Natural laminar flow aerofoil profile with high lift

A laminar flow wing and high-lift technology, applied in wing design and aircraft field, can solve problems such as flow separation, large lift coefficient, and small laminar flow area on the airfoil surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

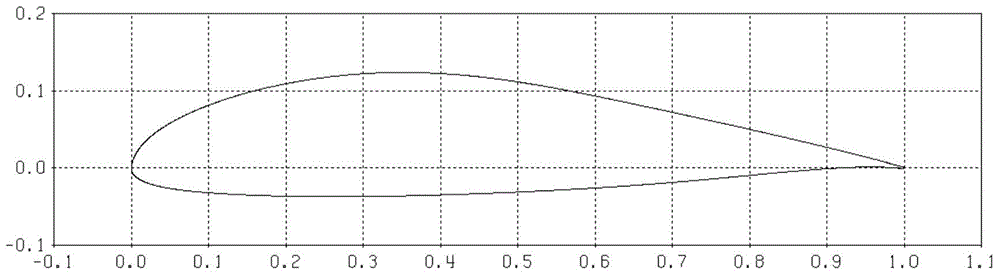

[0017] A high-lift natural laminar flow airfoil is characterized in that the airfoil has a streamlined structure with a blunt leading edge and a weakly reversed trailing edge, and the surface curve of the airfoil is geometrically single-convex without obvious curvature inflection.

[0018] High-lift natural laminar flow airfoil, its geometric coordinates Table 1 reflects, and refer to the attached figure 1 :

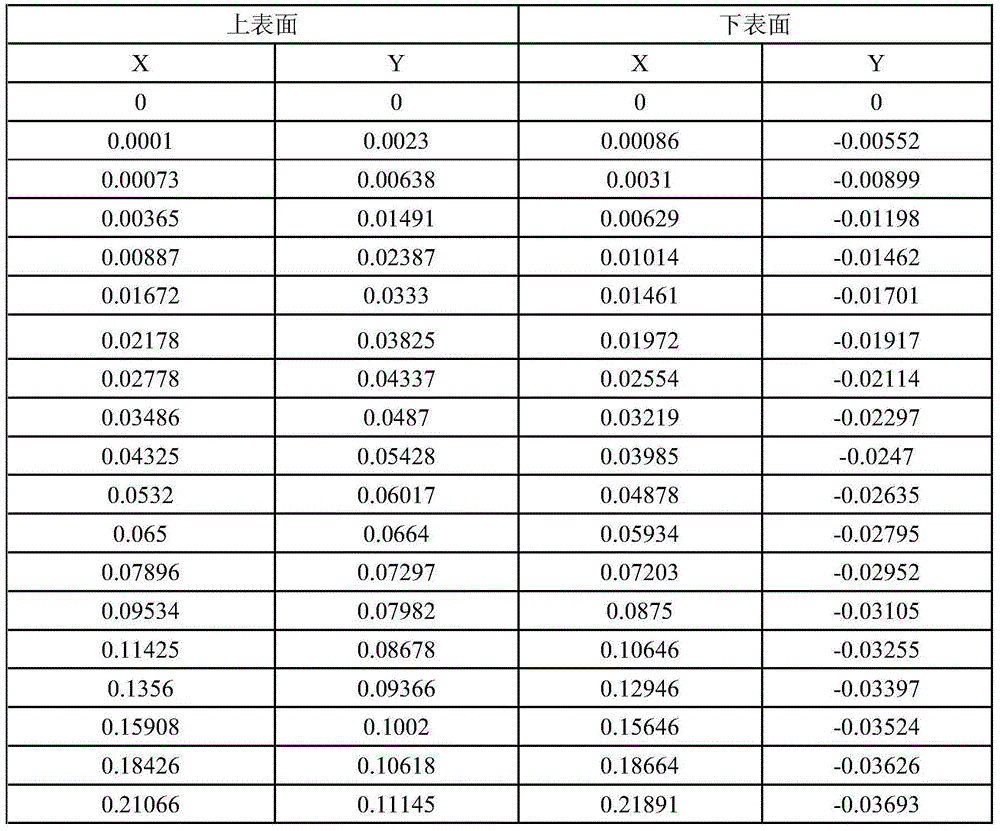

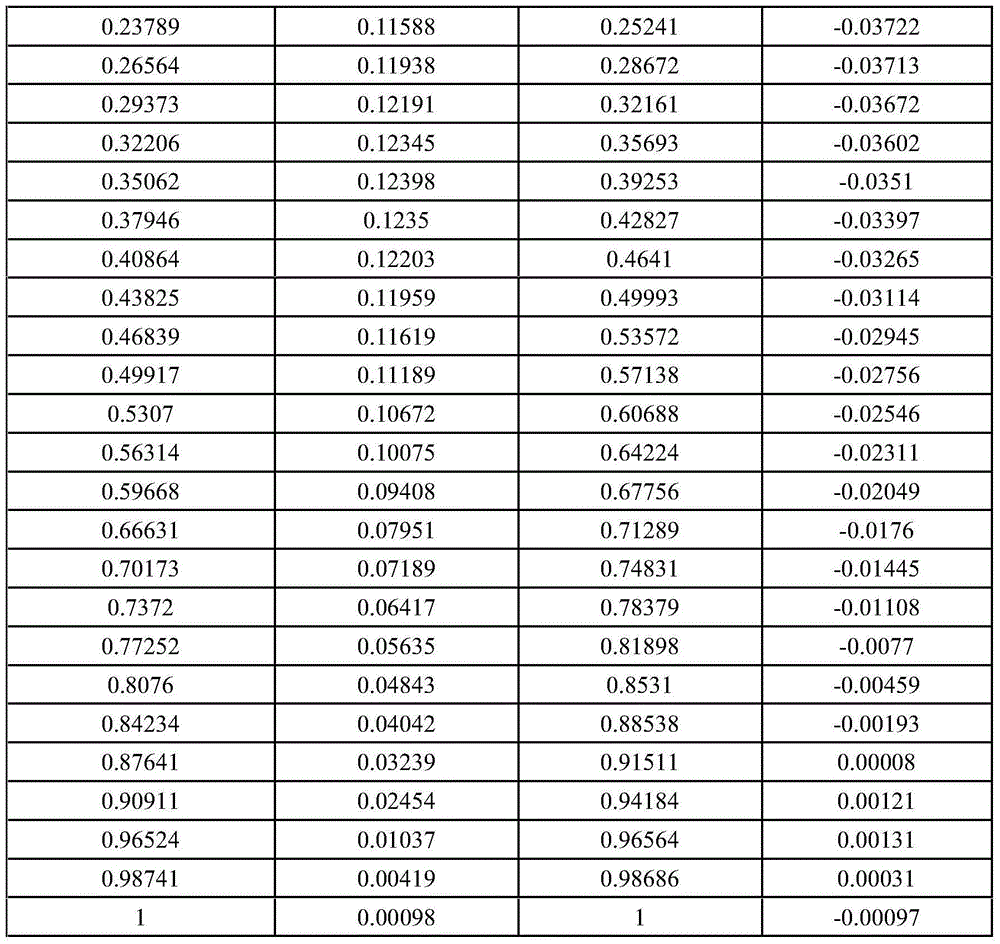

[0019] Table 1

[0020]

[0021]

[0022] The airfoil of the present invention, under free transition conditions, the lift-to-drag ratio corresponding to the design lift coefficient (CL=1.1) is about 125, and the maximum lift-to-drag ratio is about 130; while the conventional turbulent airfoil is at the design lift coefficient (CL=1.1) The lift-to-drag ratio is only about 60.

[0023] The design lift coefficient of the conventional natural laminar flow airfoil is small (generally less than 0.5). In the state of high lift coefficient, the laminar flow region and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com