Manual safety device based on driving hammer type emission pistol

A safety device and hammer technology, which is applied in the field of firearms, can solve the problem of single safety status of pistols, and achieve the effects of fewer parts used, improved safety, and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with drawings and embodiments.

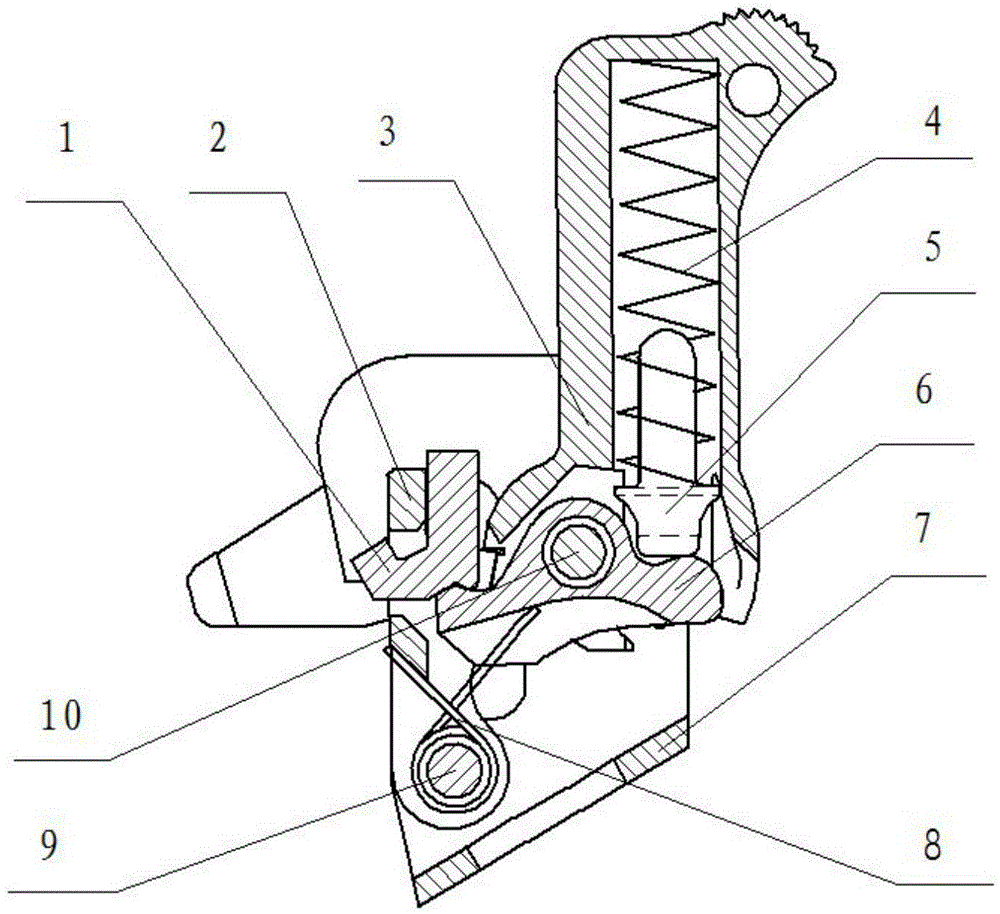

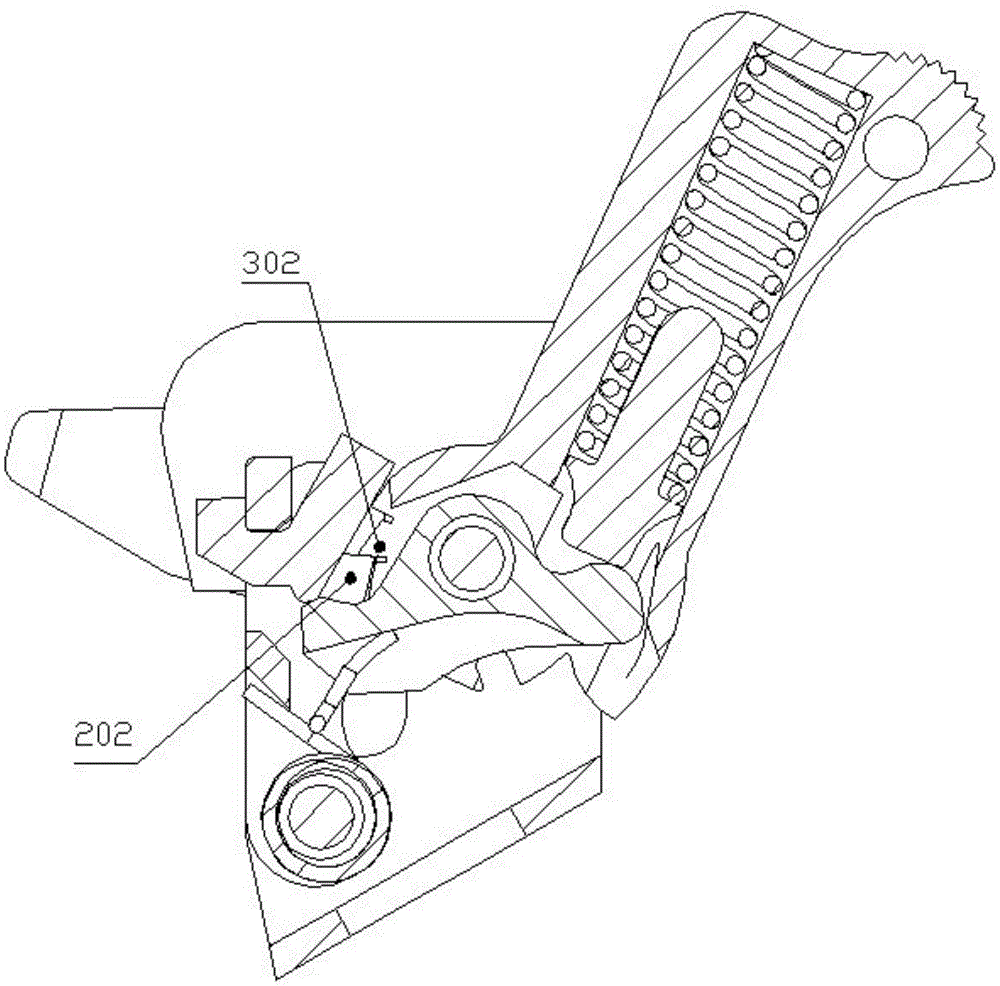

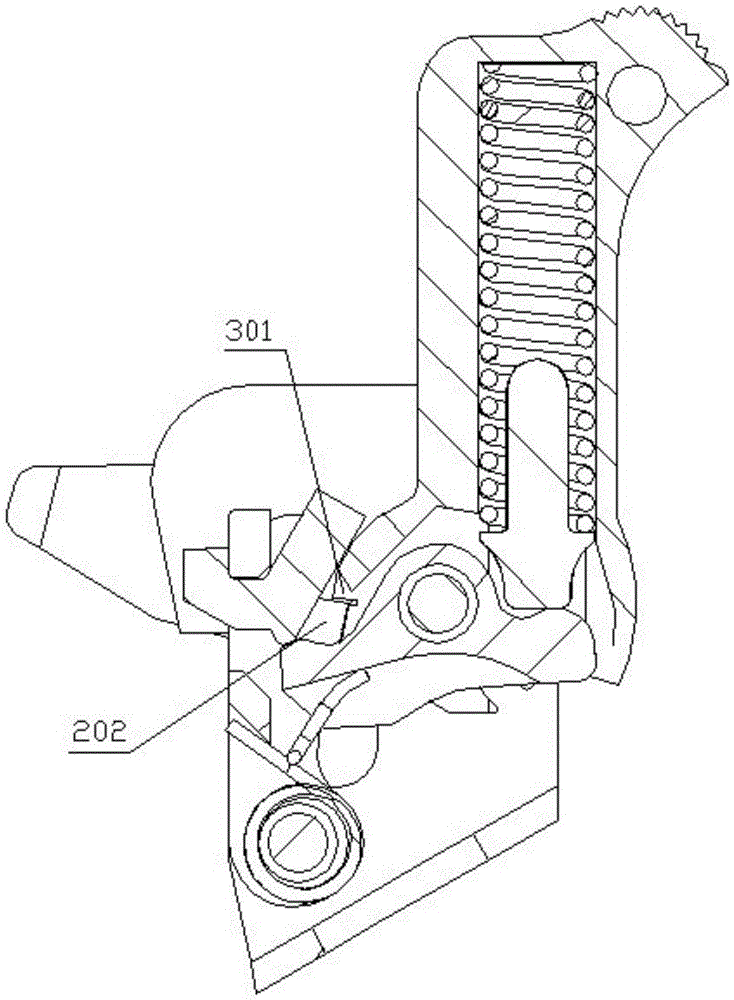

[0046] Such as figure 1 As shown, a manual safety device based on a hammer-type firing pistol, including a manual safety 1, a sear 2, a hammer 3, a hammer spring 4, a hammer spring rod 5, a hammer spring seat 6, and a transmitter seat 7 , Anti-iron spring 8, first shaft 9, second shaft 10. Such as Figure 12 As shown, the transmitter base 7 is roughly U-shaped, and it is fixedly installed on the pistol grip. The two side walls of the transmitter base 7 are symmetrically provided with safety mounting holes 701, and the two side walls of the transmitter base 7 are A relief hole 702 is also provided symmetrically. The relief hole 702 is located below the safety installation hole 701 . The first shaft 9 and the second shaft 10 are fixedly arranged between the two side walls of the transmitter base 7, the first shaft 9 is located at the bottom left of the second shaft 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com