Automatic discharge system for powder

An automatic discharge and powder technology, applied in the direction of powder material distribution, etc., can solve the problems of high labor cost, low efficiency, difficult maintenance, etc., to solve the problem of low labor efficiency, high work intensity and fast sorting speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

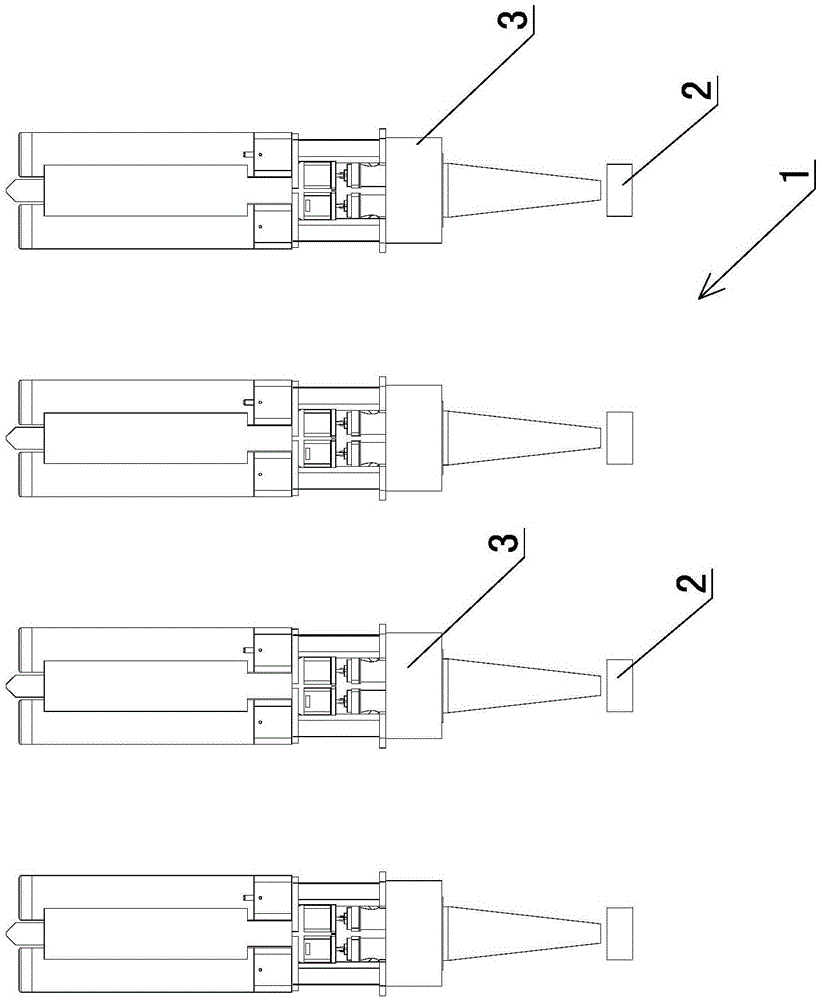

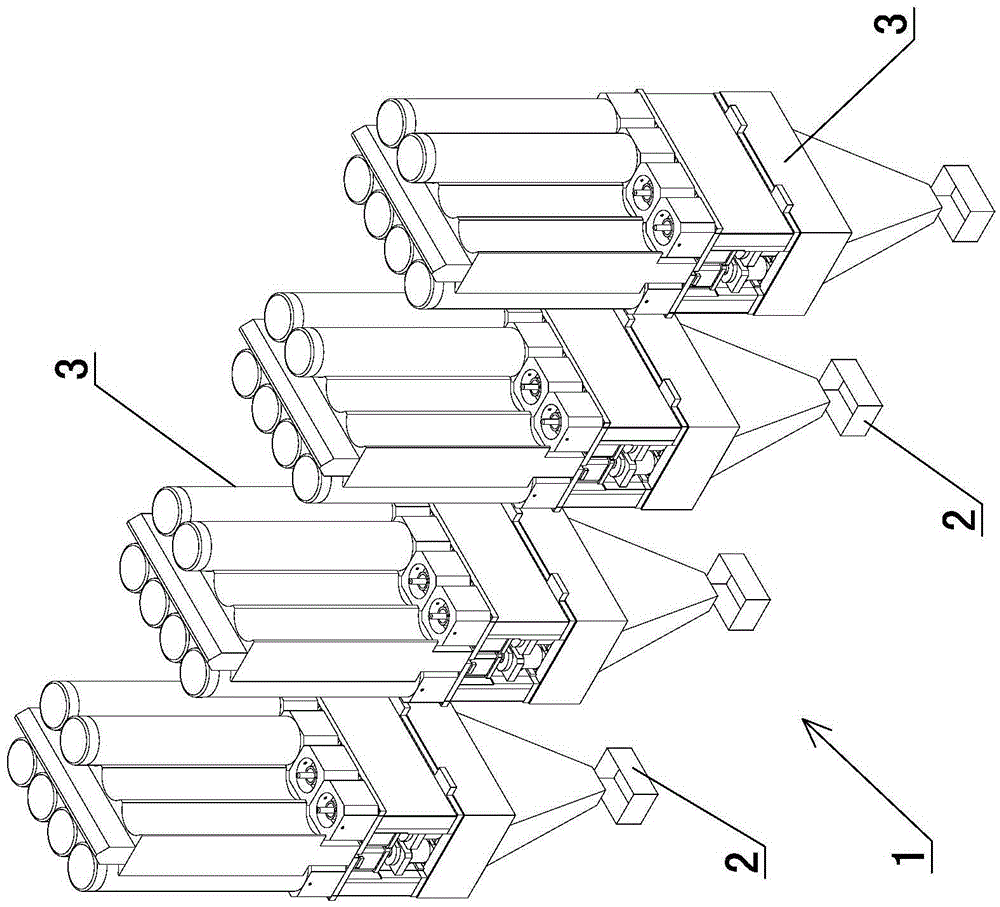

[0048] Example: see attached figure 1 , 2 As shown, an automatic powder discharge system 1 is used for powder automatic quantitative sorting equipment (not shown in the figure), and the powder does not include traditional Chinese medicine; the equipment includes a frame, and the automatic discharge system 1 is fixed relative to the frame; the automatic discharging system 1 includes multiple groups of discharging units 3, and a receiving container 2 arranged vertically below each discharging unit 3.

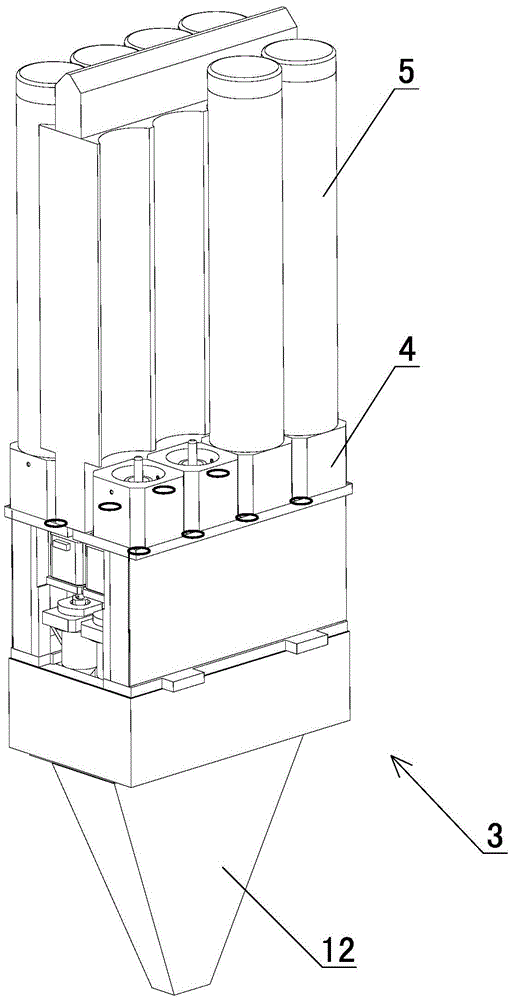

[0049] like image 3 As shown, the discharge unit 3 includes eight sets of discharge devices 4 (the number can be increased or decreased according to the equipment occupation space, and two of the storage tanks 5 are hidden in the figure).

[0050] like Figure 4~6 As shown, each of the discharge devices 4 includes a storage tank 5 vertically arranged from top to bottom, a feeding mechanism and a weighing mechanism; the bottom of the storage tank 5 is a discharge port 6; The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com