Shirt fly front structure and making method of shirt fly front

A manufacturing method and a technology of plackets, applied in the field of clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

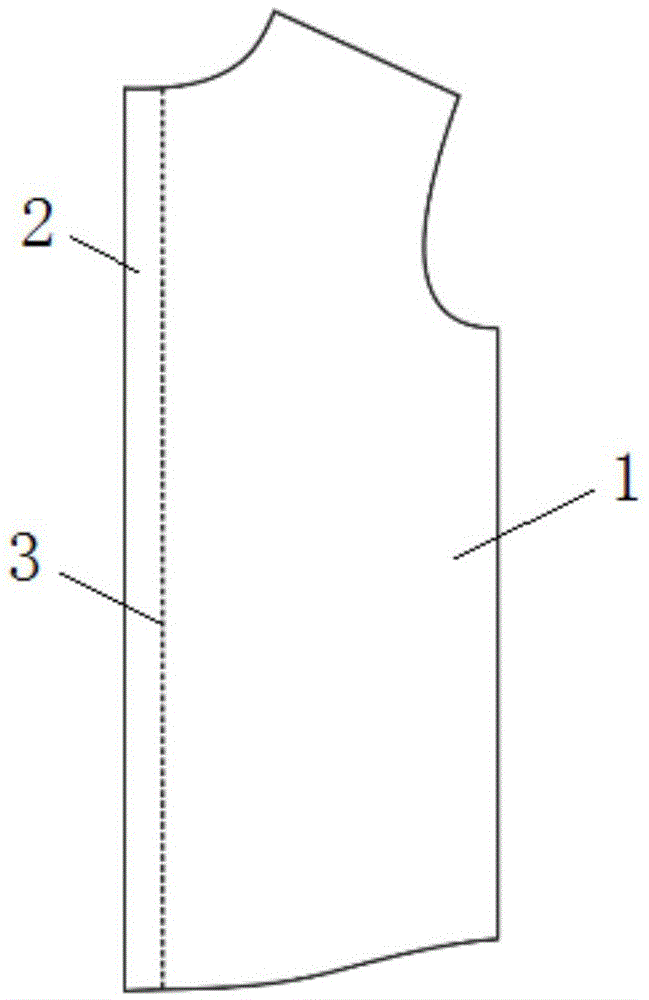

[0035] figure 1 It is a schematic diagram of the front structure of the present invention; as figure 1 As shown, a shirt fly structure provided by the present invention includes a front panel and a double-layer flyway sewn on the front panel, and the double-layer flyway includes an outer layer flyer 2 and an inner layer flyer 5 . In this embodiment, the double-layer placket is arranged on the left front piece of the shirt, and only the suture line 3 and the outer placket 2 can be seen on the front side 1 of the left front piece, and the appearance is neat and tidy.

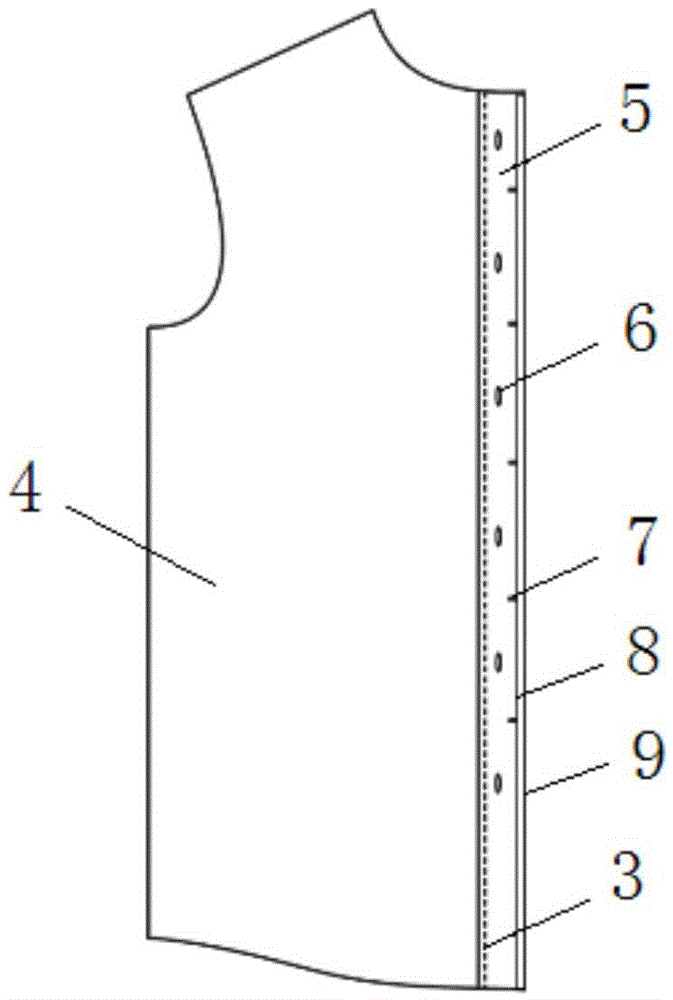

[0036] figure 2 It is a schematic view of the reverse structure of the present invention; as figure 2 As shown, the inner layer placket 5 is covered by the outer placket 2, and is hidden on the reverse side 4 of the left front piece. The outer end of the outer layer fly 2 is an outer layer fly stop 9, the outer end of the inner layer fly 5 is an inner layer fly stop 8, and the inner layer fly 5 is provided al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com