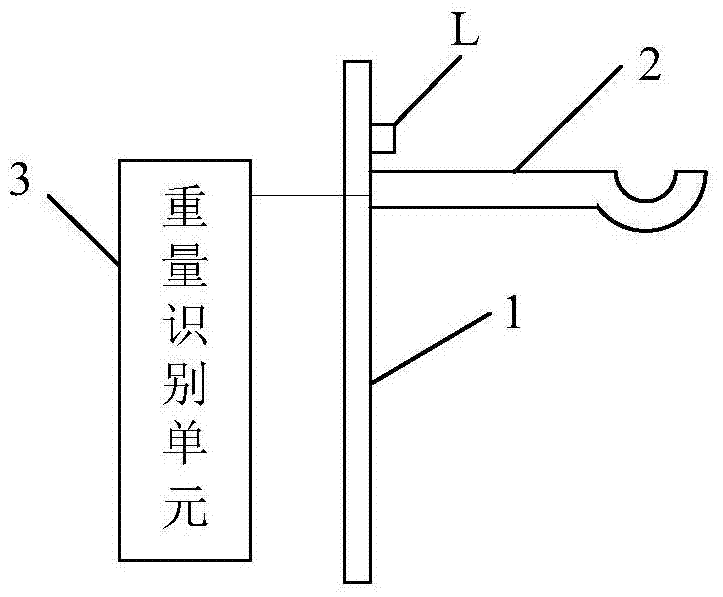

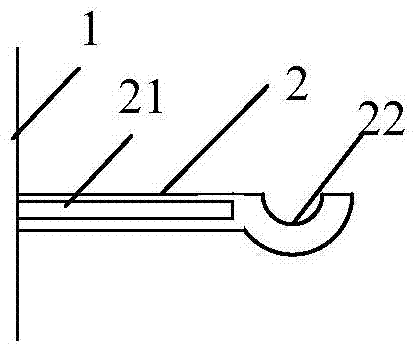

[0029] Figure 1a and Figure 1b It is a schematic view of the front and side structures of an embodiment of the tool storage device provided by the embodiment of the present invention, respectively. Such as Figure 1a and Figure 1b As shown, its structure includes: a hanging board 1, a plurality of weighing pendants 2 arranged on the hanging board 1 and a weight identification unit 3 connected with the weighing pendant 2; when the weighing pendant 2 is used for hanging tools, the measuring tool weight, and generate data used to characterize the weight of the tool; the weight identification unit 3 is used for data identification of the weight data, that is, to determine the actual weight value of the hanging tool according to the data, and compare the actual weight value with the prestored weight value Compare, and generate the result information that the tool is placed correctly or incorrectly according to the comparison result.

[0030] Specifically, the above-mentioned w...

Embodiment 2

[0039] This embodiment is a further preferred mode, on the basis of the above embodiments, such as Figure 6 As shown in , the above-mentioned tool storage device may also include: a display unit 4 connected to the weight identification unit 3 for displaying whether the tool hanging position output by the weight identification unit 3 is correct or wrong, and the display method may be The control indicator light L is used to display the difference between whether the hanging position is correct or wrong, and voice or text prompts can also be provided.

[0040] The weight identification unit 3 is also used to generate a tool used to indicate that the tool is taken away when it is recognized that the actual weight value of the hanging tool is less than the preset threshold (lower than the preset threshold indicates that there is no tool hanging on the weighing pendant 2). The first status information of the tool, and when the actual weight value is consistent with the pre-stored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com