Passenger conveying device

A technology of passenger conveying and driving device, which is applied in transportation and packaging, escalators, etc., to reduce the number of parts and improve the set-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as Figure 4 As shown, the passenger conveying device, such as an escalator, includes: steps 1, which are connected endlessly and move between the upper and lower openings; step driving machine 3, which is arranged in the upper mechanical room 2; driving sprocket 4 , the driving sprocket 4 is driven by the step driving machine 3 ; and the step chain 5 is wound and suspended on the driving sprocket 4 . In addition, the step driving device A is formed by using the step driving machine 3, the driving sprocket 4 and the step chain 5. The power of the motor of the step driving machine 3 is transmitted to the step 1 through the driving sprocket 4 and the step chain 5, and the step 1 is at the upper and lower openings. to move between.

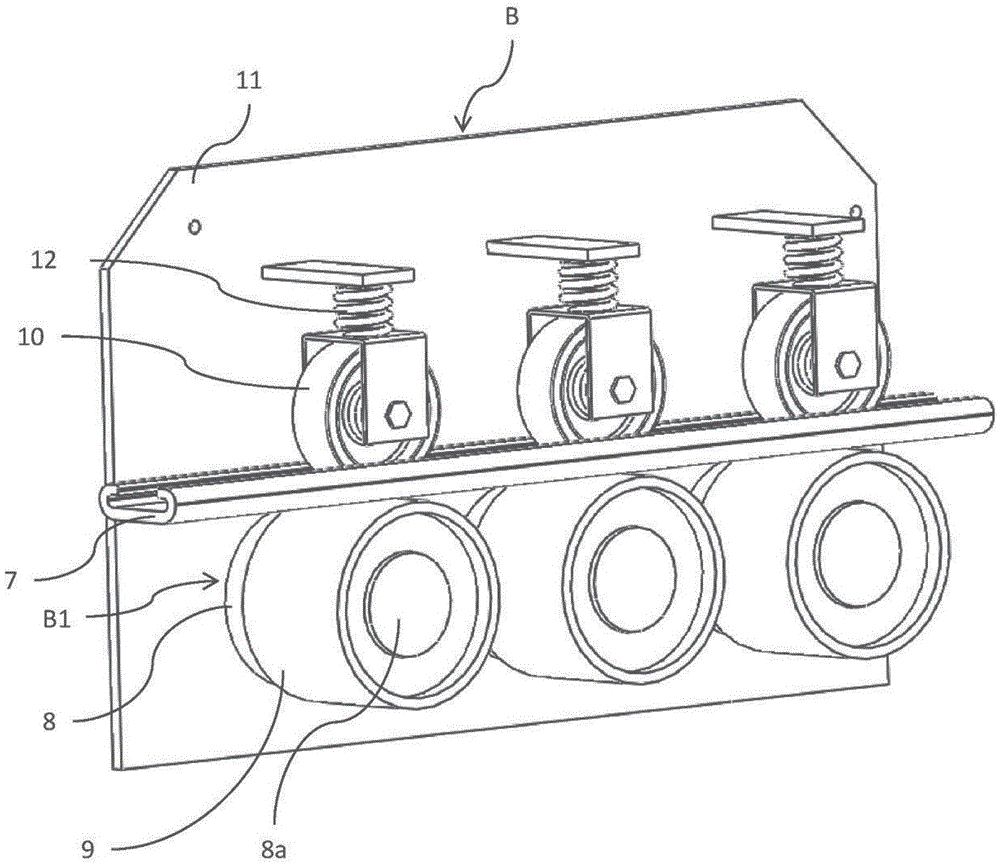

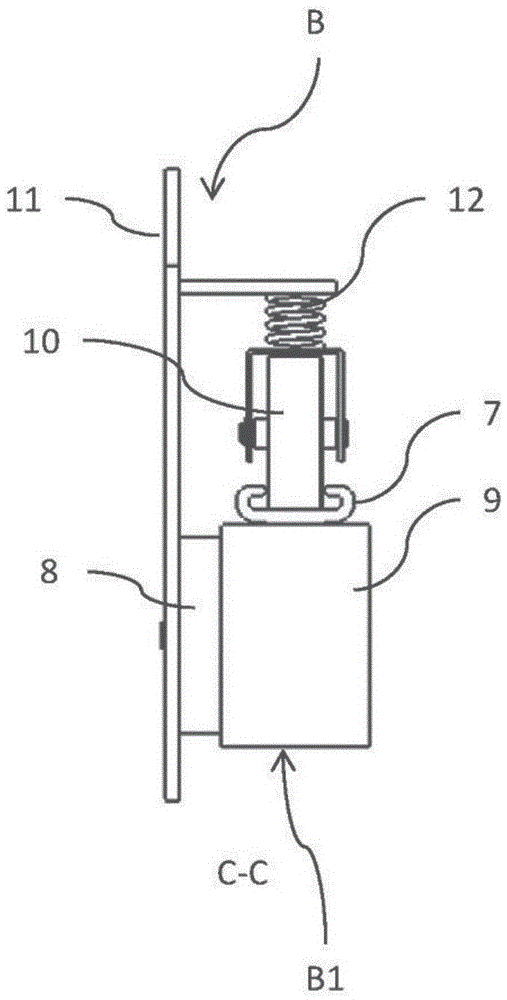

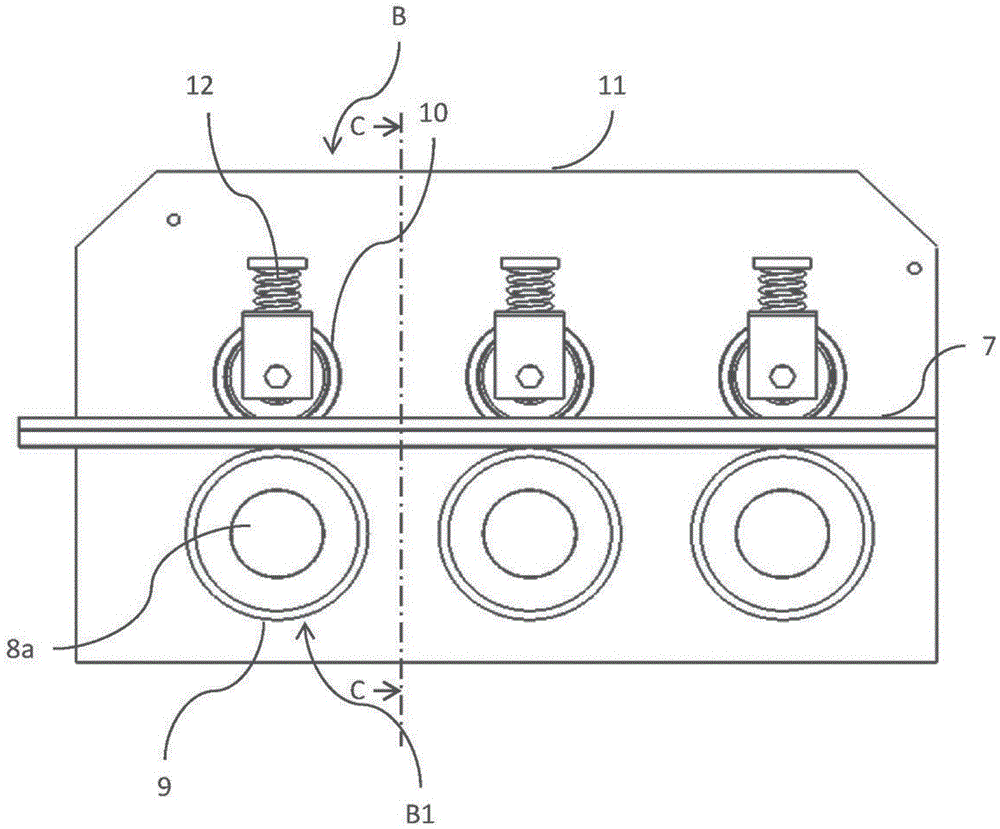

[0025] In addition, it includes a handrail 6 and a handrail 7 , the handrail 6 is erected on the side along the traveling direction of the steps 1 , and the handrail 7 is supported by the handrail 6 and moves in the same direction as the...

Embodiment 2

[0033] Here, based on Figure 5 to Figure 8 , Embodiment 2 of the passenger conveying apparatus according to the present invention will be described. In addition, the same code|symbol is attached|subjected to the structure similar to the structure shown in said Embodiment 1.

[0034] In Embodiment 2, the difference from the above-mentioned Embodiment 1 is that, as Figure 5 to Figure 8 As shown, on the opposite fixed side of the outer rotor type motor 8, a bearing 13 for supporting the output shaft 8a of the outer rotor type motor 8 is provided. The bracket 14 whose both ends are fixed to the frame material 11 is provided with this bearing 13 .

[0035] According to Embodiment 2, by holding both ends of the output shaft 8 a of the outer rotor type motor 8 , it is possible to improve the robustness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com