Automatic clamping and conveying device for section steel

A handling device and clamping technology, which is applied in the direction of transmission, safety device, transportation and packaging, etc., can solve problems such as potential safety hazards, shaking, troublesome crane operation, etc., and achieve the effect of safe and fast handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

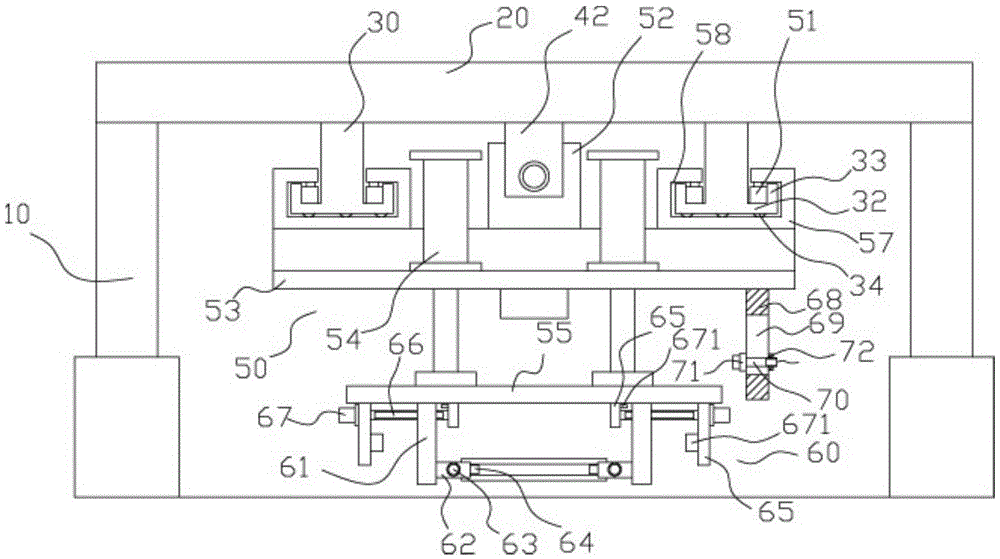

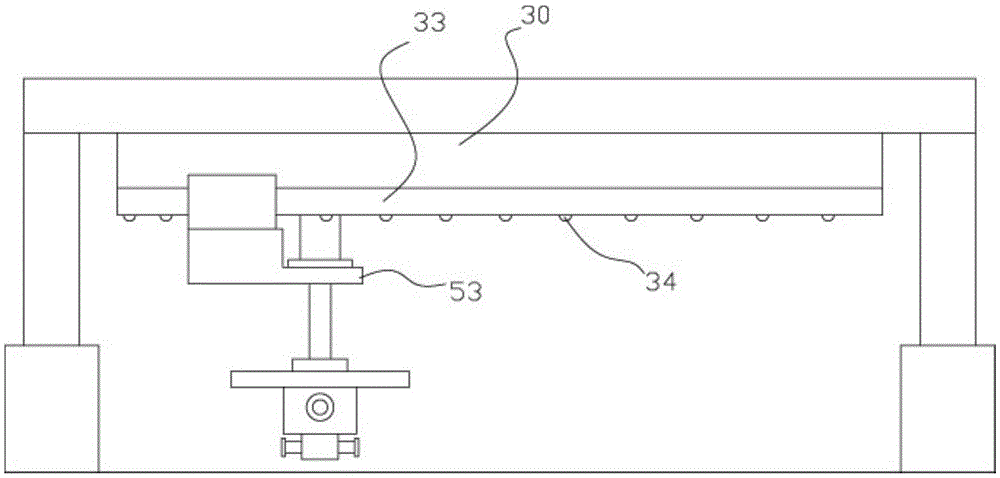

[0019] Example: see Figure 1 to Figure 5 As shown, a section steel automatic clamping and handling device includes a plurality of pillars 10, the tops of at least four pillars 10 are respectively fixed on the bottom surfaces of the four corners of the upper support plate 20, and the bottom ends of the pillars 10 are fixed on the ground , the left and right sides of the upper support plate 20 are fixed with two sliding track blocks 30, the upper support plate 20 between the two sliding track blocks 30 is provided with a transmission mechanism 40, and a sliding block 51 is installed on the mobile frame 50, and the sliding block 51 is on the sliding track block 30, and the middle part of the top surface of the mobile frame 50 is fixed with a connecting block 52, and the connecting block 52 is screwed in the transmission screw 41 of the transmission mechanism 40;

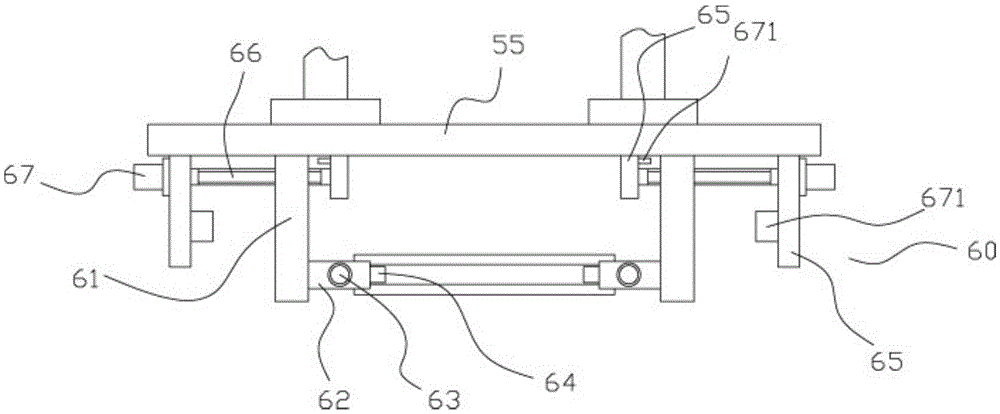

[0020] The front portion of the mobile frame 50 has an extension plate 53, and at least two push cylinders 54 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com