Method for removing dirt on surface of trash rack in narrow trash rack hole

A trash rack and orifice technology, applied to mechanically driven excavators/dredgers, etc., can solve problems such as low efficiency, shutdown cleaning, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

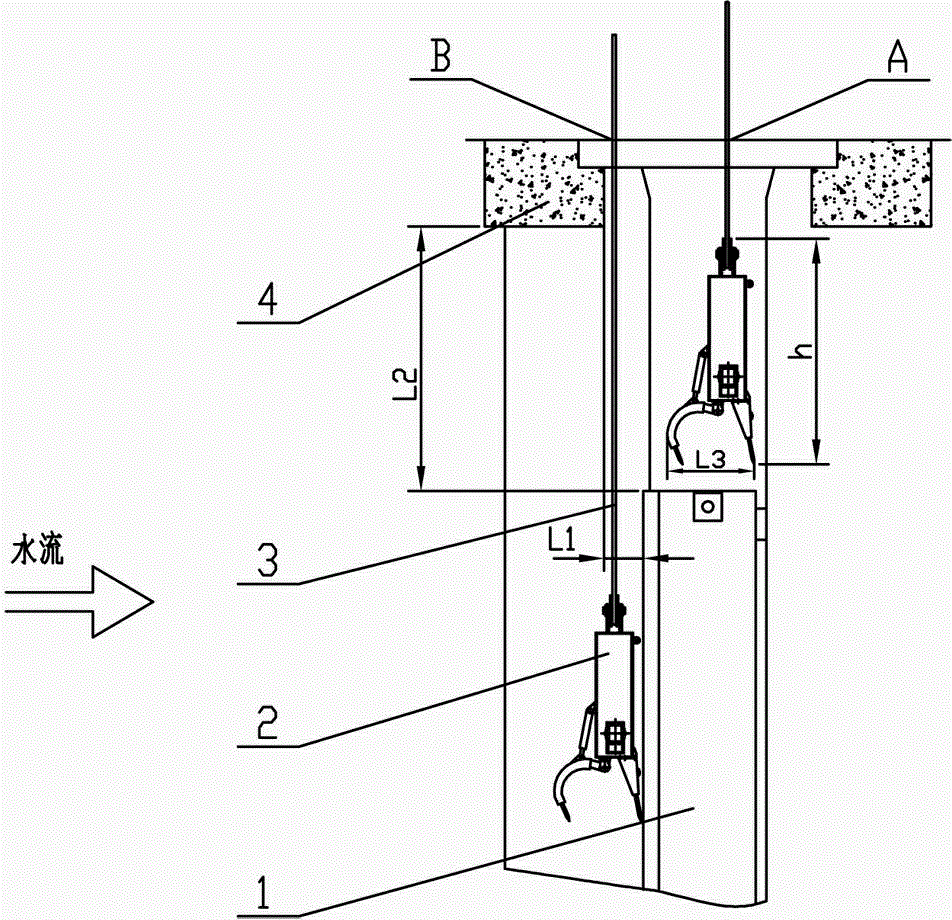

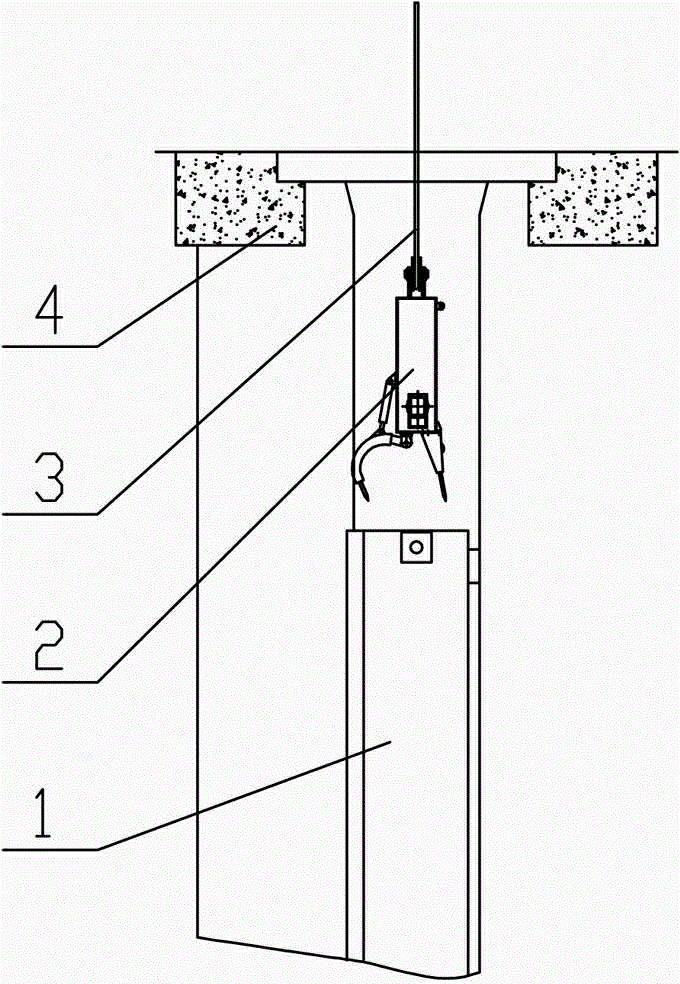

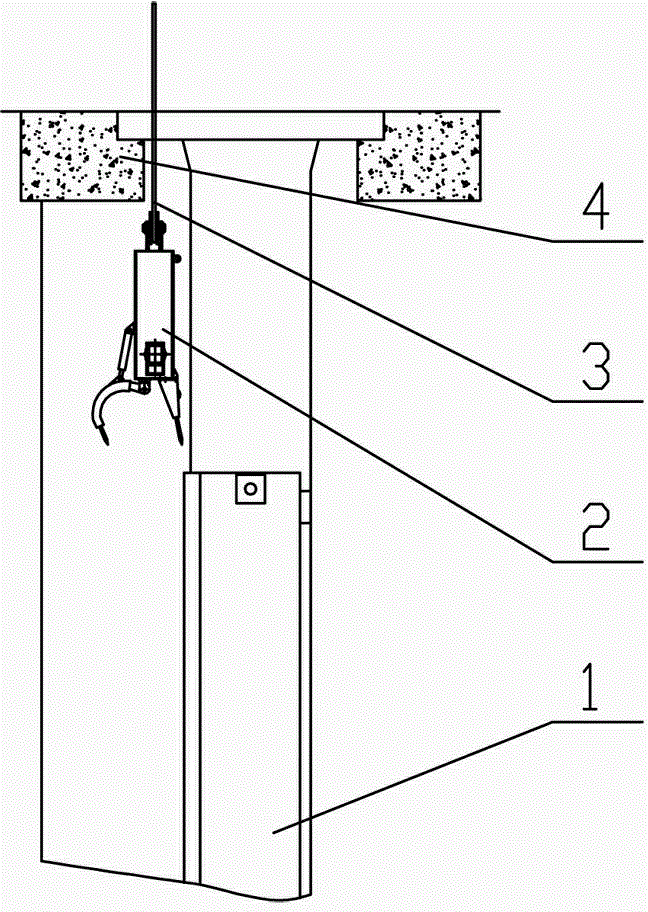

[0032] figure 1 It is an explanatory diagram for the applicable occasions of the method for removing dirt from the trash rack surface in the narrow trash rack aperture of the present invention, in which the horizontal distance from the grid surface of the trash rack 1 to the hydraulic structure 4 at the aperture is L1, the vertical distance from the top surface of the trash rack 1 to the bottom surface of the orifice hydraulic structure 4 is L2; the width of the cleaning grab 2 in the figure is L3, and the height of the cleaning grab 2 is h. For the orifice of this narrow trash rack, since the horizontal distance L1 from the grid surface of the trash rack to the hydraulic structure at the orifice is generally smaller than the width L3 of the cleaning grab, the cleaning grab cannot The method is to directly go down to the grid surface of the trash rack to carry out the cleaning work. But if the height dimension h of this cleaning bucket is less than the top surface of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com