a damper wheel

A shock-absorbing wheel and outer wheel technology, applied in springs/shock absorbers, wheels, high-elastic wheels, etc., can solve the problems of the impact of shaft life and high requirements on the strength of elastic components, and achieve reliable grip performance, good performance, and reduced burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

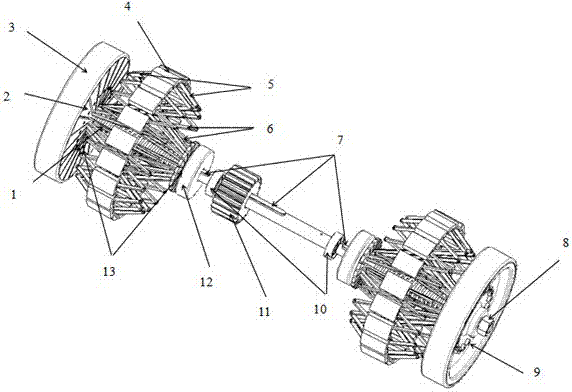

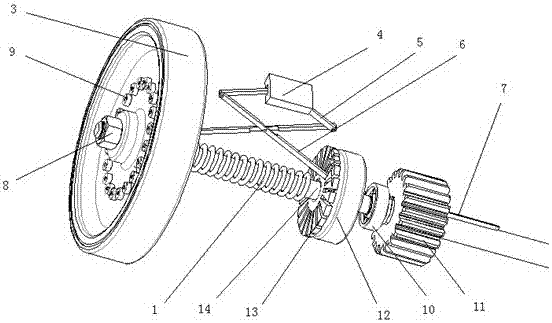

[0023] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0024] The invention provides a shock absorbing wheel. This application utilizes the characteristics that the umbrella frame can convert the axial change into a radial change, and the radial change is very large. The wheel and the shock absorber are combined to directly make a shock absorber. Shock wheel, the shock-absorbing wheel has good mechanical properties, and the diameter of the wheel can be changed with the size of the weight, thereby changing the size of the power assist. The heavier the weight, the greater the force generated by the guide bar, and at the same time the diameter of the wheel decreases, which increases the force of the wheel against the ground.

[0025] As an embodiment of the present invention, the present invention provides such as figure 1 and 2 A kind of damping wheel shown, comprises extension spring 1, outer wheel 2, outer wheel rubber 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com