Filter core-type water circulation system for laser wet-cutting system and water circulation method therefor

A water circulation and filter element technology, which is applied in separation methods, laser welding equipment, chemical instruments and methods, etc., can solve the problems of high environmental damage and high content, and achieve the effect of reducing water consumption, fewer parts, and good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

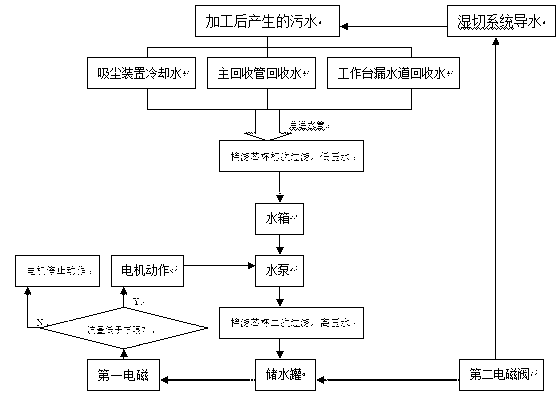

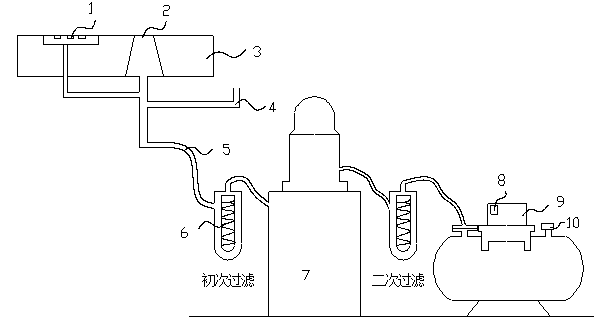

[0020] according to figure 1 In the water circulation process of the water circulation system shown, the sewage generated during the laser wet cutting process mainly comes from: the cooling water of the dust collection device, the recovery water of the main recovery pipe, and the recovery water collected by the leakage channel of the workbench; the above sewage all enters the main water inlet pipe Then it reaches the cotton filter cup for primary filtration, and the filtered low-pressure water enters the water tank and water pump in turn; then reaches the filter cup for secondary filtration, and the filtered high-pressure water is stored in the water storage tank. The first solenoid valve controls the stop and action of the motor by comparing the water flow with the upper and lower limits; when the flow is higher than the upper limit, the motor is controlled to stop moving; when the flow is lower than the lower limit, the motor is controlled to act; the second solenoid valve I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com