A system and method for measuring thin-layer water flow rolling waves based on pressure sensors

A pressure sensor and thin-layer water flow technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of different measurement results, difficulty in ensuring measurement accuracy, and poor stability, so as to improve observation efficiency and save energy. The effect of human and precise data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

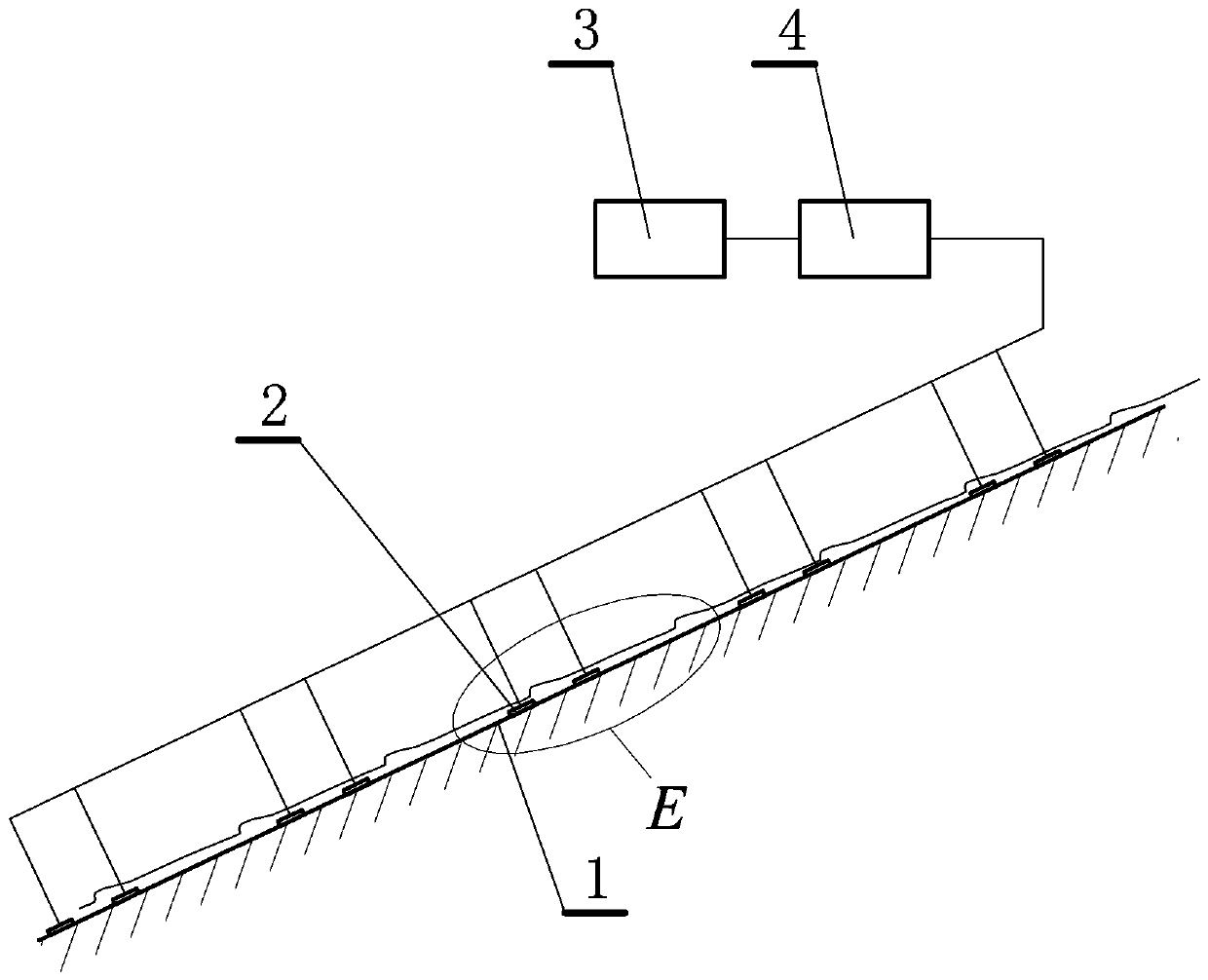

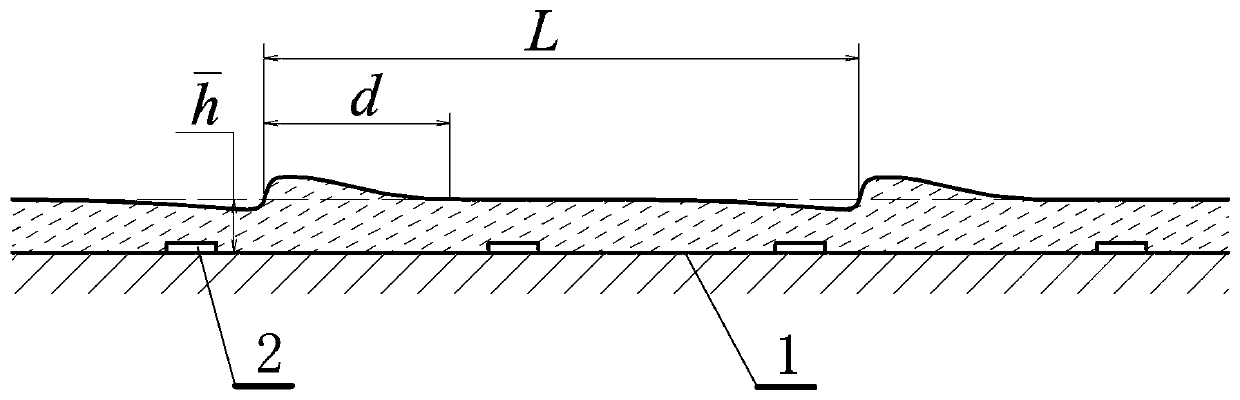

[0033] This embodiment is a thin-layer water flow rolling wave measurement system based on a pressure sensor, such as figure 1 shown. This embodiment includes: a plurality of pressure rolling wave sensors 2 arranged on a flat slope 1, and the pressure rolling wave sensors are arranged in such a way: the plurality of pressure rolling wave sensors are divided into multiple groups, each group has two pressure rolling wave sensors, each group of pressure rolling wave sensors is arranged in a line along the water flow direction, and the distance between each group of pressure rolling wave sensors is smaller than the distance between the measured rolling waves and greater than the width of the measured rolling waves; Two pressure rolling wave sensors are arranged in a line along the water flow direction, and the distance between the two pressure rolling wave sensors is greater than the distance between the peak and trough of the measured rolling wave. The pressure rolling wave senso...

Embodiment 2

[0046] This embodiment is an improvement of the first embodiment, and is a refinement of the embodiment about the pressure roll sensor. The pressure rolling wave sensor described in this embodiment is: a metal resistance strain gauge or a semiconductor strain gauge.

[0047] These two strain gauges have their own advantages. Metal resistance strain gauges are suitable for accurately measuring relatively thin water flows, while semiconductor strain gauges are suitable for measuring relatively thicker water flows.

Embodiment 3

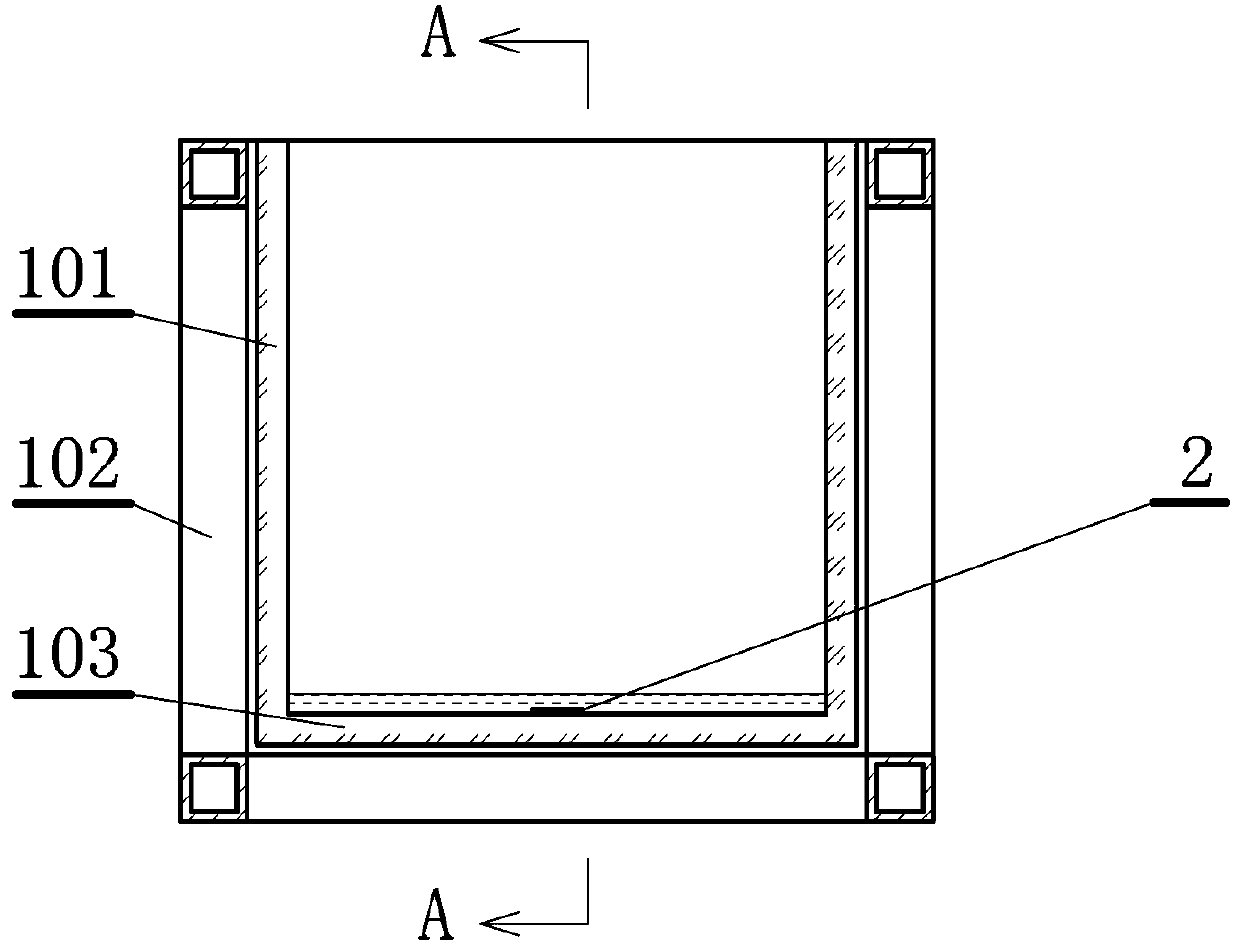

[0049] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the slope. The slope described in this embodiment is the bottom of the test tank, and the test tank includes: the sides 101 on which the fixing frame is installed and the bottom 103 connected with the sides of the tank. The side and the bottom of the tank are arranged on the steel structure frame 102. One end of the water tank is provided with a water inlet 106, and the other end is provided with a water outlet 109. The water outlet is connected to the circulating pool 108 by pipes, and the water inlet is connected to the water pump 107. The pipes of the circulating pool are connected, a hinge 104 is set on one side of the water outlet of the steel structure frame, and a lifting mechanism 105 is set on the other side, such as image 3 , 4 shown.

[0050] This embodiment is a water tank that can be installed in a laboratory. The steel frame supports the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com