Jet flap lift augmentation connecting wing system and aircraft applying same

A technology for jet flaps and connecting wings, applied in the field of aircraft, can solve the problems of reducing the air pressure on the lower wing surface, high noise and vibration, and high structural requirements, and achieve speed and temperature reduction, erosion and ablation reduction, and increase in lift. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

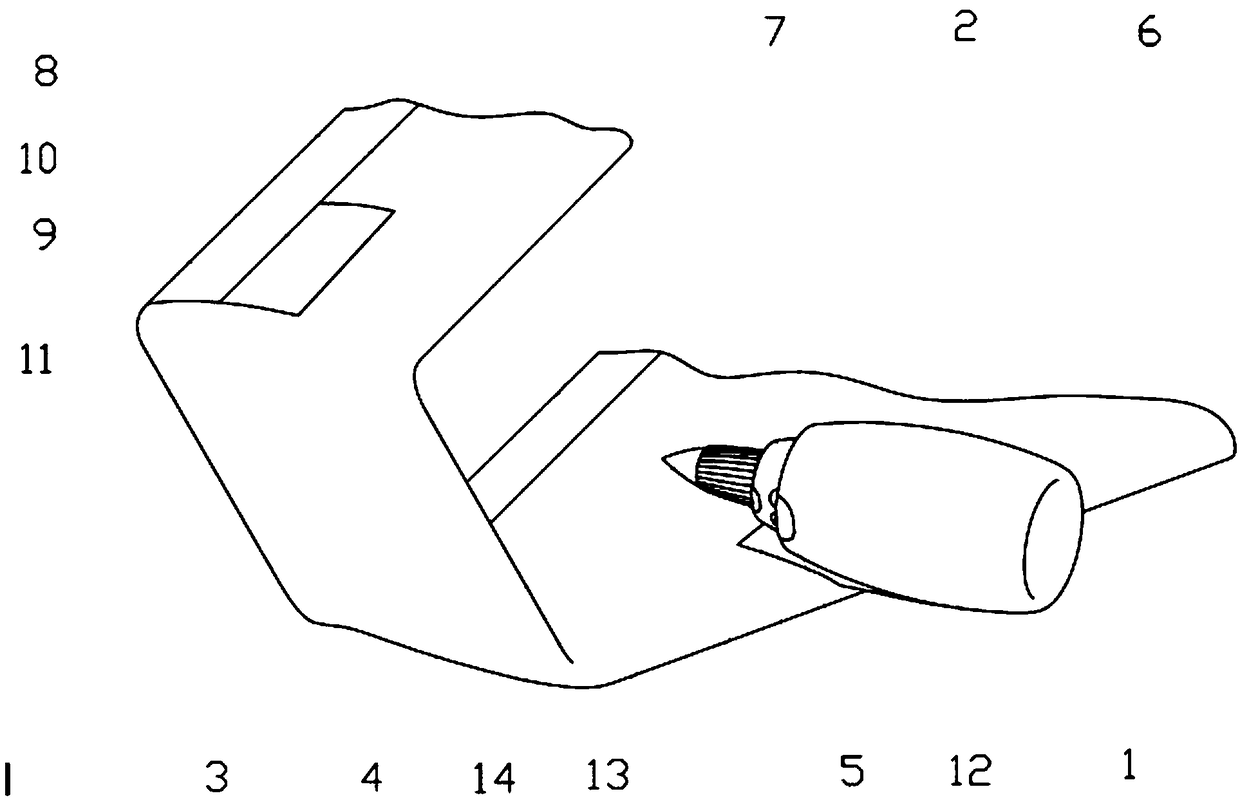

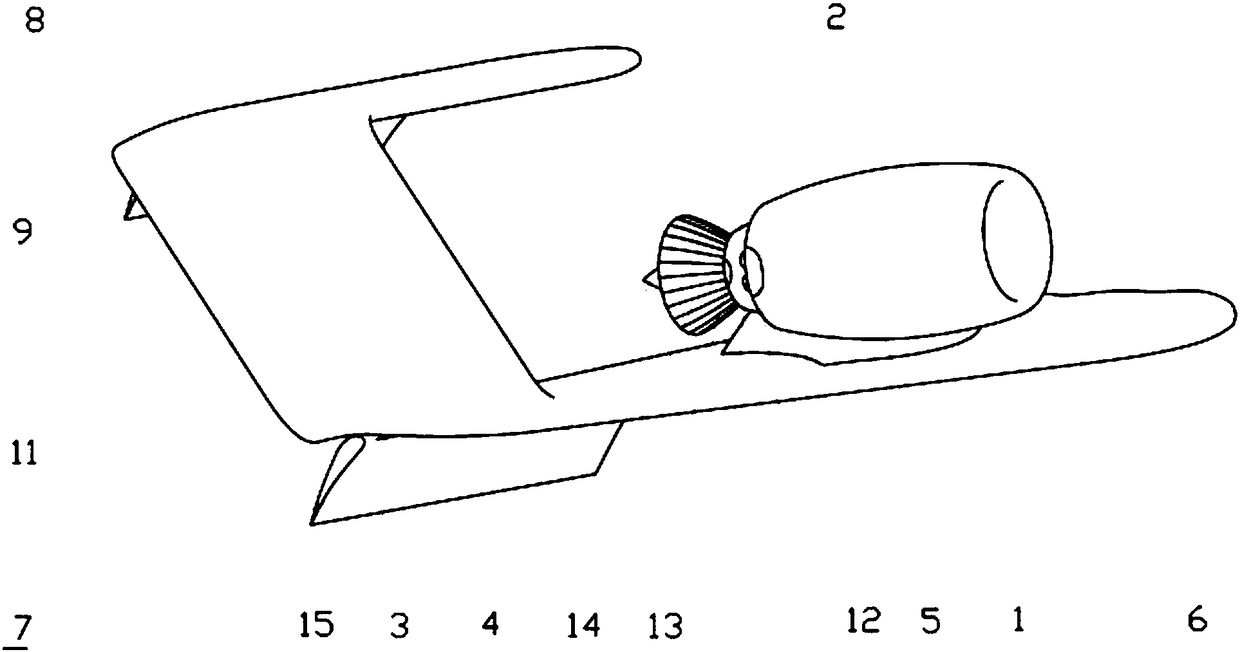

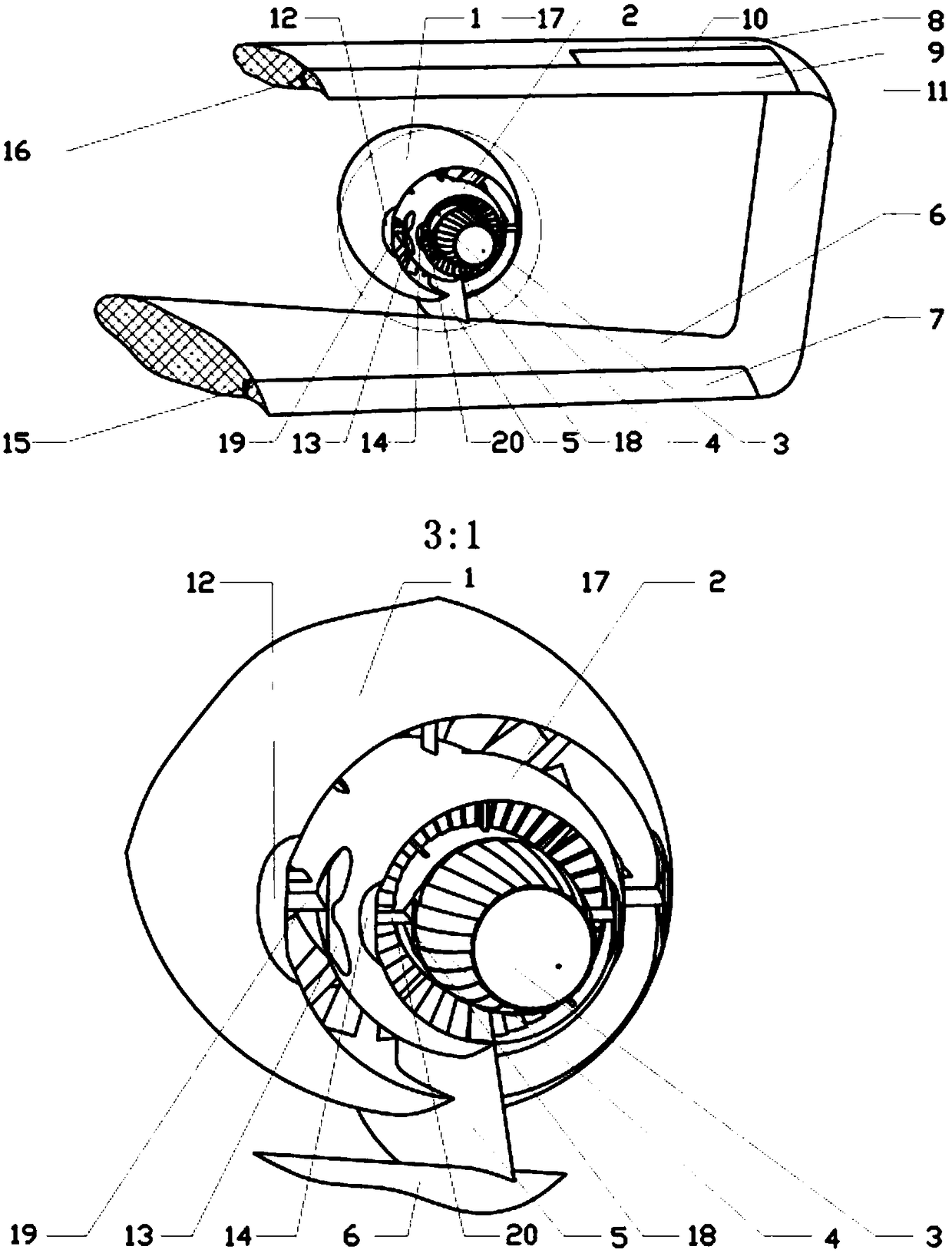

[0022] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the jet-flap increase-lift connecting wing system of the present invention comprises a turbofan engine, a wing, a pylon 5 connecting the turbofan engine and the wing, and the turbofan engine has The turbine shaft rectifying cone 3, the wing has trailing edge flaps, the turbine shaft rectifying cone 3 is extended backward for a certain length, and the multi-fish scale type convergent and diffusing nozzle 4 is arranged on it, and there is one on the left and right sides of the outer duct nozzle. For the airflow convergence and diffusion device for the jet flow in the external channel, there is also an airflow convergence and diffusion device for the jet flow in the inner channel on the left and right sides of the nozzle of the inner channel. The airflow converging and diffusing device for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com