Gas discharge lamp and use thereof

A gas discharge lamp, gas technology, applied in the field of deuterium lamps, can solve the problem of reducing lamp life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

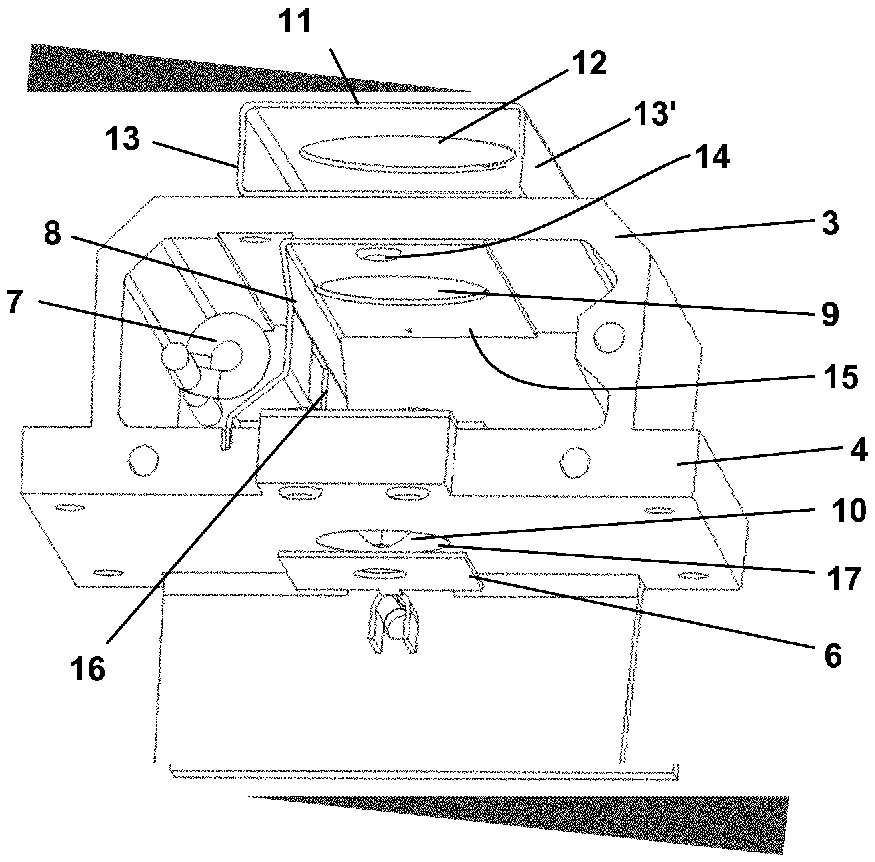

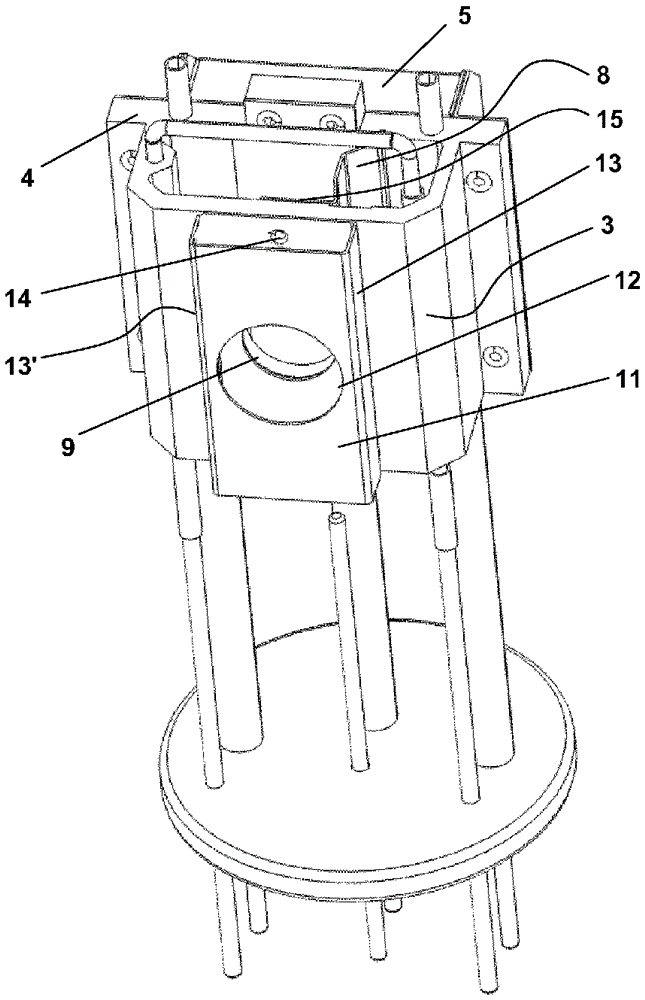

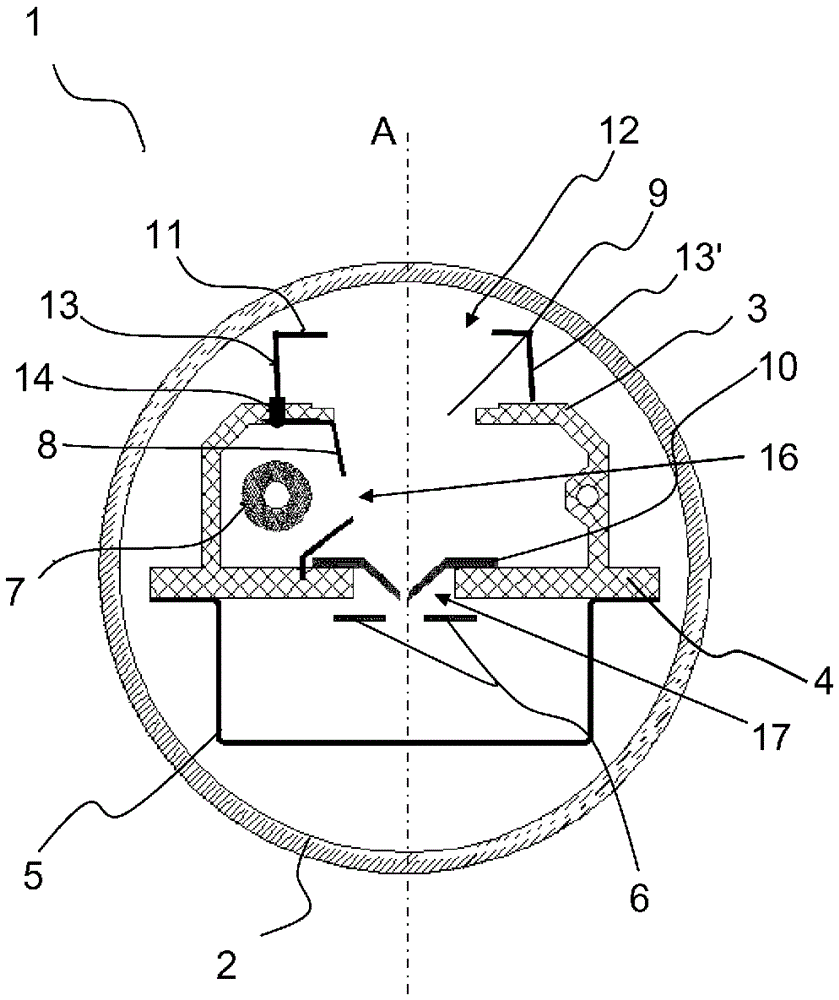

[0031] exist figure 1 , schematically shows a cross-section of a deuterium lamp 1 along the optical axis A. The lamp 1 has a bulb 2 and a two-part housing consisting of a front housing part 3 with a housing intermediate wall 4 and a rear housing part 5 which The housing part is made of ceramic, in this case aluminum oxide, and the rear housing part is made of metal. The bulb 2 is filled with a gas, here deuterium. The anode 6 is located in the rear housing part 5 . A cathode 7 and a cathode shielding window 8 made of nickel sheet metal are arranged in the front housing part 3 . Furthermore, the front housing part 3 has a light exit window 9 which is situated opposite the anode 6 and forms with it the optical axis A of the gas discharge lamp. The cathode shielding window 8 has an opening 16 in the direction of the optical axis A. As shown in FIG. When the lamp 1 is in operation, a discharge is formed between the cathode 7 and the anode 6, which discharge provides a contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com