Rotary magneto-rheological damper

A magneto-rheological damper, rotary technology, applied in the direction of non-rotational vibration suppression, shock absorber, shock absorber, etc., can solve the problems of small maximum damping force, difficult sealing, few patents, etc., to achieve adjustable The effect of damping force, large damping force and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

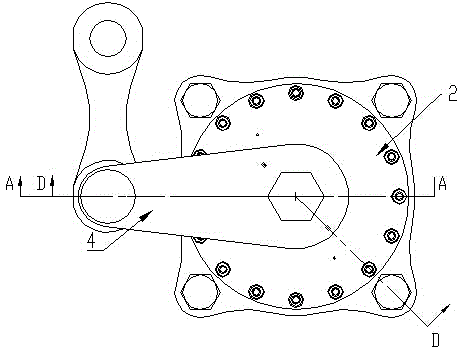

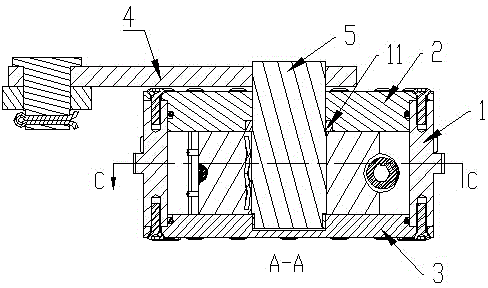

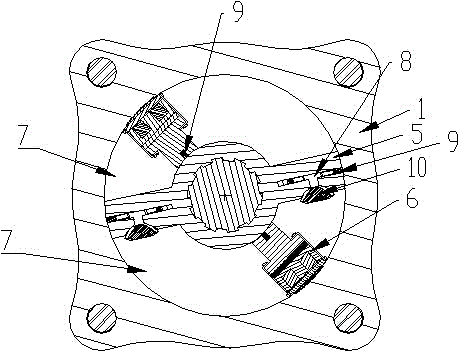

[0024] A rotary magneto-rheological damper, including a cylinder 1, an upper end cover 2, a lower end cover 3, a stator 4, a rotor blade 5, a magnetic circuit 6 and a rocker arm connected to the stator outside the upper end cover 2, and upper and lower end covers 2.3. The stator 4 and the cylinder 1 are sealed with a static seal O-ring. The upper end cover 2 is provided with wire holes and exhaust holes. The rotor blade 5 can rotate around the stator 4. The rotor blade 5 is connected to the upper end. The cover 2 and the lower end cover 3 are dynamic seals, which divide the cylinder body into two sealed spaces 7, and the magnetic circuit 6 is respectively arranged in the two sealed spaces 7, and is dynamically sealed with the root of the rotor blade 5 and the cylinder barrel 1, and is connected with the upper and lower end covers 2, 3 fixed seal. The sealing of upper and lower end covers 2, 3, stator 4 and cylinder 1 adopts static sealing O-rings. The dynamic sealing between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com