Tool and method for constructing composite anti-seepage underground continuous wall by using HDPE membranes

An underground diaphragm wall and composite anti-seepage technology, which is used in the construction of composite anti-seepage underground diaphragm walls using HDPE membranes, can solve the problems of poor resistance to chemical erosion, low strength, and difficulty in meeting the durability of diaphragm walls, and achieves high performance. Anti-seepage standard, extended lap length, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

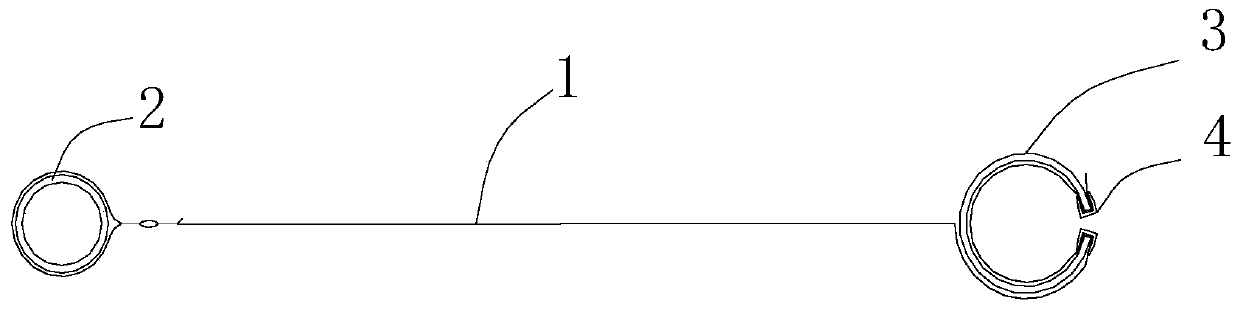

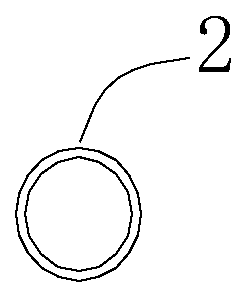

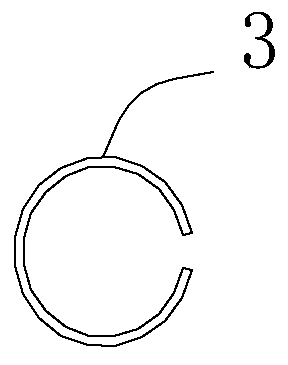

[0035] The invention provides a tool and a method for constructing a composite anti-seepage underground continuous wall by using HDPE diaphragms. During the construction of the self-setting mortar underground diaphragm wall, before the self-setting mortar has solidified, the invention can continuously install HDPE diaphragms with high corrosion resistance, low permeability and high stability in the self-setting mortar underground diaphragm wall to realize The perfect connection between HDPE membranes, the continuously laid HDPE membranes and self-setting mortar together form an underground anti-seepage curtain with low permeability and high reliability.

[0036] In the description of the present invention, it should be understood that terms such as "front" and "rear" herein indicating orientation or positional relationship are based on the orientation or positional relationship shown in the accompanying drawings, and are only for the convenience of describing the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com