Method and system utilizing Excel format data to process welding performance data

A technology of welding performance and format data, which is applied in the fields of electrical digital data processing, natural language data processing, and special data processing applications, etc., which can solve the difficulty of unifying and using welding raw data and performance data, scattered welding test data, and inconvenient use and other problems, to achieve the effect of convenient and quick arrangement of records, optimization of welding parameters, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

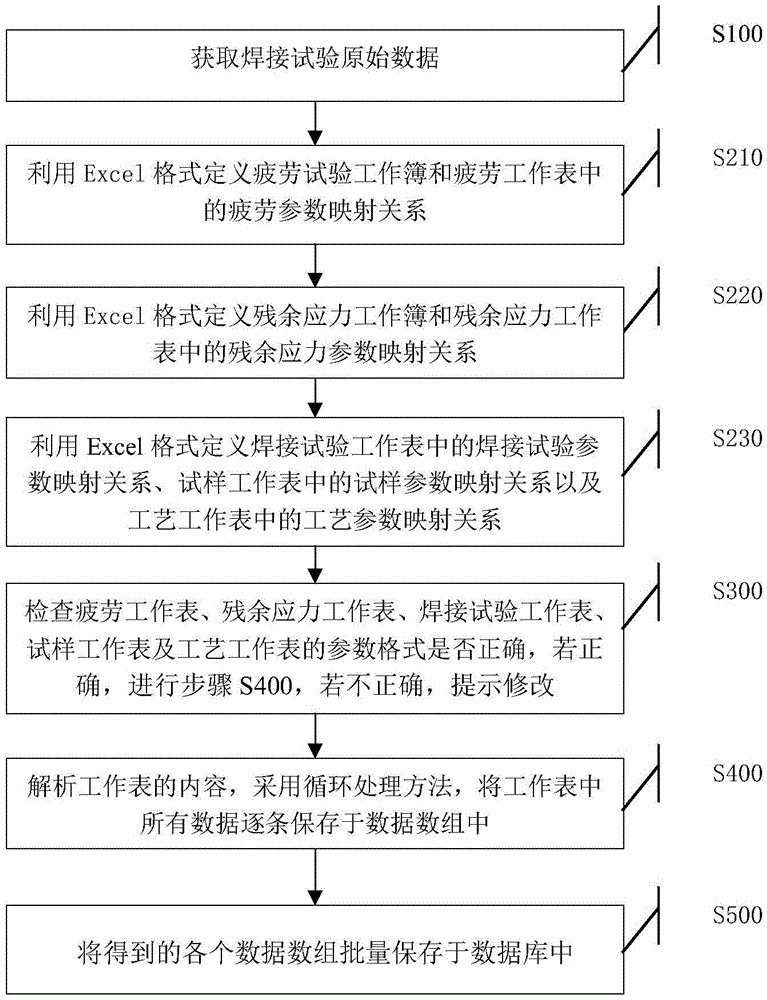

[0035] figure 1 Shown, a kind of embodiment of the method of the present invention is: a kind of method utilizing Excel format data processing welding performance data, comprises the following steps:

[0036] S100. Obtain the original data of the welding test, including welding test data, welding test sample data, process data, and fatigue test data and residual stress test data of the sample after welding;

[0037] S210. According to the raw data of the welding test, define a fatigue test workbook in Excel format, the fatigue test workbook includes a fatigue worksheet, a welding test worksheet, a sample worksheet, and a process worksheet; then according to the fatigue test Data, use the Excel format to define the fatigue performance parameter mapping relationship in the fatigue worksheet;

[0038] S220. According to the original data of the welding test, define a residual stress workbook in Excel format, the residual stress workbook includes a residual stress worksheet, a we...

Embodiment 2

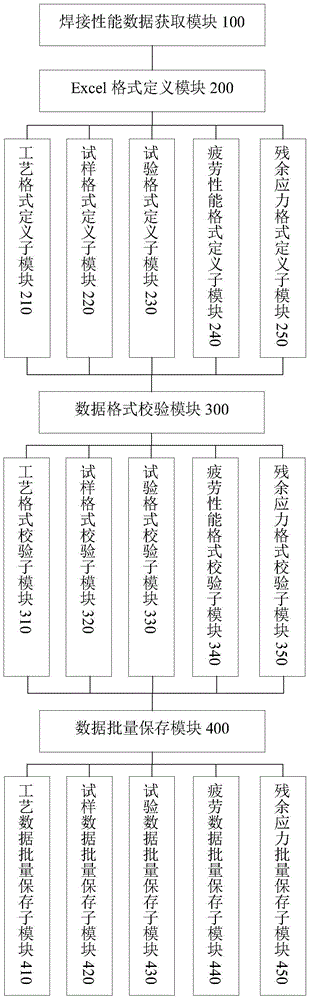

[0049] figure 2 As shown, a specific embodiment of the system of the present invention is: a system for processing welding performance data using Excel format data, including:

[0050] The welding raw data acquisition module 100 is used to obtain the raw data of the welding test, including welding test data, welding test sample data, process data, fatigue test data and residual stress test data of the sample after welding;

[0051] The Excel format definition module 200 is used to define the mapping relationship between Excel cells and attributes according to the welding test data, and specifically includes the following submodules: the process format definition submodule 210 is used to define the relationship between the Excel format and each process parameter in the process data The mapping relation between, obtains craft worksheet; Sample format definition submodule 220, is used for defining the mapping relation between each sample parameter in Excel format and sample data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com