Automated shape correcting device for wind driven generator blades

A wind turbine and blade technology is applied in the field of wind turbine blade automatic shaping devices, which can solve the problems of backward technology and low accuracy, and achieve the effects of long service life, not easy to collide, and good size control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

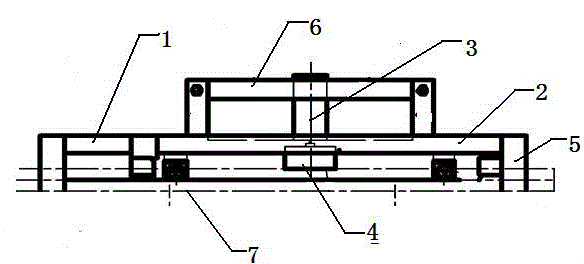

[0012] This embodiment provides an automatic blade modification device for a wind power generator, characterized in that: the automatic blade modification device for a wind power generator includes a slideway (1), a frame (2), a lifting device (3), Milling device (4), steel frame (5), pressure plate (6), blade (7);

[0013] Among them: the slideway (1) is fixed on the steel frame (5) of the mold, the frame (2) is slidingly fitted on the slideway (1), the lifting device (3) and the milling device (4) are both installed on the machine frame (2), and the lifting device (3) is connected with the milling device (4) to drive it up and down. The uppermost end of the device is provided with a pressure plate (6), which is set on the frame (2) and covered by the milling device. on the device (4).

[0014] The lifting device (3) is a hydraulic oil cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com