Intelligent storage and automatic distribution system of pharmacy

A technology of intelligent warehousing and automatic distribution, applied in the field of control systems, can solve problems such as complex environments, no standards, and heavy workload, and achieve the effects of reducing costs, saving space, and solving complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

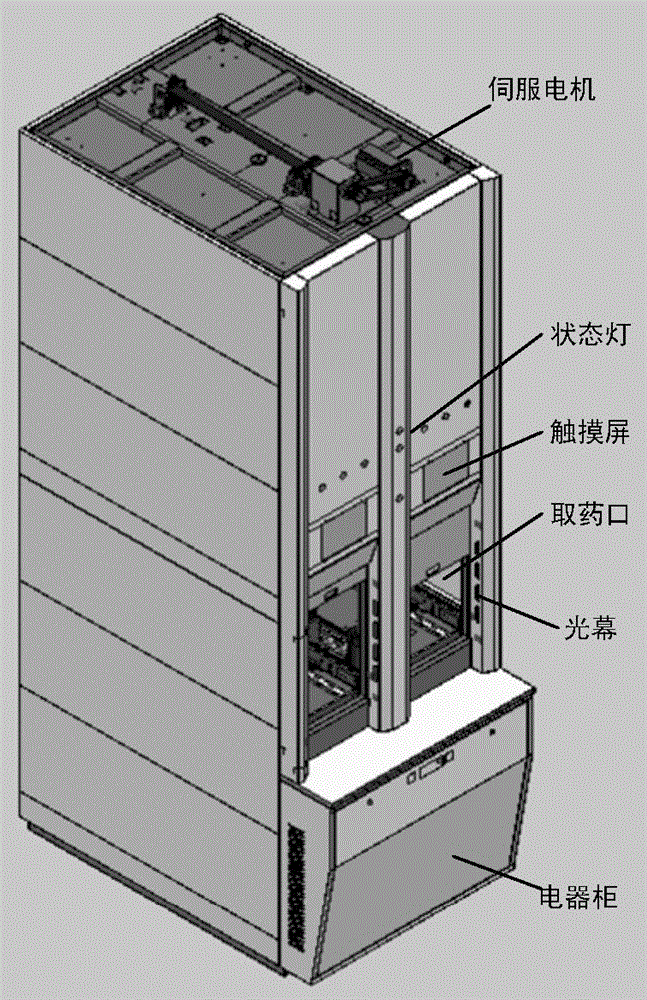

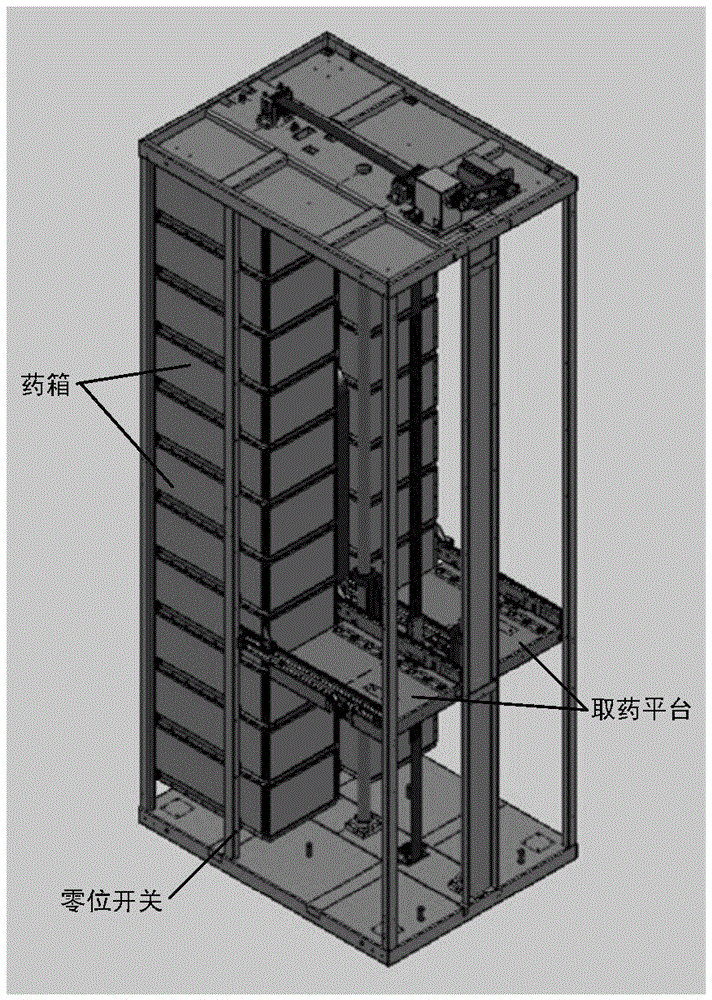

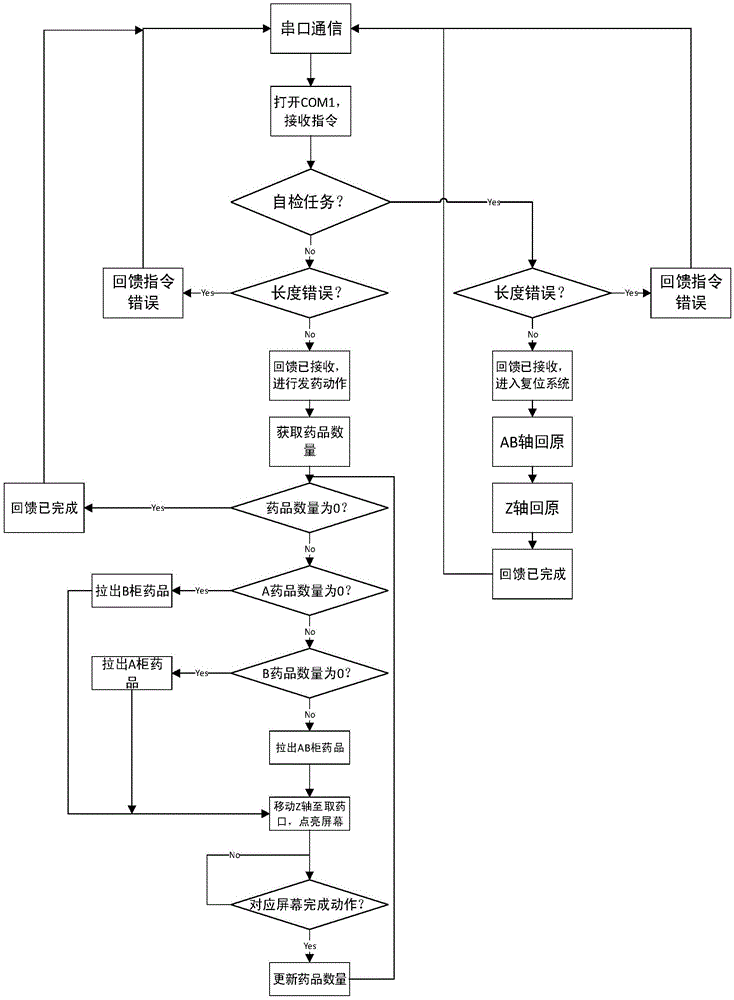

[0025] The intelligent storage and automatic distribution system of the pharmacy of the present invention includes a data processing module, a communication module and a mechanical execution module. The data processing module of the present invention is a host computer main control system written in C language, which analyzes and extracts the prescriptions in the database in combination with the drug storage distribution table of the unit to generate the instructions of the corresponding unit, and communicates with the lower computer ( PLC) to communicate. The main controller of the mechanical execution module is Panasonic PLC (FPX-C40T) and expands COM5 for communication, and the slave controller is divided into servo motor driver and man-machine interface control panel. All medicines are evenly stored in multiple units according to the designed warehouse distribution table, and the main control unit and all units are connected in the same network domain through a switch, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com