Method for manufacturing a wind turbine blade, a wind turbine blade manufacturing facility, wind turbine blades and uses hereof

a manufacturing facility and wind turbine technology, applied in the field of wind turbine blade manufacturing facilities, can solve the problems of reducing the aerodynamic qualities of the blade, reducing the weight of the blade, and affecting the performance of the blade, so as to achieve the effect of reducing the weight of the blade, and maintaining the shap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

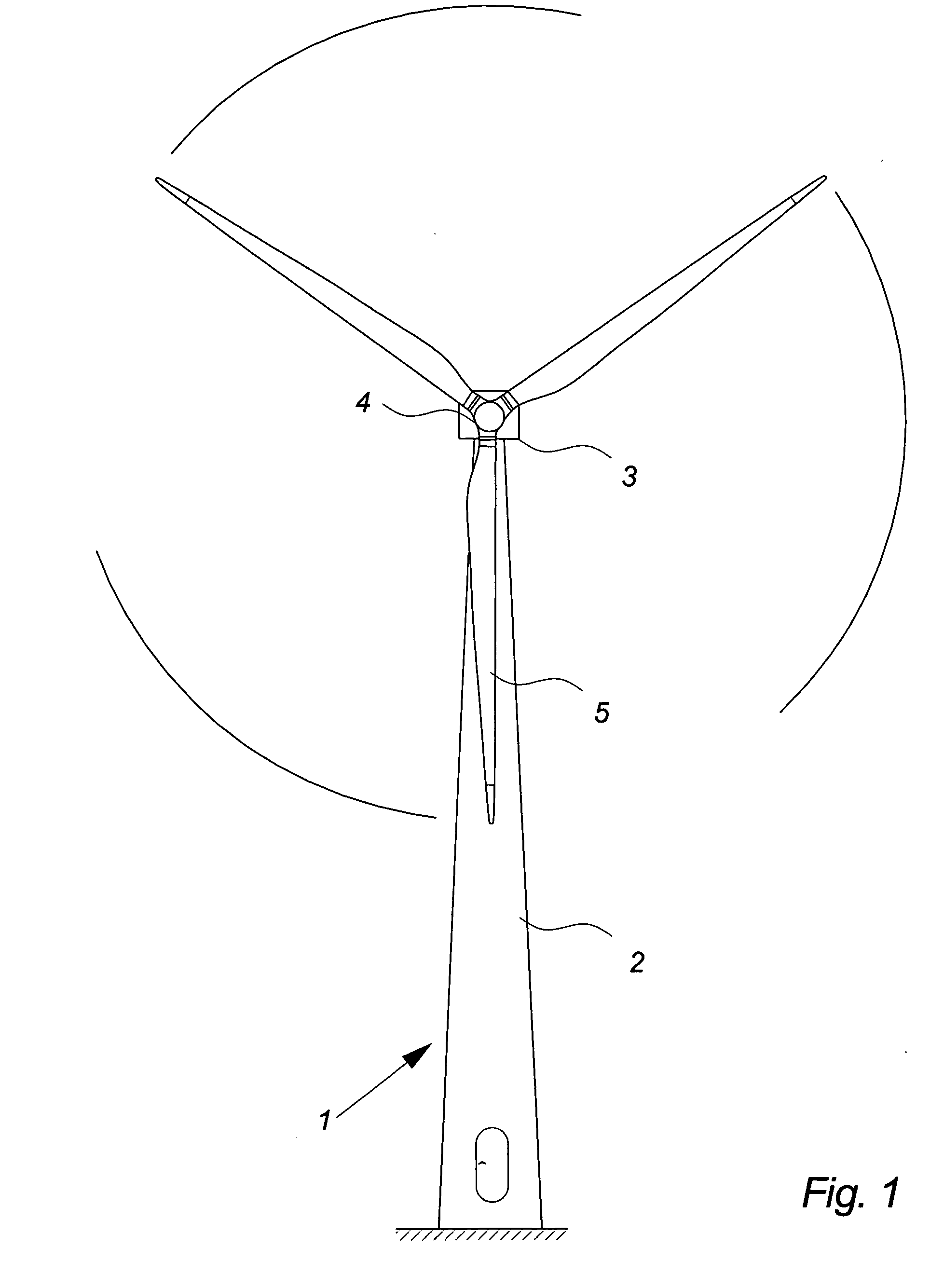

[0106]FIG. 1 illustrates a modern wind turbine 1, comprising a tower 2 and a wind turbine nacelle 3 positioned on top of the tower 2. The wind turbine rotor 4, comprising three wind turbine blades 5, is connected to the nacelle 3 through the low speed shaft which extends out of the nacelle 3 front.

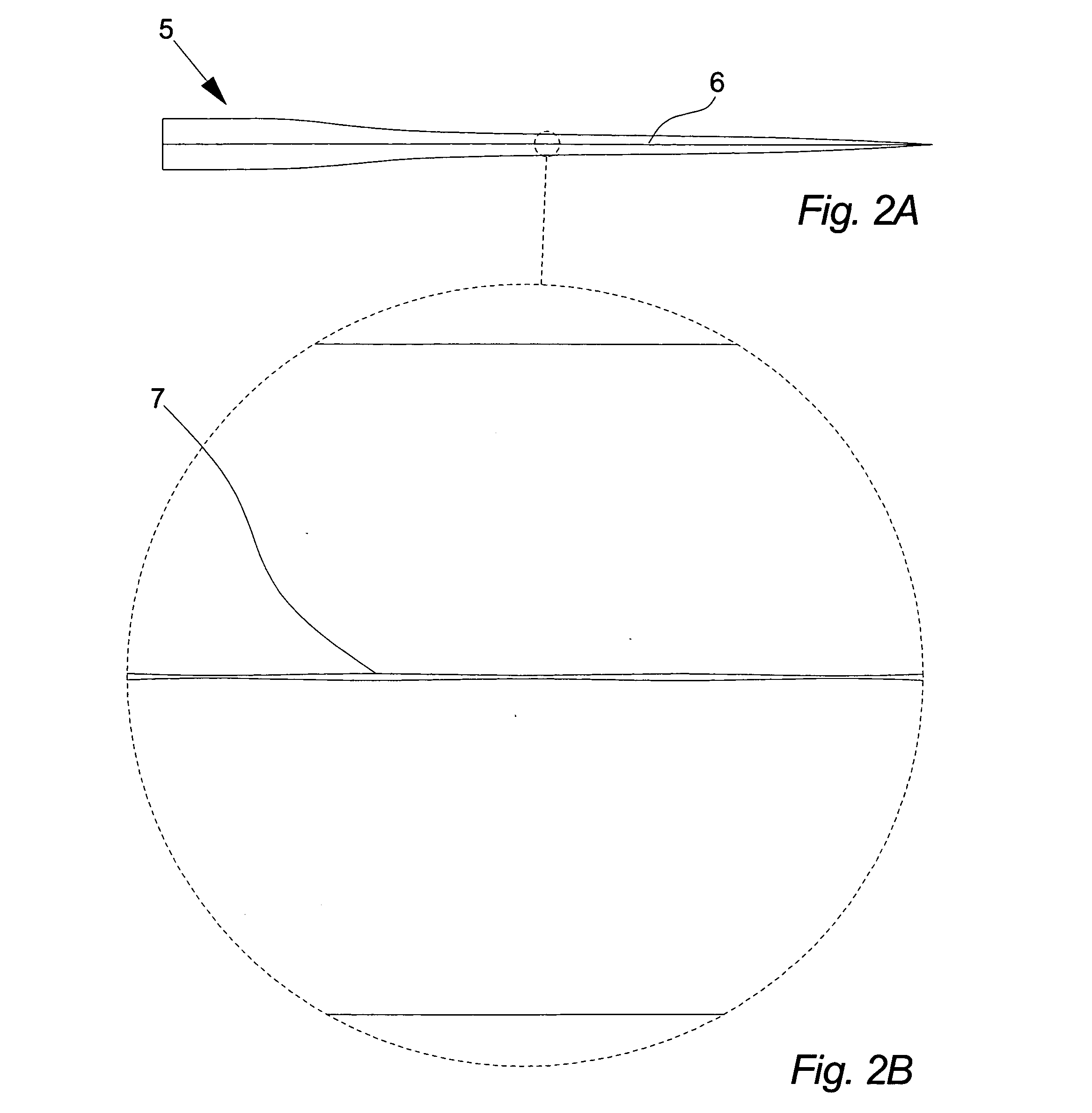

[0107]FIG. 2A illustrates a wind turbine blade 5 as seen from the side. As illustrated a wind turbine blade 5 known in the art is made of two substantially identical blade halves connected in a joint 6 by means of adhesive. To keep the two blade halves pressed firmly together while the adhesive is hardening the known method is to apply pressure to the blade halves, either by means of straps tightened around the halves, by means of hydraulic or pneumatic actuators or other methods applying pressure in a number of specific points.

[0108]FIG. 2B illustrates a section of the same wind turbine blade 5 as illustrated in FIG. 2A, where the wave like shape of the joint 7 is clearly shown.

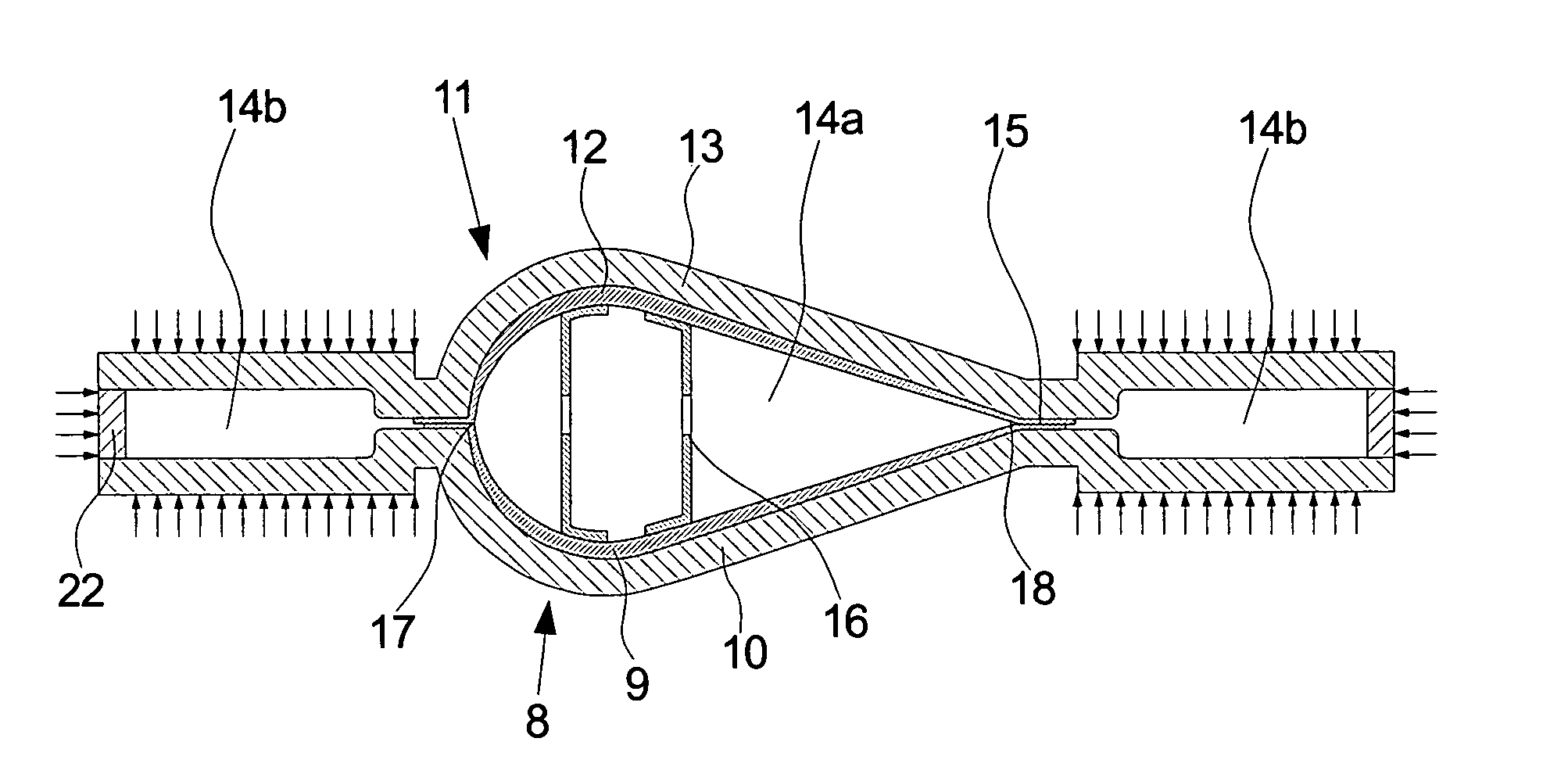

[0109] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressing force | aaaaa | aaaaa |

| compressing force | aaaaa | aaaaa |

| compressing force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com