A painting mechanism of chopsticks painting machine

A technology of chopsticks and lacquer machine, which is applied to the device and coating of surface coating liquid, can solve the problems of low processing efficiency, high production cost, high labor intensity of workers, etc., and achieve uniform painting and high painting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

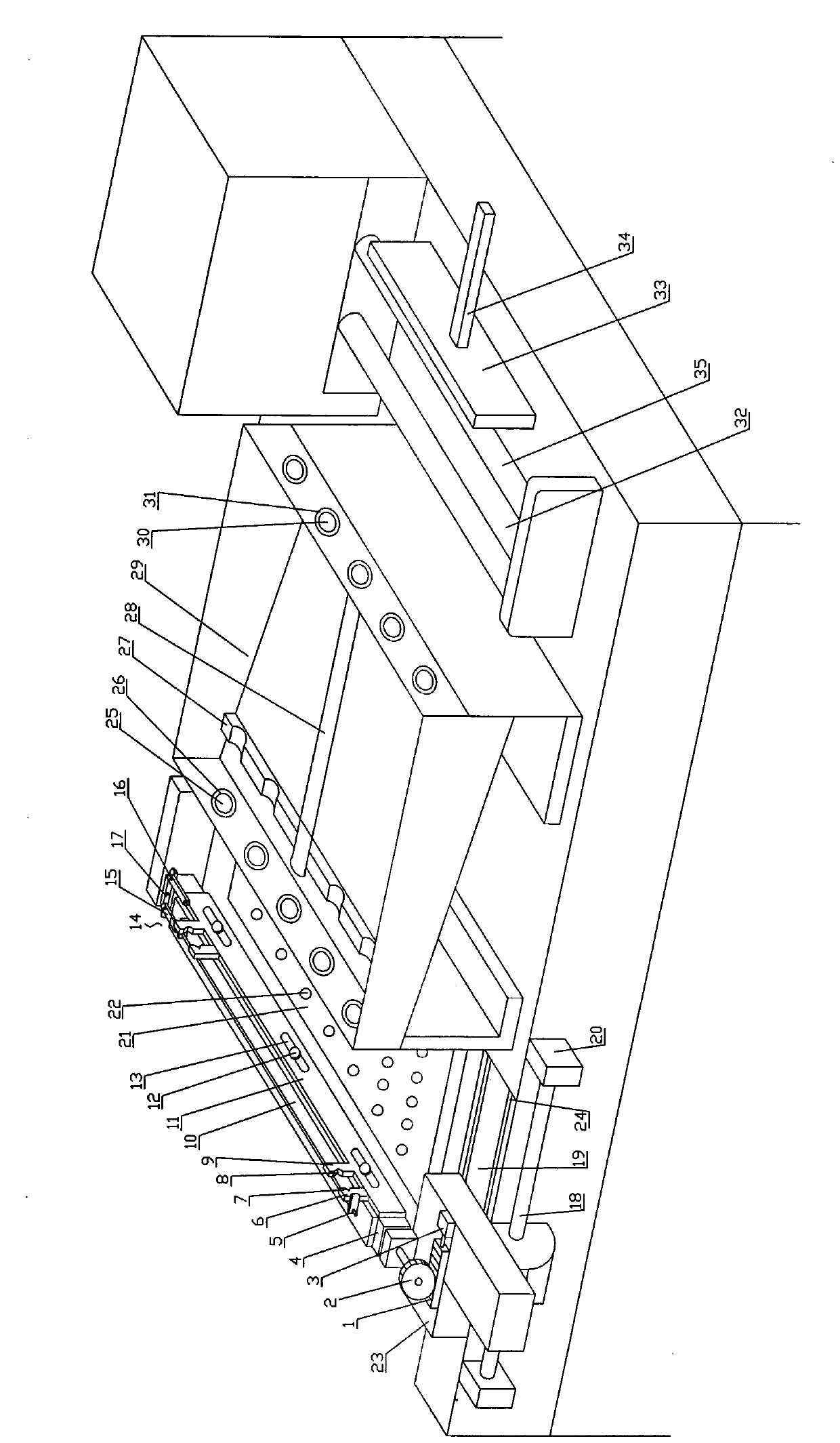

[0020] With reference to accompanying drawing, the painting mechanism of this kind of chopsticks painting machine comprises organic frame 19 and paint box 29, and the front end surface and rear end surface of described paint box are provided with chopsticks inlet hole 30 and chopsticks outlet hole 25 respectively, so The chopsticks entry holes 30 and the chopsticks exit holes 25 are provided in one-to-one correspondence, and at least two of the chopsticks entry holes 30 and the chopsticks exit holes 25 are arranged horizontally. figure 1 , the chopsticks entry hole and the chopsticks exit hole described in the present embodiment are provided with five, and the width of described lacquer box 29 is less than the length of chopsticks, makes the tail end of chopsticks after chopsticks enters lacquer box 29 and chopsticks entry hole 30 is blocked, Make the paint in the paint box 29 not to overflow, and when the next chopstick enters, the head end of the chopstick in the paint box wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com