Brick joint control tool used for fully laying carbon bricks on furnace bottom of blast furnace, and using method of brick joint control device

A technology for controlling tools and carbon bricks, applied in blast furnaces, blast furnace details, blast furnace parts and other directions, can solve the problems of high price of screw jacks, unsuitable fixation, waste of resources, etc., and achieve the effect of reducing construction costs, saving wood, and not being damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical features of the present invention more easily understood, the technical solutions of the present invention are described in detail below in conjunction with the accompanying drawings and embodiments:

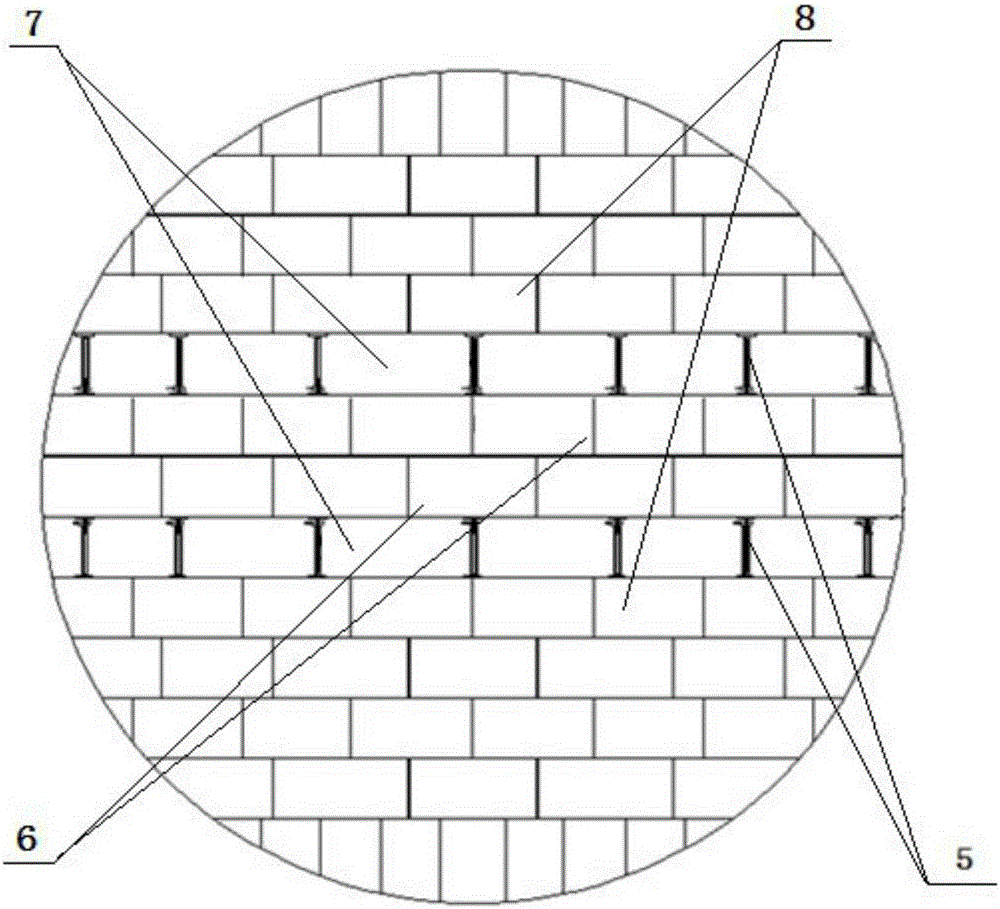

[0046] The brick joint control tool of the present invention comprises a screw wedge 4 and a screw support 5, which are respectively used to replace wooden wedges and screw jacks in traditional techniques.

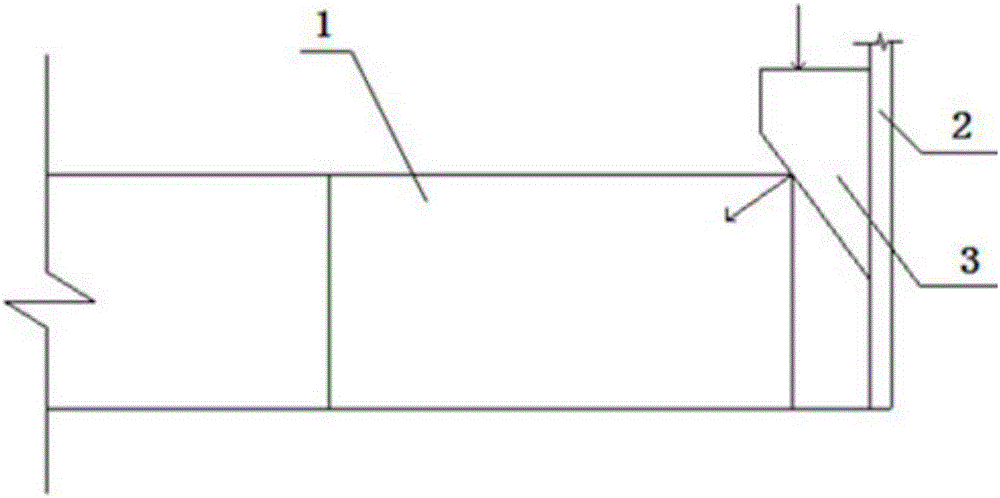

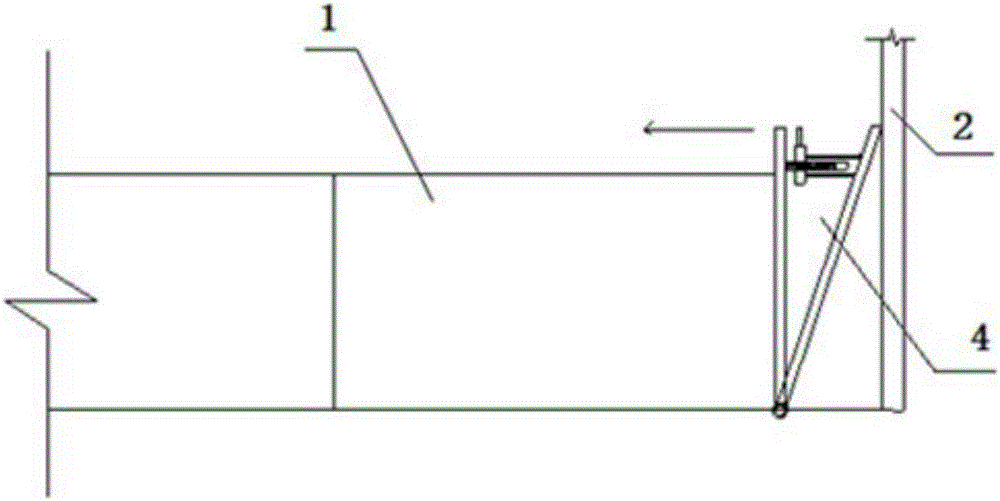

[0047] figure 2 It illustrates the situation that the present invention adopts the screw wedge 4 to control the brick gap.

[0048] see figure 2 , the screw wedge 4 in the present invention, like the wooden wedge 3 in the traditional craft, has an inclined surface that can be wedged into the brick seam, but the shape and size of this inclined surface can be adjusted arbitrarily according to needs, and this setting method can make the carbon brick evenly distribute the force On the entire side of the carbon brick 1, it is beneficial t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com