Garbage basket

A technology of garbage baskets and basket bottoms, which is applied in trash cans, garbage collection, household appliances, etc., can solve the problems of easy sliding, easy damage, insufficient strength of plastic bags, etc., and achieve the effect of not being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

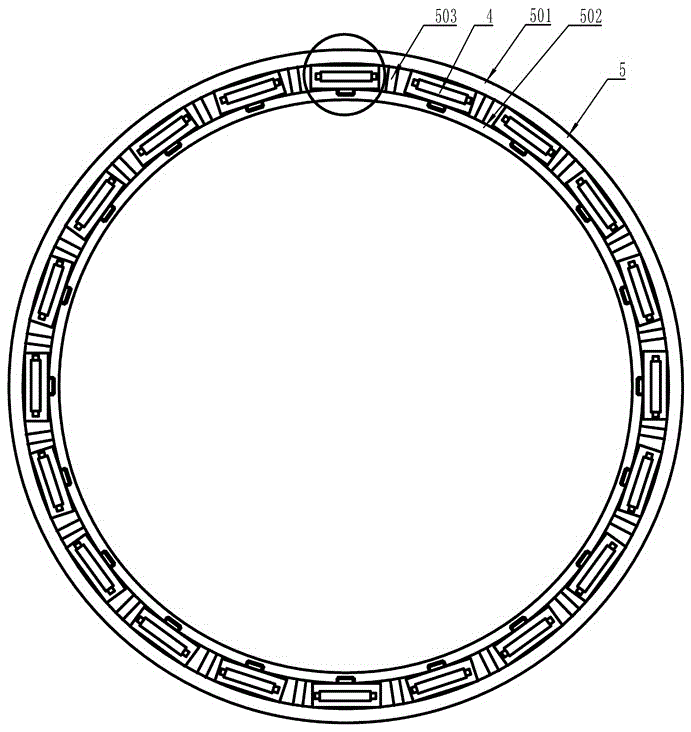

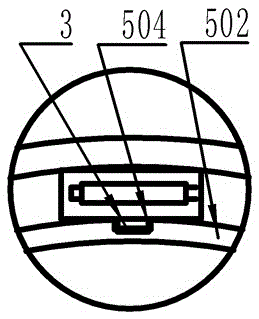

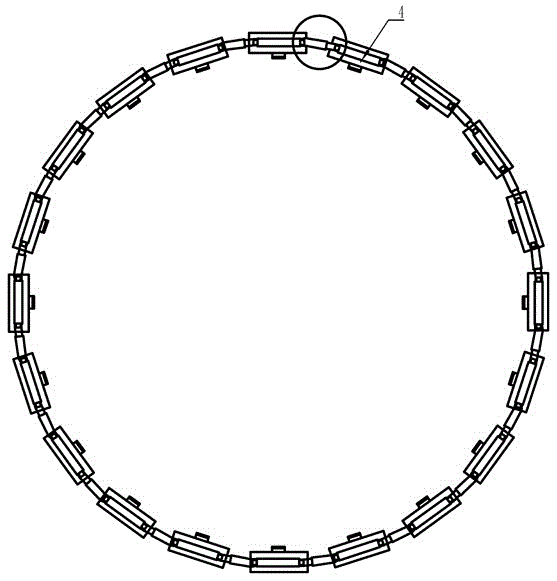

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: In the figure, 1-upper part, 101-rotating shaft, 2-lower part, 201-accommodating cavity, 202-hole, 203-top block , 3-Protruding strip, 301-Protruding block, 4-Side rail, 5-Basket bottom, 501-Side wall, 502-Fixing ring, 503-Fixer, 504-Groove, 6-Connecting cylinder, 7-Connecting rod .

[0017] Such as figure 1 As shown, the present invention includes a cylindrical basket bottom 5, a plurality of side rails 4 that are distributed circumferentially along the bottom of the basket 5 and spaced from each other, and support edges at the top of the side rails 4. The fixing ring 502 fixed at the bottom of the basket 5, such as figure 2 As shown, grooves 504 are arranged at intervals on the outer side of the fixing ring 502 .

[0018] Such as Figure 5 As shown, the side rail 4 is composed of a plurality of connection units; the connection un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com